Harbor Freight Tools GREYHOUND 65761 User Manual

Page 12

SKU 65761

For technical questions, please call 1-800-444-3353.

Page 12

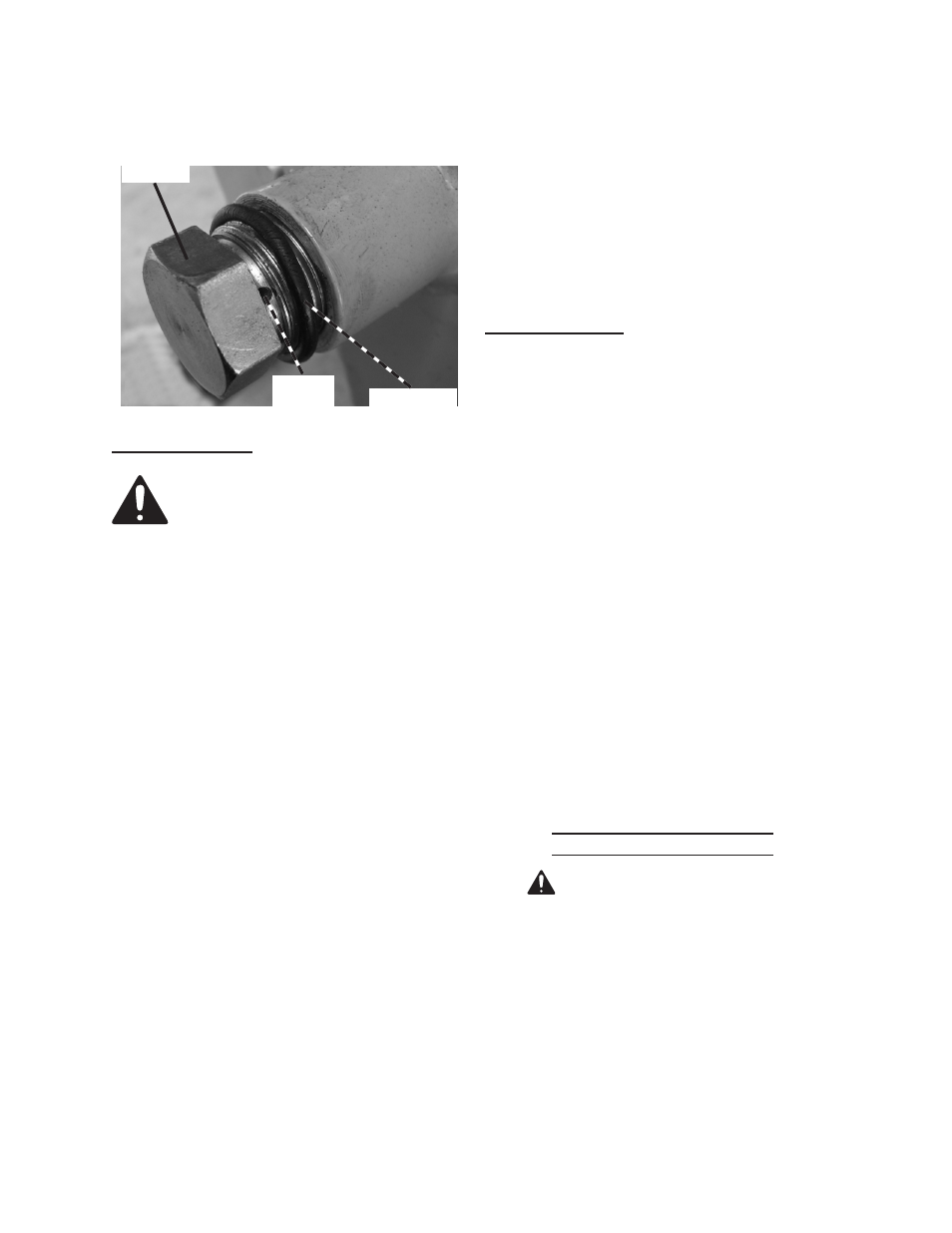

air inlet hole by tightening the Plug,

as shown below.

plug (37)

o ring (21)

air inlet

Hole

start procedure

Before starting the engine:

Follow the set up instruc-

a.

tions to prepare the equip-

ment.

inspect the equipment and

b.

engine.

Fill the engine with the prop-

c.

er amount and type of fuel

and oil.

read the equipment opera-

d.

tion section that follows.

Turn the engine fuel valve to its

1.

“OPEN” position.

Turn the engine power switch to its

2.

ON or RUN position.

Then, turn the engine choke lever to

3.

its “CHOKE” position. Set the choke

lever in the “RUN” position when

starting a warm engine.

Grasp the starter handle, and pull

4.

slowly until resistance is felt. While

holding the handle, allow the starter

rope to rewind slowly. Then, pull the

starter handle with a rapid, full arm

stroke. Once again while holding

the handle, allow the rope to rewind

slowly. Repeat as necessary, until

the engine starts.

After the engine starts and warms

5.

up, slowly move the choke lever to its

“RUN” position.

IMPORTANT: Allow the engine to run

6.

at no load until warm (1-5 minutes).

Break-in period

Breaking-in the engine will help to

1.

ensure proper equipment and engine

operation, and will extend the en-

gine’s lifespan. The warranty is void

if the engine is not broken in properly.

The first 20 hours of operation is the

break-in period.

During the first 3 hours of use:

2.

Do not apply a heavy load to the

•

equipment.

Do not operate the engine at its

•

maximum speed.

After the first 20 hours of use:

3.

Change the engine oil.

•

Under normal operating conditions

subsequent maintenance follows the

schedule explained in the MAINTE-

NANCE AND SERVICING section.

equipment operation

1.

Warning! to avoid death or

serious injury; block each side of

both wheels of the Log Splitter before

starting a job.

In FIGURE 1, the Rail Assembly is

2.

shown in Horizon tal mode for opera-

tion and travel. In FIGURE 4 the unit

is shown in the vertical position. To

change positions, remove the Hair

Pin Clip (29) and the Push Pin (26).