Rabbeting, Chamfering edges, Safet y op era tion m aintenan c e setu p – Harbor Freight Tools 95838 User Manual

Page 12

Page 12

For technical questions, please call 1-800-444-3353.

Item 95838

SAFET

y

Op

ERA

TION

M

AINTENAN

c

E

SETU

p

Rabbeting

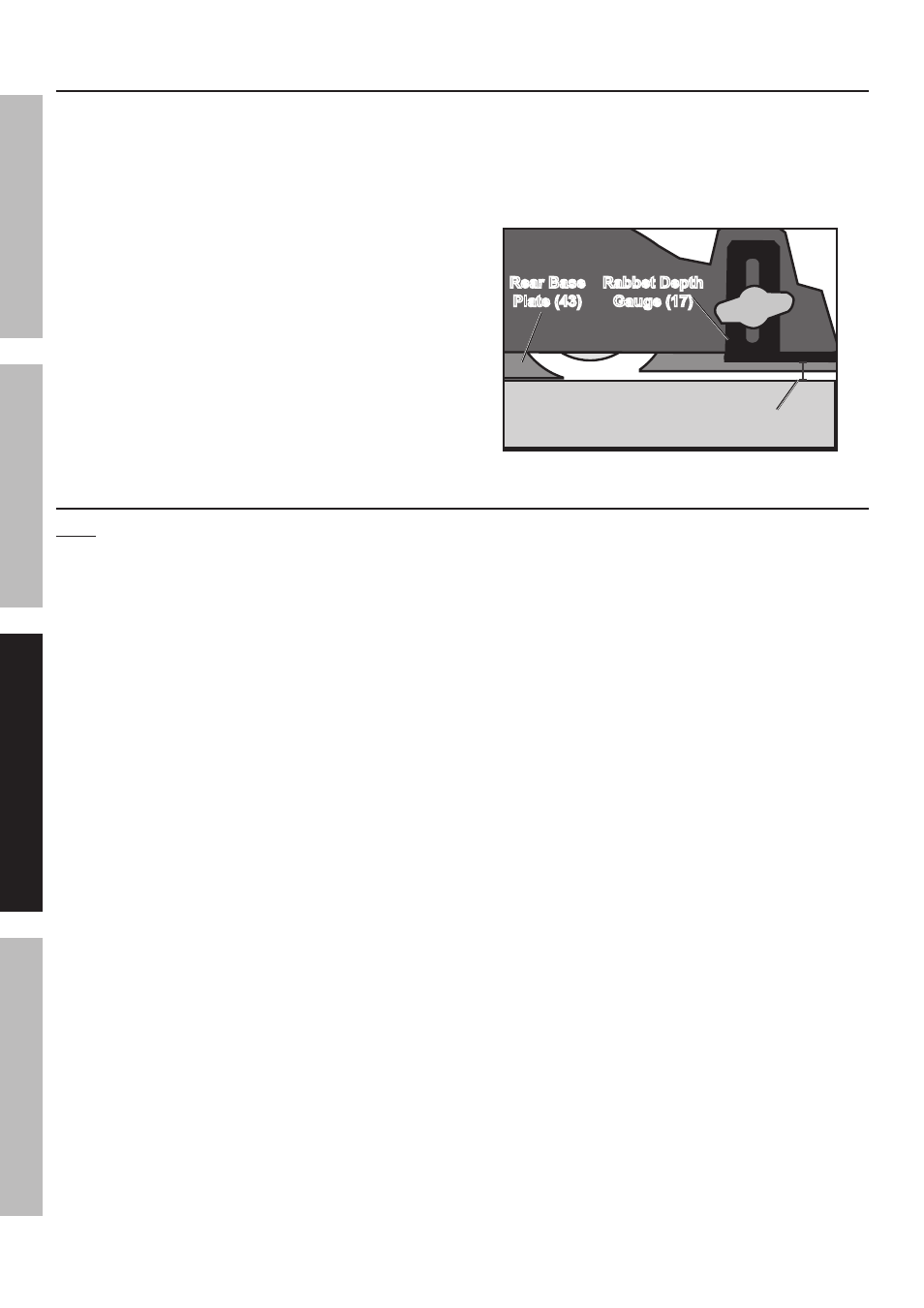

1. Rabbeting is creating a step on the edge of

a workpiece. Rabbeting is typically used in

door and window jambs. When rabbeting,

the Rabbet Depth Gauge (17) will contact the

unplaned portion of the workpiece and help

you avoid planing deeper than needed.

2. The Rabbet Depth Gauge needs to be carefully

set to the depth of the rabbet you wish to cut.

3. Using a straightedge (sold separately) adjust the

Rabbet Depth Gauge to the desired level from the

level of the Rear Base Plate (43) - see diagram above

and to the right. Maximum rabbet distance is

5

/

16

”

4. Set the Fence (37) to determine the

width of the rabbet you will cut.

5. Follow the instructions under thickness planing,

with the Rabbet Depth Gauge positioned over the

unplaned portion of the board. Plane the board

using multiple passes, if needed. The Rabbet Gauge

presses against the unplaned portion of the board

and helps the planer cut only to the specified depth.

Straightedge

(sold separately)

Rear Base

plate (43)

Rabbet Depth

Gauge (17)

Rabbet

Distance

chamfering Edges

Note: This technique takes requires experience to accomplish properly.

Practice on a piece of scrap wood before attempting to chamfer a workpiece.

1. This planer has a groove in the Adjustable

Base Plate (36) for cutting a 45° angle

along a corner, called a chamfer.

2. Place the groove on the corner edge that you wish to

cut a chamfer. The planer should be held at 45° and

the corner should be seated securely into the groove.

3. Follow the instructions under thickness planing.

Keep the corner securely seated in the groove

from the beginning all the way through the cut.