Controls and indicators, Preparing your work area, Safety ser vice opera tion techniques setup – Harbor Freight Tools 95136 User Manual

Page 10: Operating instructions

Page 10

For technical questions, please call 1-800-444-3353.

SKU 95136

SAFETY

SER

VICE

OPERA

TION

TECHNIQUES

SETUP

Operating Instructions

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this manual

including all text under subheadings therein before set up or use of this product.

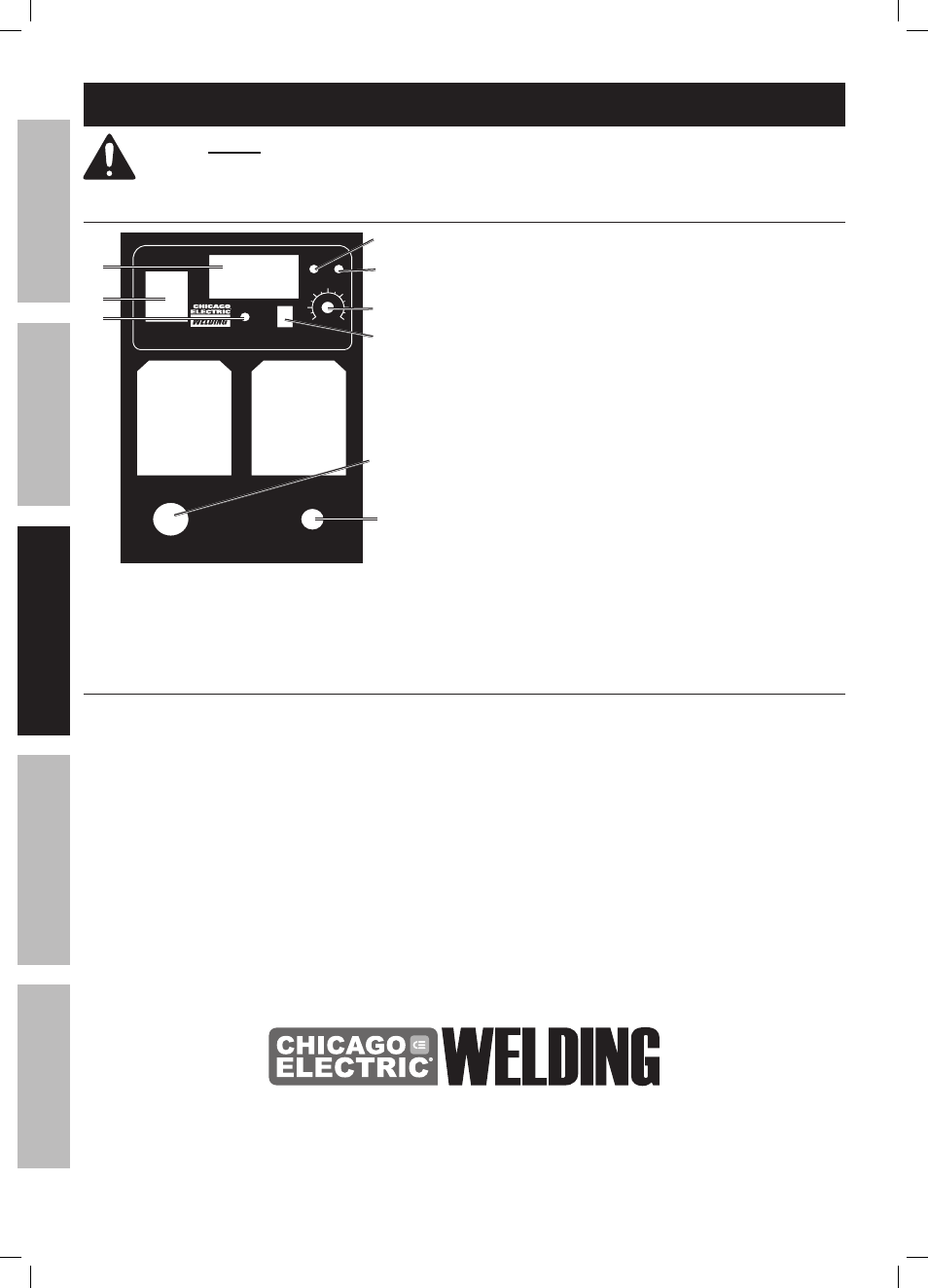

Controls and Indicators

POWER

ON

POWER

WORKING

AIR

CURRENT

MIN

MAX

SET

CUTTER

OVER-

HEAT

OFF

240 VOLT INVERTER PLASMA CUTTER

with Digital Display

ITEM 95136

GROUND

TORCH

1

2

3

4

5

6

7

Torch

Connector

Ground

Connector

1.

Power Switch.

Up is ON, down is OFF.

2.

Digital Amp Meter.

Shows actual cutting current,

which will vary during operation.

3.

Thermal Overload Indicator Lamp.

This light will come on, and the device will

shut down if the tool becomes overheated.

Stop trying to use the cutter while leaving the

power switch ON to allow the cooling fan to

operate, and the lamp will turn off automatically

when the machine cools down.

Pay attention to Duty Cycle discussed on page 6.

4.

Power ON Light.

5.

Power Supply Controller.

6.

Mode Selector.

Turns the air supply ON prior to cutting.

7.

Working Indicator Light.

Will be on during cutting operation.

Preparing Your Work Area

1.

You must have a sturdy work table that is

open below the area you are cutting. Molten

slag will be blown through the work metal,

and must be able to fall away freely.

2.

Your work table must allow the work metal to be firmly

clamped to prevent it accidentally falling or moving.

3.

The floor and surrounding area of your work site

must not be flammable. A clean cement floor is

recommended. The cutting process will eject

molten metal slag onto the floor, and it will scatter

for 8-10 feet or more in any direction. Have an

adequate fire extinguisher available if needed.