EAW CB259 User Manual

Technical specifications cb259, Cinema systems

TECHNICAL SPECIFICATIONS CB259

CINEMA SYSTEMS

DESCRIPTIVE DATA continued

DESCRIPTIVE DATA

Powering Mode

Bi-amplified

System Crossover

(500 Hz minimum, 800 Hz

recommended, 24 dB/octave)

EAW CX300-CB259

Recommended High-Pass

Frequency (24 dB/Octave)

30 Hz

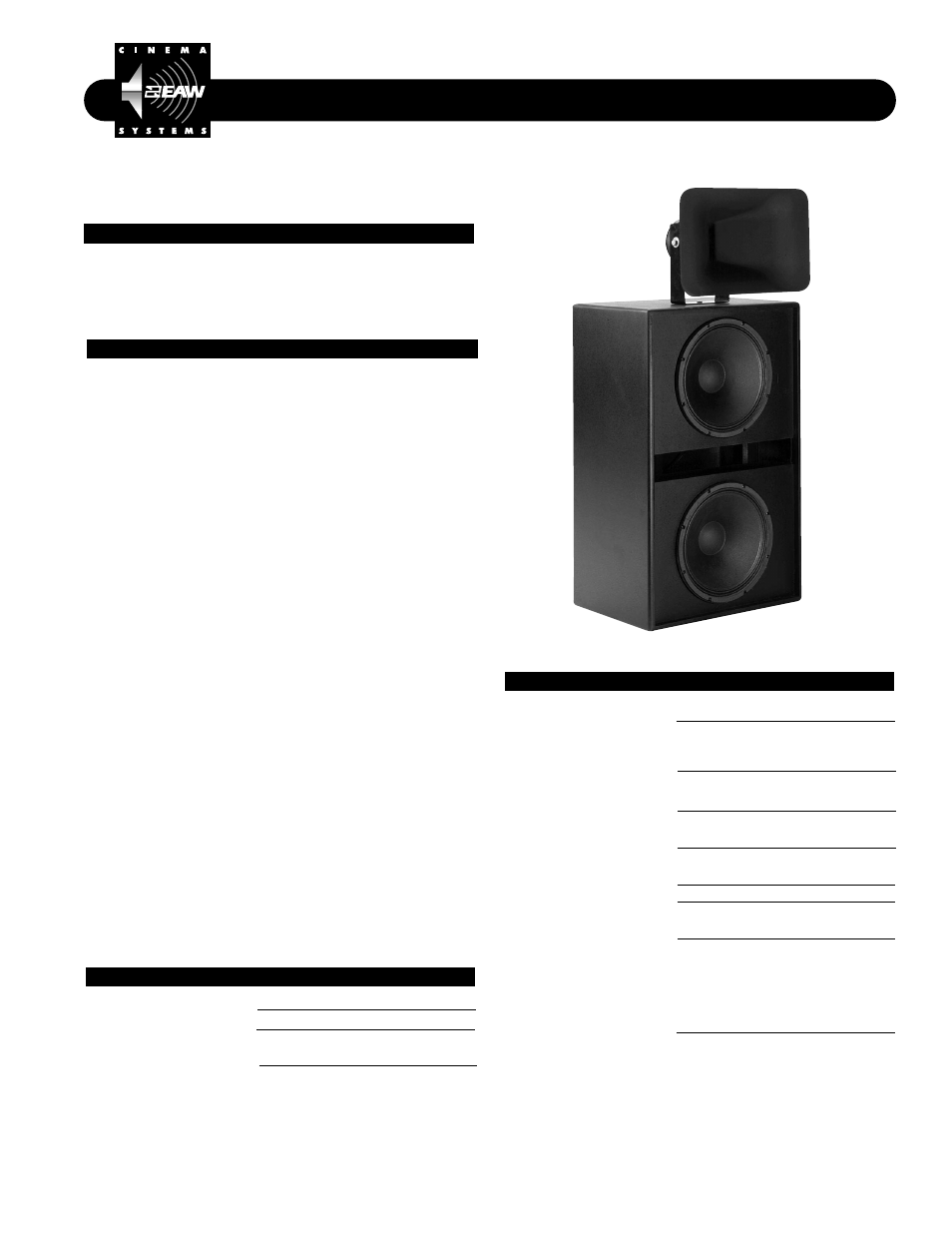

Cabinet Type (shape)

Rectangular (with externally mounted

horn/driver assembly

Enclosure Materials

3/4-in Medium Density Fiberboard

with 15 mm baltic birch baffle

Finish

Textured black

Connectors

LF-2 terminal barrier strip; HF-spring-

loaded pushbutton (accepts bare wire)

Dimensions

inches

millimeters

Height

54.19

1376

Width

24.44

621

Depth (min.)

17.75

633

Depth (max.)

24.94

633

Weights

pounds

kilograms

Net Weight

160.5

73.0

Shipping Weight

177.5

80.8

Part Number

999265

LF Subsystem & Loading

2x15-in vented

HF Subsystem & Loading

1x2-in exit compression driver on

CD horn

Configuration

2-way, Full Range

• For medium-sized theaters

• Bi-amplified 2-way screen channel loudspeaker

The CB259 high power, full range two-way screen loudspeaker system

fills medium-sized theaters with all the high-impact, full-range

sound encoded on today’s digital soundtracks while reproducing

voices clearly and naturally.

The two component system includes a BV253C vented dual 15-in low

frequency unit and a HK294 high frequency system - a medium for-

mat 90°x40° HF horn loading a large diaphragm 2-in exit compres-

sion driver.

The HK294’s constant directivity horn assures even distribution of

high frequency information to every seat in the house. Its shortened

horn throat minimizes horn throat distortion, eliminating the 700 Hz

“honk” that has plagued cinema HF horns.

The BV253C’s optimally vented enclosure uses the enclosure’s reso-

nance to increase LF response while limiting driver excursion. This

method produces less distortion and minimizes driver strain while

extending LF response to the lowest octaves.

The adjustable steel bracket attaching the HF horn to the LF enclo-

sure can be positioned at one of three mounting points for optimum

front/rear HF horn placement. The bracket allows the HF horn to be

aimed independently of the LF section in both the horizontal and

vertical planes and can be locked once it is positioned.

The LF section includes a two-terminal barrier strip that accommo-

dates bare wire, tinned leads or spade lugs. The Hf component uses

heavy duty spring-loaded push button type connectors. input con-

nectors for the LF section are located on the side of the enclosure

for convenient access in cramped installation areas. HF input con-

nectors are directly on the compression driver.

APPLICATION

PRODUCT INFORMATION