Maintenance and servicing the fireplace, Warning, A. general maintenance – Hearth and Home Technologies C-40 User Manual

Page 58

Page 58

Heatilator • Constitution EPA Fireplace • 480-1091C

November 11, 2008

11

Maintenance and Servicing the Fireplace

A. General Maintenance

Inspection: Inspect the system at the appliance connection

and at the chimney top. Cooler surfaces tend to build

creosote deposits quicker, so it is important to check the

chimney from the top as well as from the bottom.

Formation and Need For Removal: When wood is burned

slowly, it produces tar and other organic vapors which

combine with expelled moisture to form creosote. The

creosote vapors condense in the relatively cool chimney

flue of a newly-started or a slow-burning fire. As a result,

creosote residue accumulates on the flue lining. When

ignited, this creosote creates an extremely hot fire which

may damage the chimney or even destroy the house. The

chimney connector and chimney should be inspected once

every 2 months during the heating season to determine if a

creosote or soot buildup has occurred. If creosote or soot

has accumulated, it should be removed to reduce the risk

of a chimney fire.

1. Creosote (Chimney) Cleaning

• Frequency: As necessary; at least annually before lighting

stove or once every 2 months during heating

season.

• By: Homeowner / Chimney Sweep

• Task: See the following instructions.

Remove all ash from the firebox and extinguish all hot

embers before disposal. Allow the appliance to cool

completely. Disconnect flue pipe or remove baffle and

ceramic blanket from appliance before cleaning chimney.

Otherwise residue can pile up on top of the baffle and

ceramic blanket and the appliance will not work properly.

(See Baffle Removal on page 31). Close the door tightly.

The creosote or soot should be removed with a brush

specifically designed for the type of chimney in use. Clean

out fallen ashes from the firebox. A chimney sweep can

perform this service.

It is also recommended that before each heating season

the entire system be professionally inspected, cleaned and

repaired if necessary.

Asphyxiation Risk

Fire Risk

Annual inspection by qualified technician

recommended.

Check:

• Condition of doors, surrounds and fronts

• Condition of glass and glass assembly

• Obstructions of combustion and ventilation

air

• Obstructions of termination cap

Clean:

• Glass

• Air passageways, grilles

WARNING

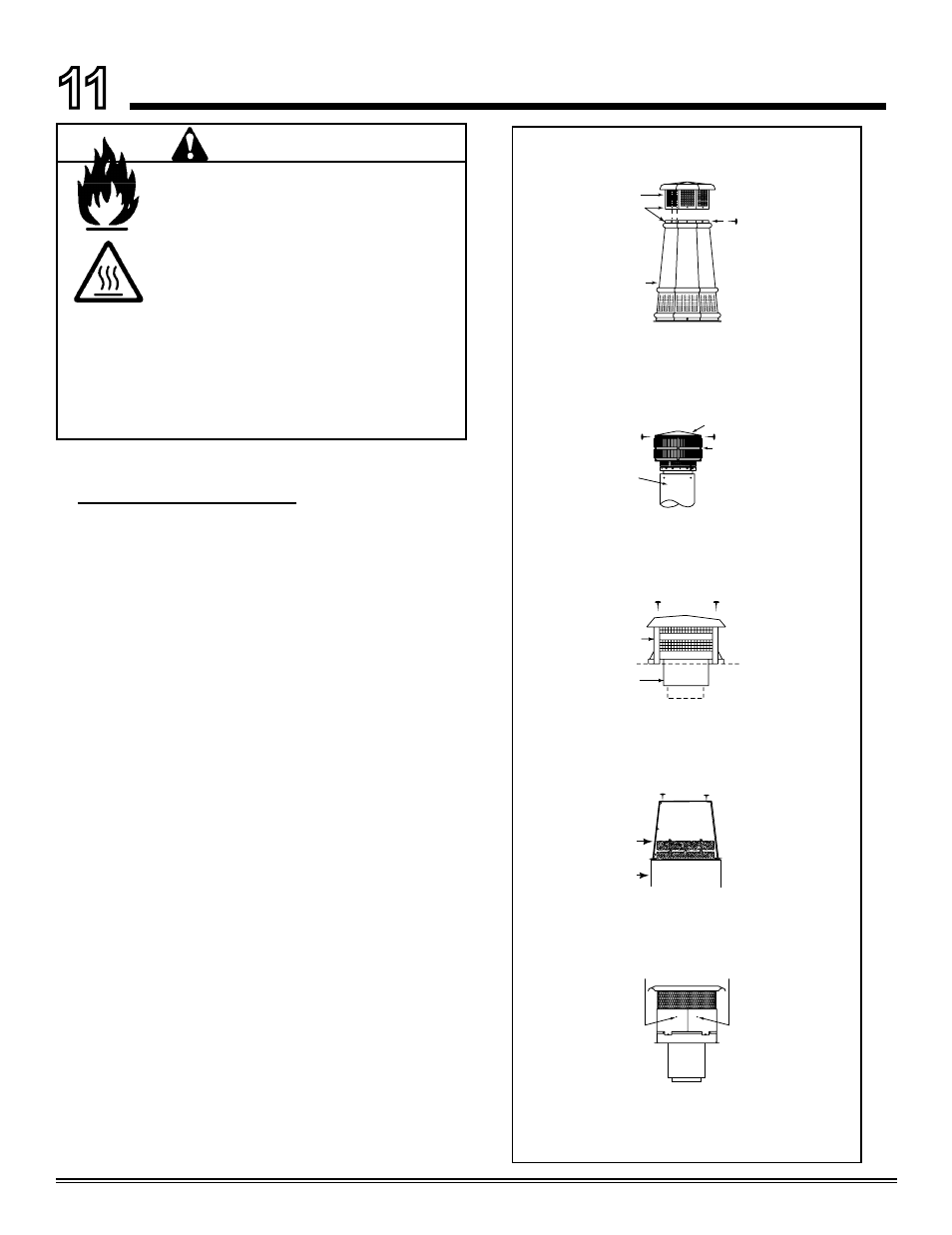

Figure 58.1 Chimney & Termination Cap Cleaning

Chimney

Remove 4 screws

and lift top pan off.

Cap

Slip

Section

ST375

Square

Termination Cap

Cap

Remove screws,

lift top cover.

Top Cover

TR344/TR342

Round

Termination Cap

Chase

Cap

1. Remove the 4 screws.

2. Remove the screen.

3. Remove the baffle.

TS345/TS345P

Square

Termination Caps

TCT375

Terra Cotta

Termination Cap

Remove 2 screws from

the front and back and

lift the top off.

Cap Top

(Be sure

holes in

cap top

and cap

base are

aligned.)

European Copper Series

Termination Cap

(CT3-King shown)

Cap Base

Remove 8 screws

(9 for King), lift top

cover.