Air supply, Safety ser vice opera tion techniques setup – Harbor Freight Tools 95136 User Manual

Page 7

Page 7

For technical questions, please call 1-800-444-3353.

SKU 95136

SAFETY

SER

VICE

OPERA

TION

TECHNIQUES

SETUP

Air Supply

TO PREVENT SERIOUS INJURY FROM EXPLOSION:

Use only clean, dry, regulated, compressed air with this tool.

Do not use oxygen, acetylene, carbon dioxide, combustible gases,

or any other bottled gas as a power source for this tool.

1.

Incorporate a filter, regulator with pressure gauge,

dryer, in-line shutoff valve, and quick coupler for

best service, as shown on Figure A on page 8

and Figure B on page 9.

An in-line shutoff

ball valve is an important safety device because

it controls the air supply even if the air hose

is ruptured. The shutoff valve should be a

ball valve because it can be closed quickly.

Note: An oiler system should not be used with

this tool. The oil will mix with the material

being propelled, causing poor results.

2.

Attach an air hose to the compressor’s air outlet.

Connect the air hose to the air inlet on the back

of the Plasma Cutter. Other components, such

as a coupler plug and quick coupler, will make

operation more efficient, but are not required.

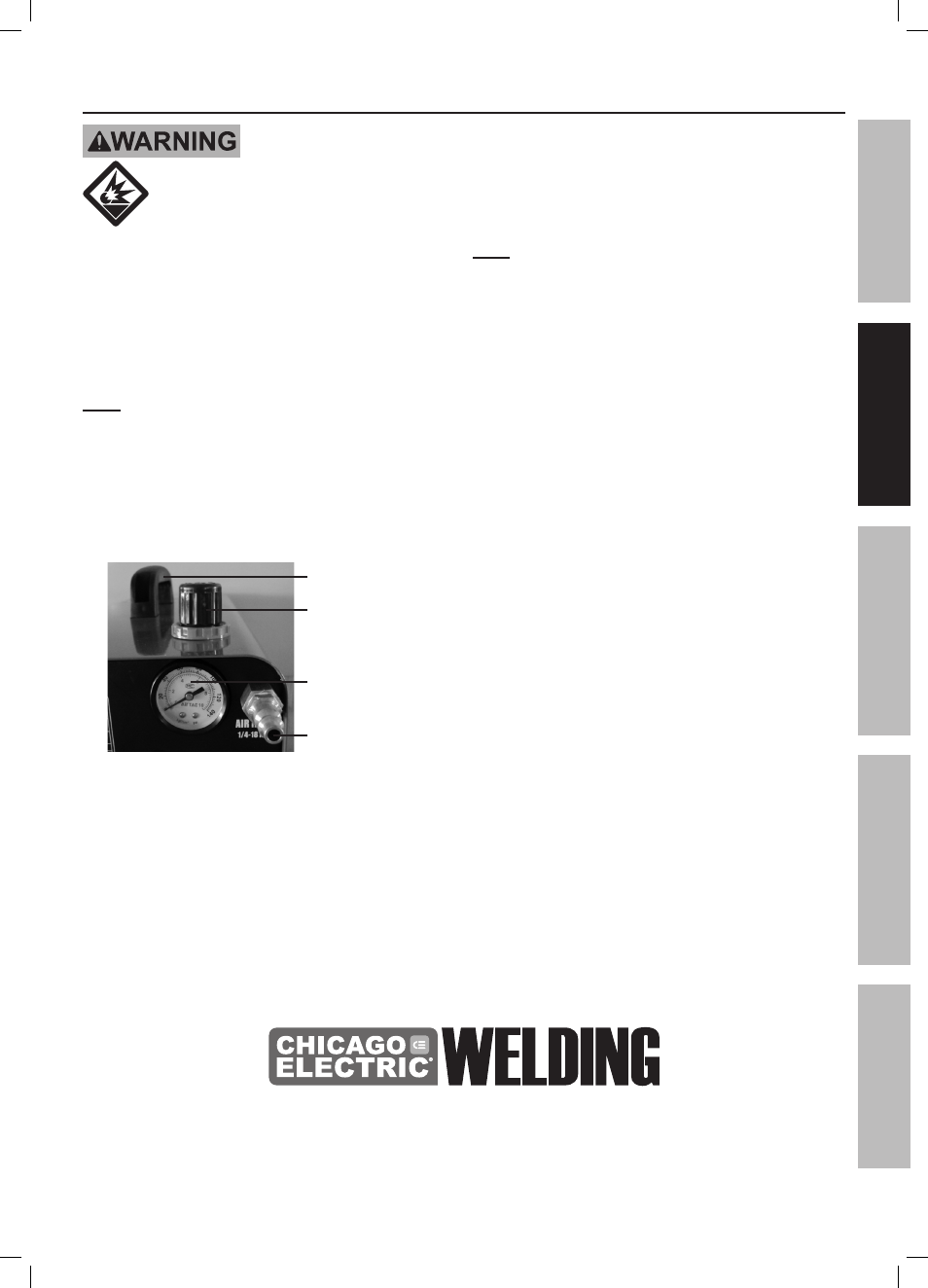

Handle

Air pressure

regulator knob

Air inlet

Air pressure gauge

Note: Air flow, and therefore tool performance, can

be hindered by undersized air supply components.

The air hose must be long enough to reach

the work area with enough extra length to

allow free movement while working.

3.

Turn the tool’s switch to the off position; refer to

Operation section for description of controls.

4.

Close the in-line shutoff valve between

the compressor and the tool.

5.

Turn on the air compressor according to

the manufacturer’s directions and allow it

to build up pressure until it cycles off.

6.

Adjust the air compressor’s output regulator so

that the air output is enough to properly power

the tool, but the output will not exceed the tool’s

maximum air pressure at any time (60-80 PSI).

Adjust the pressure gradually, while checking the

air output gauge to set the right pressure range.

7.

Inspect the air connections for leaks.

Repair any leaks found.

8.

If the tool will not be used at this time, turn off

and detach the air supply, safely discharge

any residual air pressure, and release

the throttle and/or turn the switch to its off

position to prevent accidental operation.