Troubleshooting (cont.), Safety ser vice opera tion techniques setup – Harbor Freight Tools 95136 User Manual

Page 15

Page 15

For technical questions, please call 1-800-444-3353.

SKU 95136

SAFETY

SER

VICE

OPERA

TION

TECHNIQUES

SETUP

Troubleshooting (cont.)

Check that the grounding point and

the metal being cut are both clean, dry,

and free from all coatings and paint.

These sections need to be able to

conduct electricity efficiently.

Air pressure too high or too low.

Check the Air Pressure setting

on the regulator’s gauge.

Adjust the Air Regulator

to deliver only 60-80 PSI

to the Cutter.

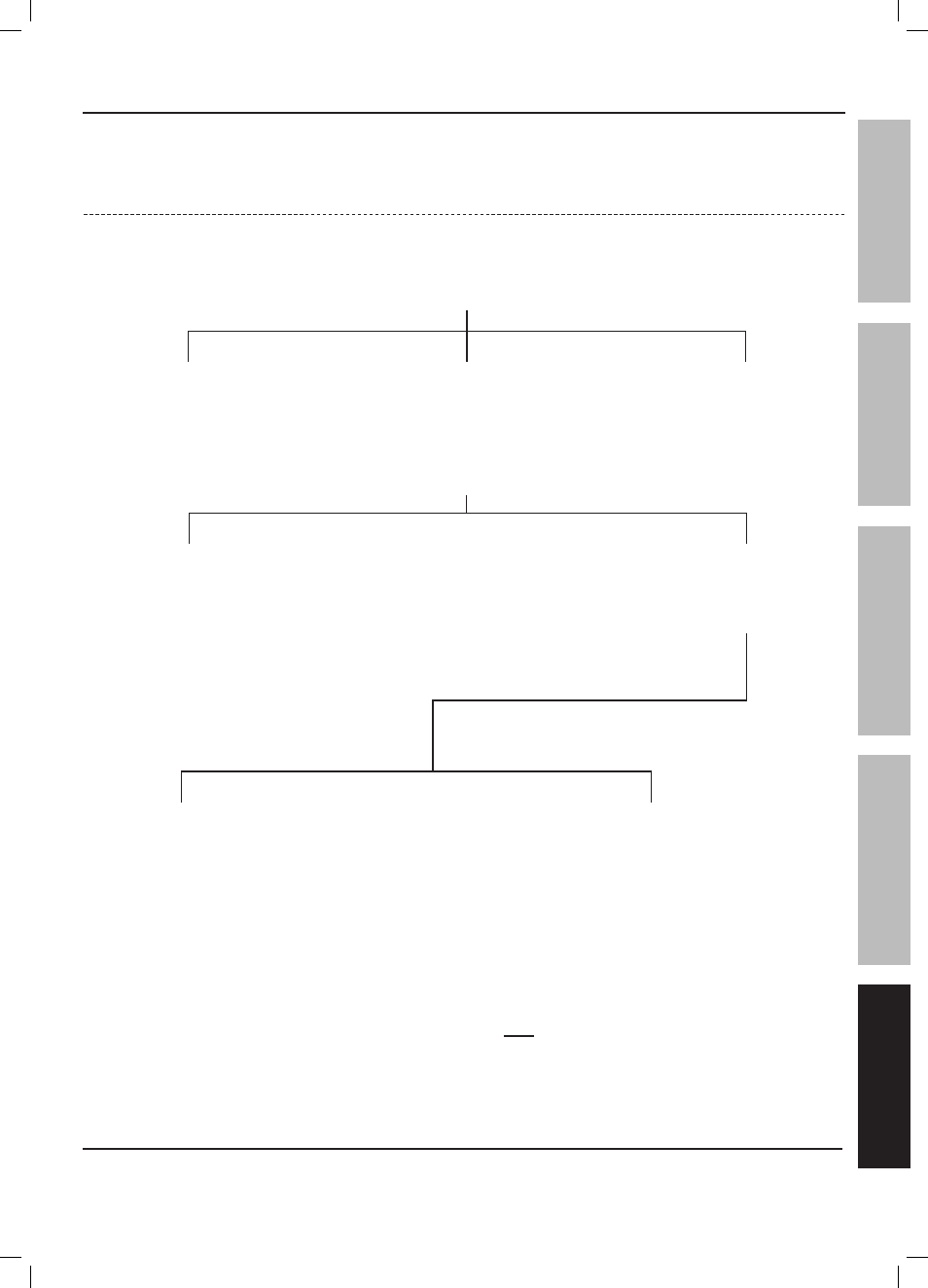

ARC IGNITES FOR SEVERAL SECONDS BUT THEN GOES OUT

AIR PRESSURE

TOO HIGH

AIR PRESSURE

TOO LOW

a. Verify that the compressor

is delivering at least

3.5 CFM @ 80 PSI.

b. Set Regulator on the

unit to at least 60 PSI.

Use a wire wheel brush or sander

(not included) to thoroughly

clean both the grounding point

and the area that will be cut.

If any cleaners are used, allow them

to dry thoroughly before continuing.

DIRTY OR

COATED METAL

Check that all air and electrical

connections are tight.

METAL IS CLEAN IN

BOTH AREAS

Shut off switch,

if not off already, and

tighten connections.

If connections do not

tighten properly, contact

a qualified technician.

LOOSE

CONNECTIONS

Torch isn’t maintaining contact with the workpiece.

a. Be careful to not lose workpiece

contact after an arc is struck.

b. Disconnect the Torch Cables.

Disassemble the torch assembly and

inspect all internal components.

Replace any damaged or missing

components and reassemble carefully,

following the steps on page 11.

DO NOT OVERTIGHTEN.

c. Nozzle is moving too slowly across

the metal and cutting the material from

underneath, breaking contact.

AIR PRESSURE

CORRECT

TIGHT

CONNECTIONS

IMPORTANT!

Be CERTAIN to shut off the Plasma Cutter, and disconnect it from power and air before adjusting, cleaning, or

repairing the unit. A technician should discharge all capacitors before performing any internal procedures.

If the steps above do not solve the problem or if the repairs involved are too complex,

contact a qualified technician.