16. common mig shielding gases – Hobart Welding Products HANDLER 140 OM-925 User Manual

Page 44

OM-925 Page 40

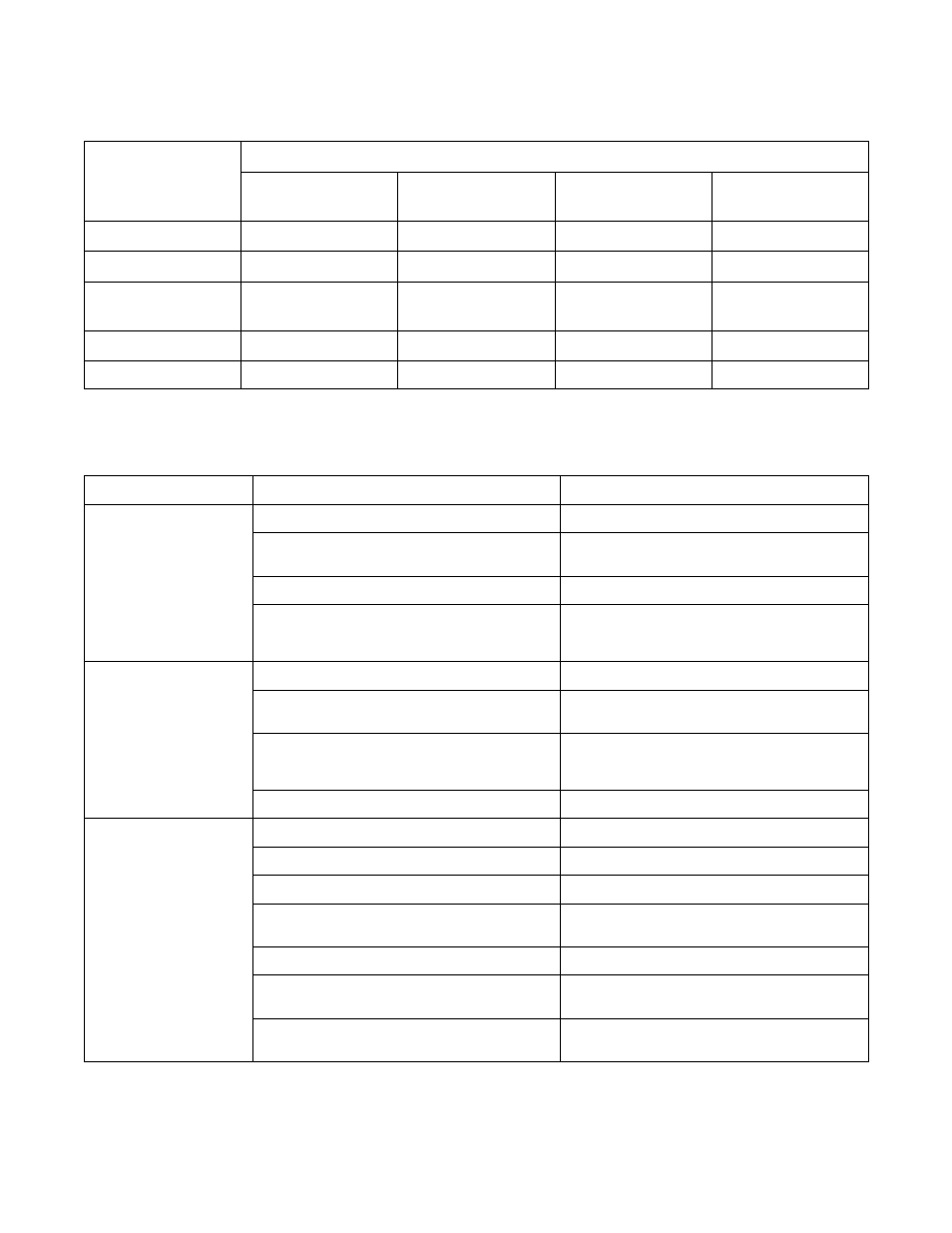

9-16. Common MIG Shielding Gases

This is a general chart for common gases and where they are used. Many different combinations (mixtures) of

shielding gases have been developed over the years. The most commonly used shielding gases are listed in the

following table.

Application

Gas

Spray Arc Steel

Short Circuiting Steel

Short Circuiting

Stainless Steel

Aluminum

Argon

X

Argon + 25% CO

2

X

80% or greater Argon +

balance CO

2

or Oxygen

X

X

1

100% CO

2

X

Tri-Mix2

X

1

Limited short circuiting use

2

90% HE + 7-1/2% AR + 2-1/2% CO

2

9-17. Troubleshooting Guide For Semiautomatic Welding Equipment

Problem

Probable Cause

Remedy

Wire feed motor operates, but

wire does not feed.

Too little pressure on wire feed rolls.

Increase pressure setting on wire feed rolls.

Incorrect wire feed rolls.

Check size stamped on wire feed rolls, replace to match

wire size and type if necessary.

Wire spool brake pressure too high.

Decrease brake pressure on wire spool.

Restriction in the gun and/or assembly.

Check and replace cable, gun, and contact tip if

damaged. Check size of contact tip and cable liner,

replace if necessary.

Wire curling up in front of the

wire feed rolls (bird nesting).

Too much pressure on wire feed rolls.

Decrease pressure setting on wire feed rolls.

Incorrect cable liner or gun contact tip size.

Check size of contact tip and check cable liner length

and diameter, replace if necessary.

Gun end not inserted into drive housing properly.

Loosen gun securing bolt in drive housing and push gun

end into housing just enough so it does not touch wire

feed rolls.

Dirty or damaged (kinked) liner.

Replace liner.

Wire feeds, but no gas flows. Gas cylinder empty.

Replace empty gas cylinder.

Gas nozzle plugged.

Clean or replace gas nozzle.

Gas cylinder valve not open or flowmeter not adjusted. Open gas valve at cylinder and adjust flow rate.

Restriction in gas line.

Check gas hose between flowmeter and wire feeder, and

gas hose in gun and cable assembly.

Loose or broken wires to gas solenoid.

Have Factory Authorized Service Agent repair wiring.

Gas solenoid valve not operating.

Have Factory Authorized Service Agent replace gas

solenoid valve.

Incorrect primary voltage connected to welding power

source.

Check primary voltage and relink welding power source

for correct voltage.