Maintenance, Band wheel adjustment, Drive belt (fig. 63) – Husqvarna SMB 70 User Manual

Page 33

English –

33

MAINTENANCE

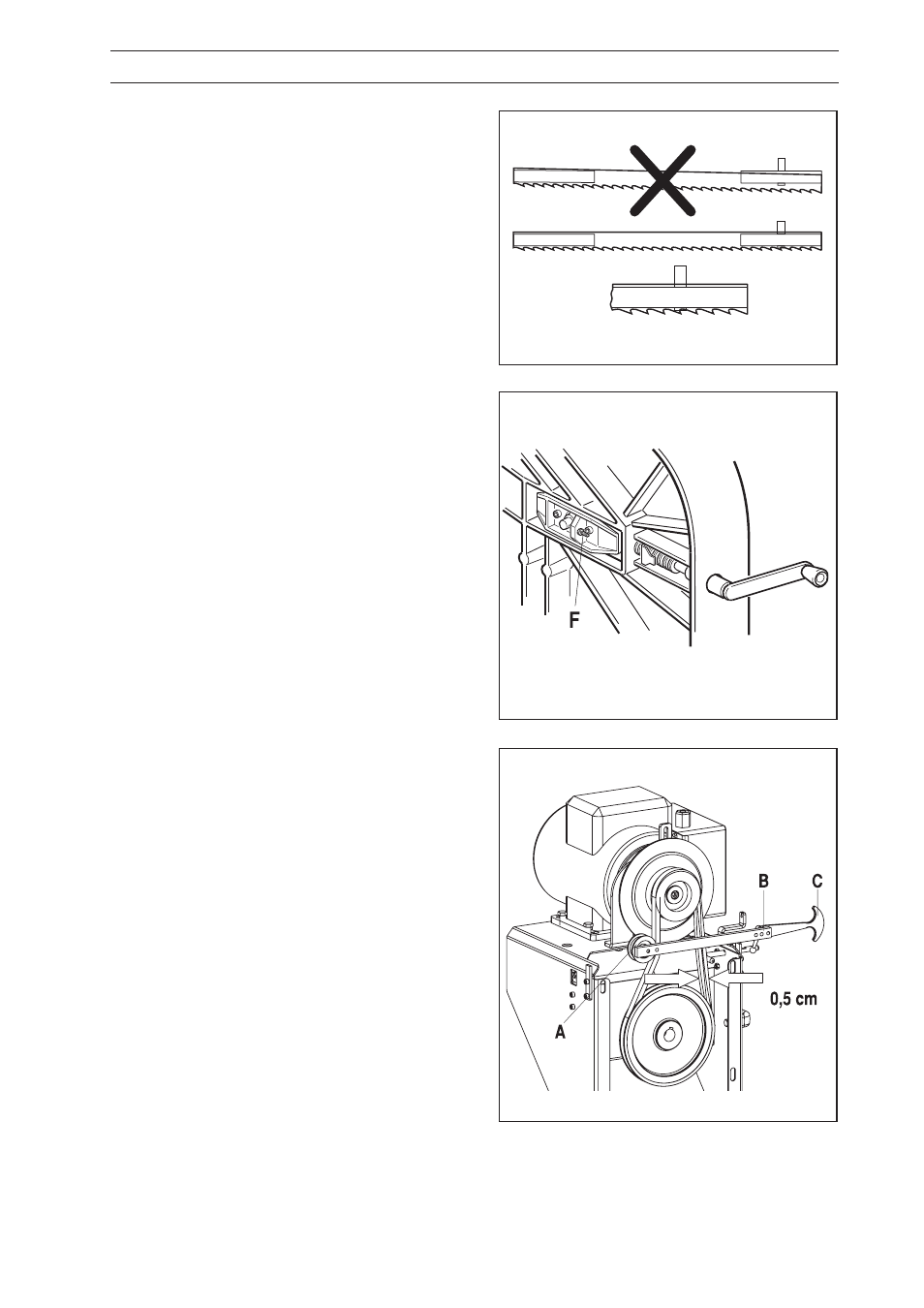

Band Wheel Adjustment

After the one-man saw has been used for a long

period, the band wheel bearings will start to wear

and change position. Meanwhile, the

foundation’s working geometry will have stabili-

sed. This means the parallelism of the band

wheels may need to be adjusted.

Adjustment is performed as follows:

1. Ensure that the electric power has been

disconnected. Unplug the electrical contact

or short-circuit the petrol engine.

2. Loosen the belt tension by releasing the idler

to the V-belt, so that the band wheel is free

and can be rotated by hand.

3. The bandsaw blade should be fitted and

adjusted.

4. Adjust the right-hand band wheel using the

screw (F). The screw is locked with a lock

nut, which should be loosened during

adjustment.

5. Check the alignment of the bandsaw blade

after adjustment by rotating the band wheel

by hand.

6. See FIG. 61 for the correct position.

7. If the bandsaw blade is not aligned, adjust

the right band wheel with the spacer located

on the outside of the band wheel. The wheel

is dismantled and the spacer is placed on the

innermost part of the wheel axle and the

wheel is then re-mounted. Repeat steps 2 to

5 until the bandsaw blade is aligned.

Drive Belt (FIG. 63)

The drive belt wears as the saw is used. The belt

should be replaced after 200 hours of operation

to avoid belt failure during operation. If the drive

slips or the belts need to be frequently adjusted,

this is a sign that the belts need to be replaced.

To replace the belt, proceed as follows:

1. Unplug the electrical contact from the distri-

bution box or short-circuit the petrol engine.

2. Loosen the belt guard.

3. Loosen the idler (A) completely with the

locking lever (B).

4. Change the belt and then tighten the belt by

pulling the handle (C) and tightening the idler

(A) and locking the idler with the locking lever

(B). When the belt is correctly tensioned, it

should be possible to move it about 0.5 cm in

each direction using one finger.

5. Attach the belt guard.

FIG. 63

FIG. 61

FIG. 62