Voltage drop test, Regulator charging voltage, Alternator output test – GxT V040-01, Battery Tester User Manual

Page 6

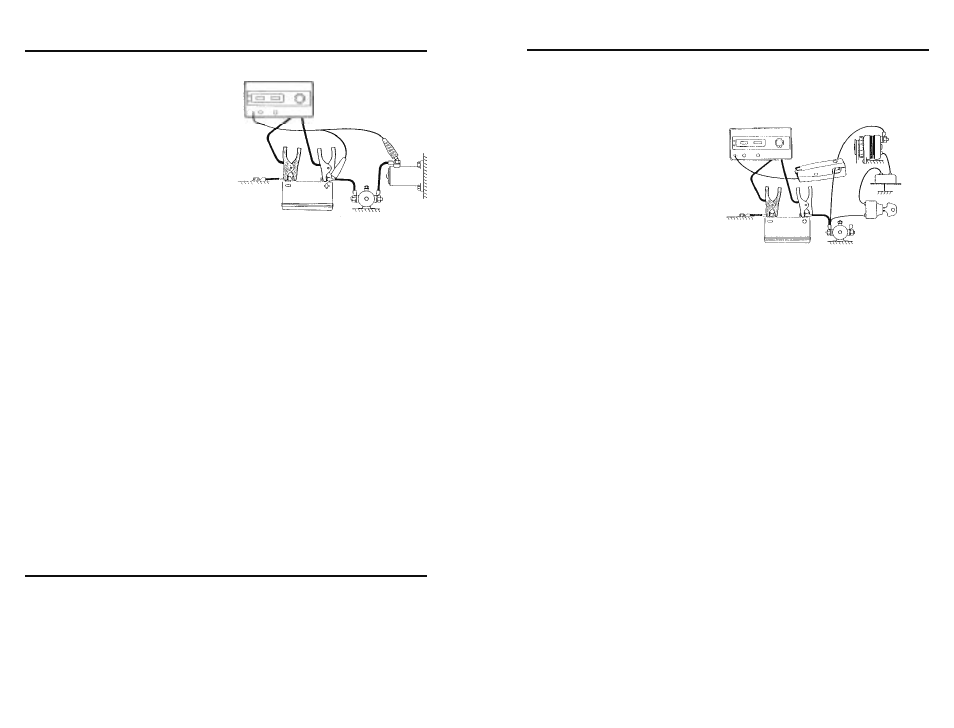

VOLTAGE DROP TEST

The voltage drop test is a very helpful diagnostic test for deter-

mining the condition of cables

and connections for the starting

charging circuit. The voltage drop

test can be used on any part of

the circuit. In the example below,

we are checking the entire circuit

from the positive side of the bat-

tery to the starter.

1. Be sure the Load Knob is

turned to OFF before con-

necting the analyzer cables to the battery. Take note of the

safety precautions on the back cover of this manual.

2. Connect the analyzer Battery Clamps to the battery termi-

nals; Red to positive, Black to negative.

3. Select external volts.

4. Connect the external volts leads as shown in the illustration.

Connect the Red auxiliary lead to the positive side of the

battery. Connect the Black lead to the input terminal of the

starter.

5. Disable ignition to prevent the engine from starting during the

test.

4. Operate the Starter and read the voltmeter while cranking.

5. Test Conclusions. Good circuits drop less than 0.50 volts on

a 12 volt system. Typically you should not have more than

0.10 volts drop per connection.

BATTERY

RED

BLACK

STARTER

SOLENOID

RELAY

CHASSIS

Connections For

INSULATED - POS CURCUIT TEST

POS

REGULATOR CHARGING VOLTAGE

Follow the same setup and test procedure used for the alterna-

tor test, except put the Amp Probe around either battery cable.

Once the charging amperage drops below 20 amps, the voltage

displayed will be the regulator setting. This should be between

13.5 and 15.5 volts on a 12 volt system.

BATTERY

ALTERNATOR

OUT

FIELD

REGULATOR

KEY SWITCH

CHASSIS

Connections For

AMPERAGE OUTPUT TEST

ALTERNATOR OUTPUT TEST

Always compare test results with manufacturer’s specifications

before coming to conclusions regarding the performance or ef-

ficiency of charging systems and their components

1. Be sure the Load Knob is

turned to OFF before con-

necting the analyzer cables

to the battery. Take note

of the safety precautions

on the back cover of this

manual.

2. Connect the analyzer Bat-

tery Clamps to the battery

terminals; Red to positive, Black to negative.

3. With the Amp Probe jaws closed and not around any wires,

press the Zero Amps buttons until the Amps Display shows

“000”

4. Place the Amp Probe around the alternator output wire. Try

to position the probe away from strong magnetism near the

back shaft end of the alternator to avoid measurement error.

5. Display Battery Volts.

6. Start and run the engine at about 2000 RPM.

7. Turn the Load ON and increase until the battery voltage

decreases to be between 12 and 13 volts while reading the

output amperage.

8. Turn Load OFF and reduce RPM.

9. Test Conclusions

a. If the Amps Ripple lamp stayed on during the output test

replace the alternator.

b. If the amperage abruptly decreased during the test check

for a loose belt.

c. If output was less than 90% of rating use the voltage drop

test to check output resistance.

d. If output did not change, full field the alternator. If the

alternator output increases, replace the regulator.