Hubbell Lifting Magnet Controllers 4292 User Manual

Lifting magnet controllers, Features, Hubbell industrial controls, inc

Hubbell Industrial Controls, Inc.

Lifting Magnet Controllers

Specification/Price Sheet • August 2008 • Replaces Jan 2008

4292

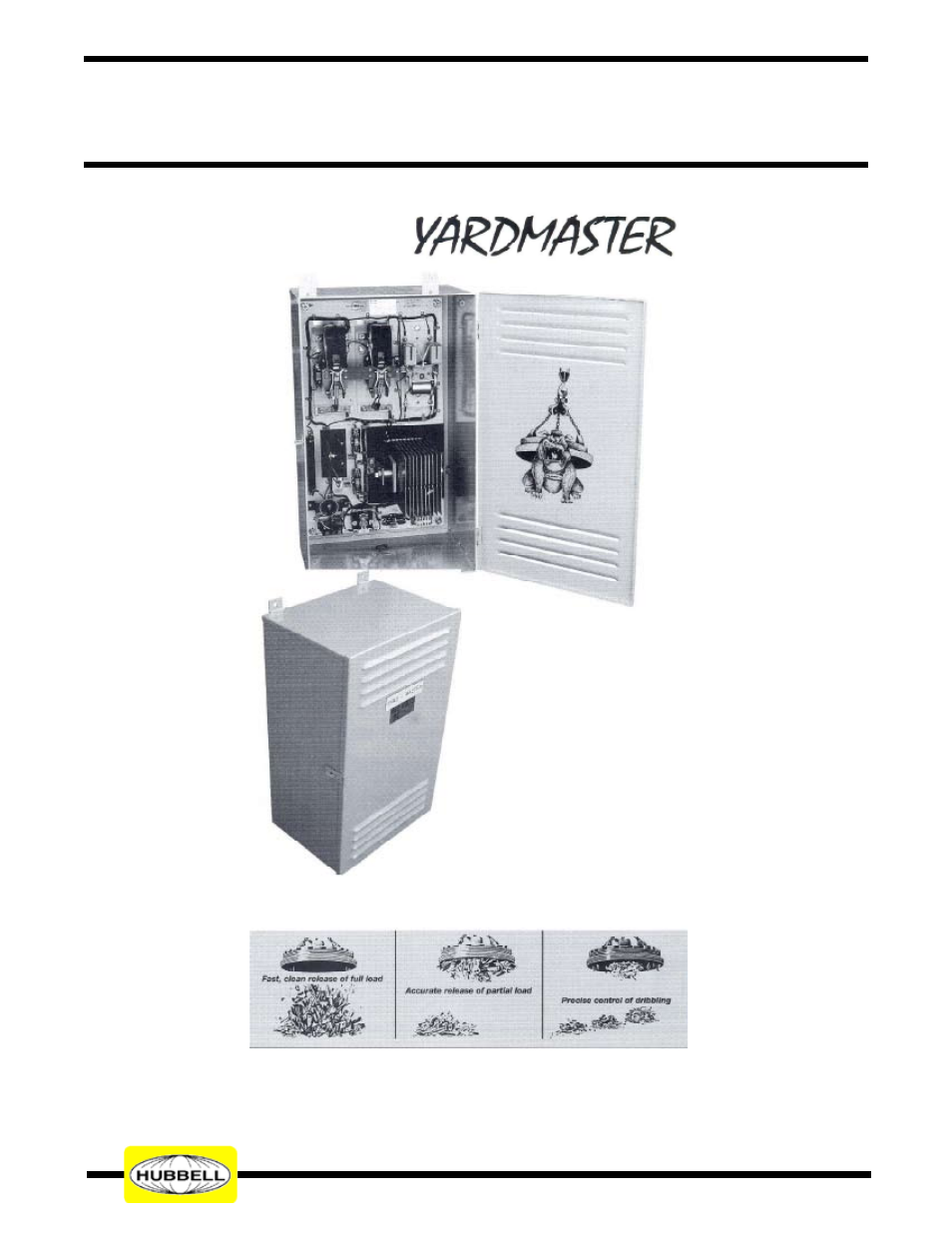

Type 4292 Compact Controller for Scrap Yards

Description

The Type 4292 Yard-

master

Controllers

incorporated heavy-duty

time proven components

arranged to provide

optimum control of your

lifting magnets.

A mechanically rugged

high thermal capacity

discharge

varistor

assembly is permanently

connected in parallel

with the magnet and

provides a safe dis-

charge path for the

stored magnetic energy.

With Yardmaster mag-

net controllers, induced

voltage cannot return

to the line, permitting

rectified power supplies

to be used without

the added expense of

special protective loads

or bypass circuits.

Application

The Type 4292 Yard-

master Controllers are

suited for many uses

from light scrap handling

to the handling of heavy

billets or plates. It may

be used with all types

and makes of DC lifting

magnets.

Automatic

Discharge

Type

Controllers

The Type 4292 Yardmaster

Automatic Discharge Type

Lifting Magnet Controller

provides a fast and clean

release of mag-net loads

by applying full voltage

reverse current to the

magnet. The full voltage

re-verse current feature

permits the operator to

promptly return for another

lift.

The drop contactor is

under the control of the

operator’s Master Switch

and the dis-charge sensor

module (DSM). When

the operator’s Master

Switch signals the magnet

controller to drop the load,

the “Lift” contactors (L)

open. The stored magnet

energy is dissipated in the

dis-charge varistor. When

the discharge voltage

declines to approximately

300V, the DSM energizes

the drop relay (DR) which

in turn enables the drop

contactor (D) to close

applying full voltage reverse

cur-rent to the magnet and

begin the adjust-able time

reverse current cycle. After

the completion of the timed

reverse cycle the drop

relay and drop contactor

are deenergized.

Features

Automatic Discharge

•

Rated 250 VDC @ 5-100 amps

•

Front-Wired Front-Removable components

•

Mechanically interlocked “Lift” and “Drop”

•

NEMA rated mill duty contactors

Permanently connected 700V discharge

•

path completely independent from the

line that protects magnet and generator

High-Thermal capacity varistor discharge

•

path

Peak magnet induced voltage limited to

•

under 700 Volts

Long electrical contact life

•

Minimum Maintenance

•

Dribble control - Standard

•

Ventilated indoor/outdoor NEMA 3R

•

enclosure