Perma Pure GASS-2040 User Manual

Page 16

16

GASS-2040 User Manual | Original Instructions

4.4 Preheating the System

1.

Turn on AC power to the system.

2. Adjust purge air flow to 20-30 liters per minute.

3. Set purge air eductor vacuum level to 5 in-Hg (This is necessary only if the sample gas pres-

sure upstream of the GASS2040 is below atmosphere and more than 10 in-H2O vacuum)

4. Allow 15 - 30 minutes of additional heating time after system has come to set- point tempera-

ture.

5. Sample flow may now be started. For GASS-2040 systems that include a sample pump, the

pump will turn on if the pump switch is in the “AUTO” position.

The sample pump can be turned

off externally via the Remote Pump Shut-off input to the PLC. Refer to the I/O Wiring section

for connection details on page 11 and the electrical wiring diagram in the appendix.

4.5 Automatic Filter Drain Operation (Optional)

Adjust the drain cycle time as described in the Operator interface section on page 14.

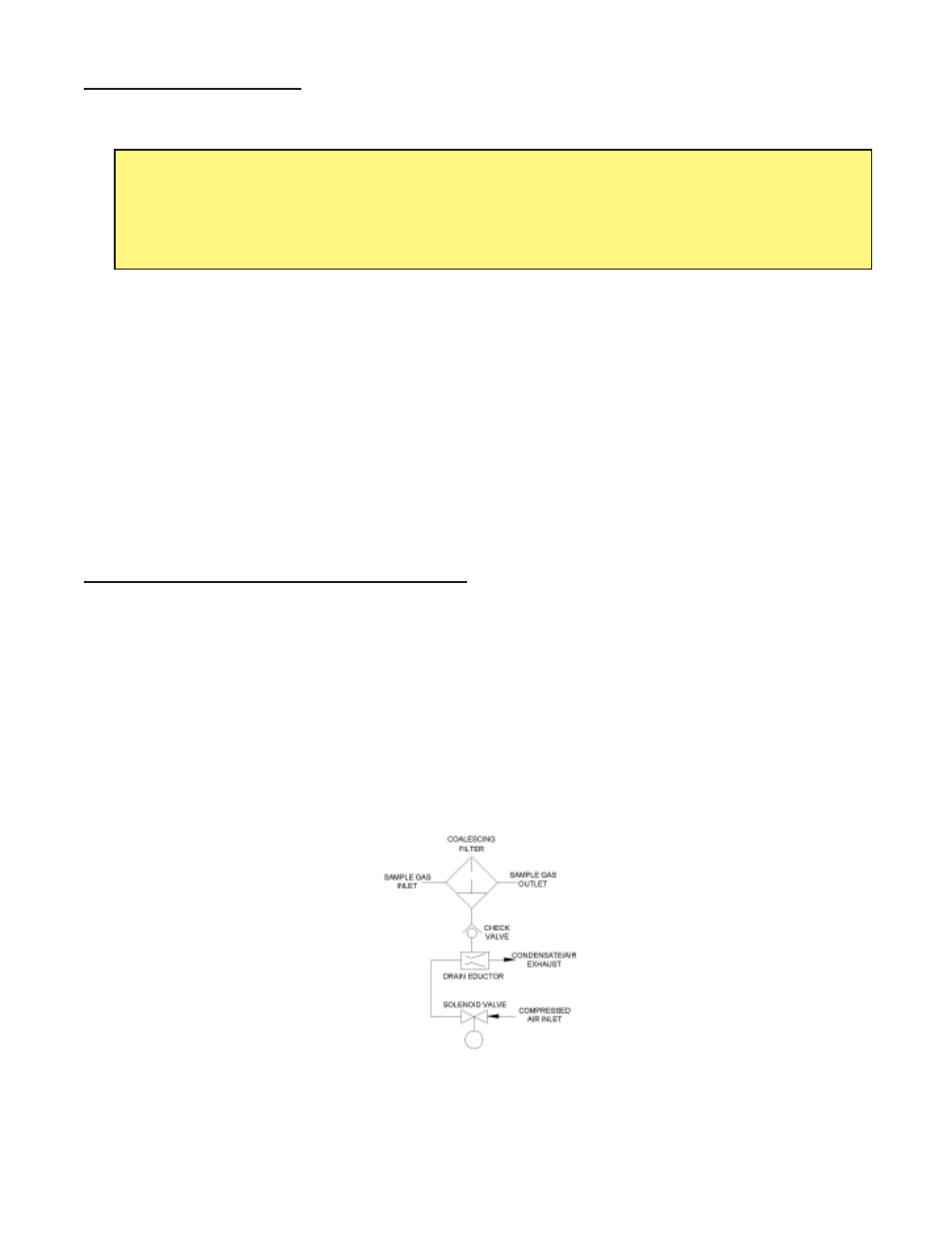

When the sample gas is under a vacuum, an eductor is used to generate enough vacuum to

remove condensate in the filter (See Figure 8). This is the most common configuration as the

sample pump is most typically located downstream of the sample conditioning system. Since the

sample gas is being pulled through the system, some amount of vacuum will be present in the filter

and a higher vacuum will be required to expel condensate from the filter. When the drain timer in

the PLC times out, a solenoid valve energizes and allows compressed air to flow to the drain

eductor for 6 seconds. In turn, the eductor generates vacuum to expel condensate.

DO NOT BEGIN SAMPLE FLOW AT THIS TIME! Check for purge air flowing from the exhaust

port immediately after turning on AC power. If, for any reason, there is no purge air or flow is

inadequate, turn off AC power before attempting to locate the problem. OPERATING THE

SYSTEM WITH LITTLE OR NO PURGE AIR CAN CAUSE DAMAGE TO MEMBRANE DRYER

ASSEMBLY.

Figure 8