Displacement pump – Hitachi EM 490 User Manual

Page 17

307-735

17

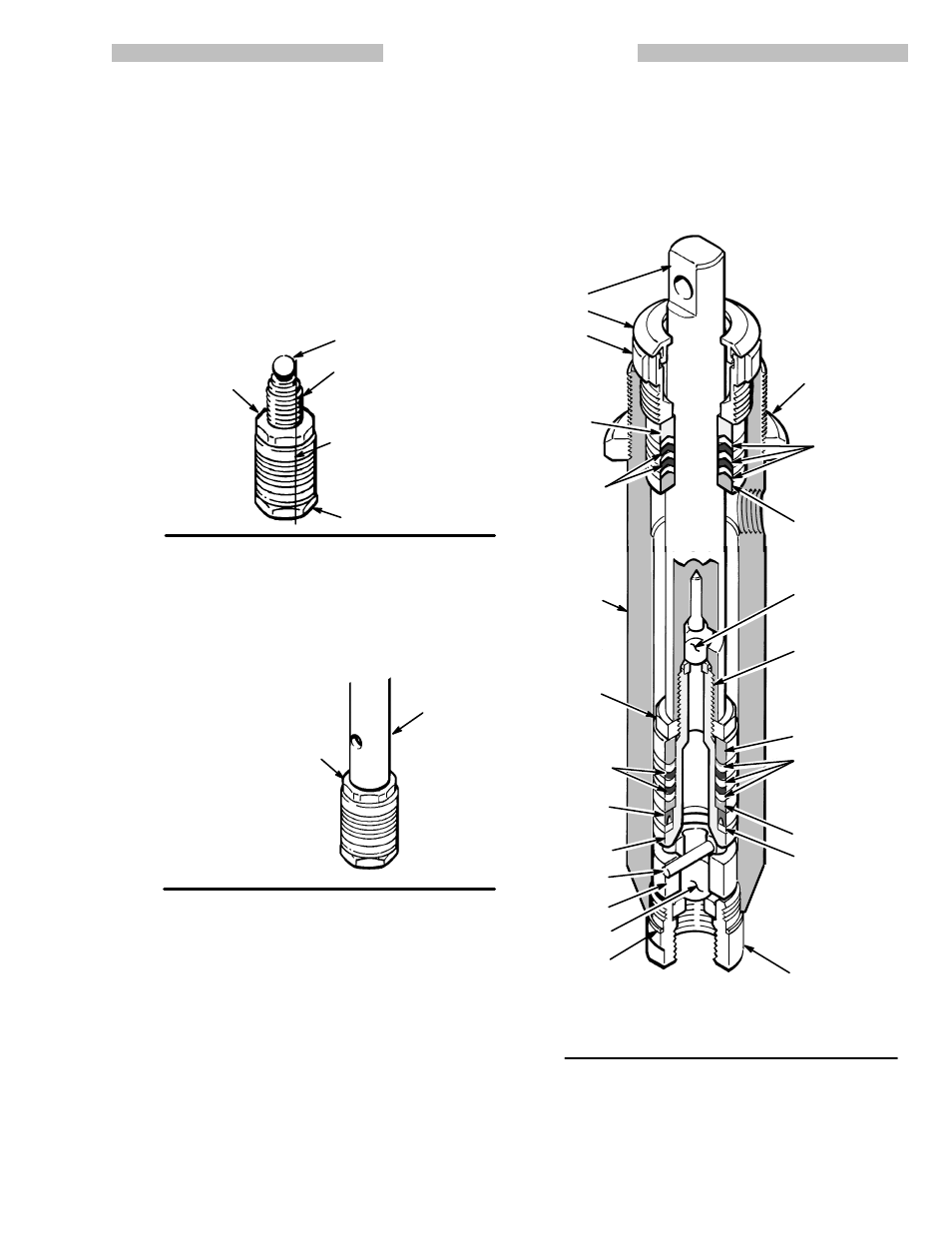

DISPLACEMENT PUMP

Reassembly Procedure

1.

Stack the backup washer (219*), U–cup seal (205*)

lips down, and female gland (220*), alternate the

polyethylene and leather v–packings (217*, 218*)

lips

up, and stack the male gland (213*) one at a time onto

the piston valve (224).

See Fig 15.

2.

Tighten the packing retaining nut (214) onto the piston

valve (224) and torque to 3–4 in–lb (0.34 – 0.35 N.m).

See Fig 13.

NOTE: NOTE THE ALIGNMENT of the piston (224) to

the nut (214). Maintain this alignment through-

out Steps 2, 3 and 4.

NOTE AND MAINTAIN

THIS ALIGNMENT

THROUGHOUT STEPS

3,4, AND 5

Fig 13

TORQUE NUT TO

3–4 IN-LB

(0.34–0.35 N.M)

APPLY ONE DROP

OF SEALANT TO

THESE THREADS

203*

224

214

3.

Apply

1 drop only of sealant, supplied with the repair

kit, to the piston valve threads. Place the small ball

(203*) on the valve. See Fig 13. Hand tighten the

valve into the rod (223) just until the nut contacts the

rod. Place the flats of the displacement rod in a vise.

Fig 14

214

TORQUE NUT AGAINST ROD

TO 19 FT-LB (25 N.M)

223

DO NOT ALLOW THIS NUT TO

MOVE RELATIVE TO THE

PISTON (224) WHEN

INSTALLING PISTON ONTO ROD

4.

Torque the nut (214) against the rod (223) to 19 ft–lb

(25 N.m). Use two wrenches to maintain the align-

ment as mentioned in the NOTE.

See Fig 14.

5.

Stack the male gland (211*), alternate the polyethyl-

ene and leather v–packings (218*, 209*)

lips down

and stack the female gland (212*) one at a time into

the top of the cylinder.

See Fig 15.

6.

Loosely install the packing nut (221) and plug (201).

7.

Insert the oiled piston rod (223) into the bottom of the

cylinder.

8.

Assemble the intake valve. Use a new gasket (206*).

Screw the valve into the cylinder and tighten to 80 ft–

lb (107 N.m).

See Fig 15.

9.

Screw down the cylinder locknut (112) until it is finger

tight at the bottom of the external cylinder threads.

See Fig 15.

10. Install the displacement pump on the sprayer. See

page 16.

Lips must face up

*208

216

APPLY 1 DROP

OF ADHESIVE

(in repair kit)

TO THESE

THREADS

Fig 15

201

223

*204

215

222

*206

*207

Lips must

face up

217*

Lips must

face down

218*

Lips must

face down

*209

224

Lips of seal

must face down

*205

203*

213*

220*

211*

*212

219*

TORQUE TO

80 ft–lb

(107 N.m)

221

112

214