Enviro 828 DV.INS. User Manual

Page 5

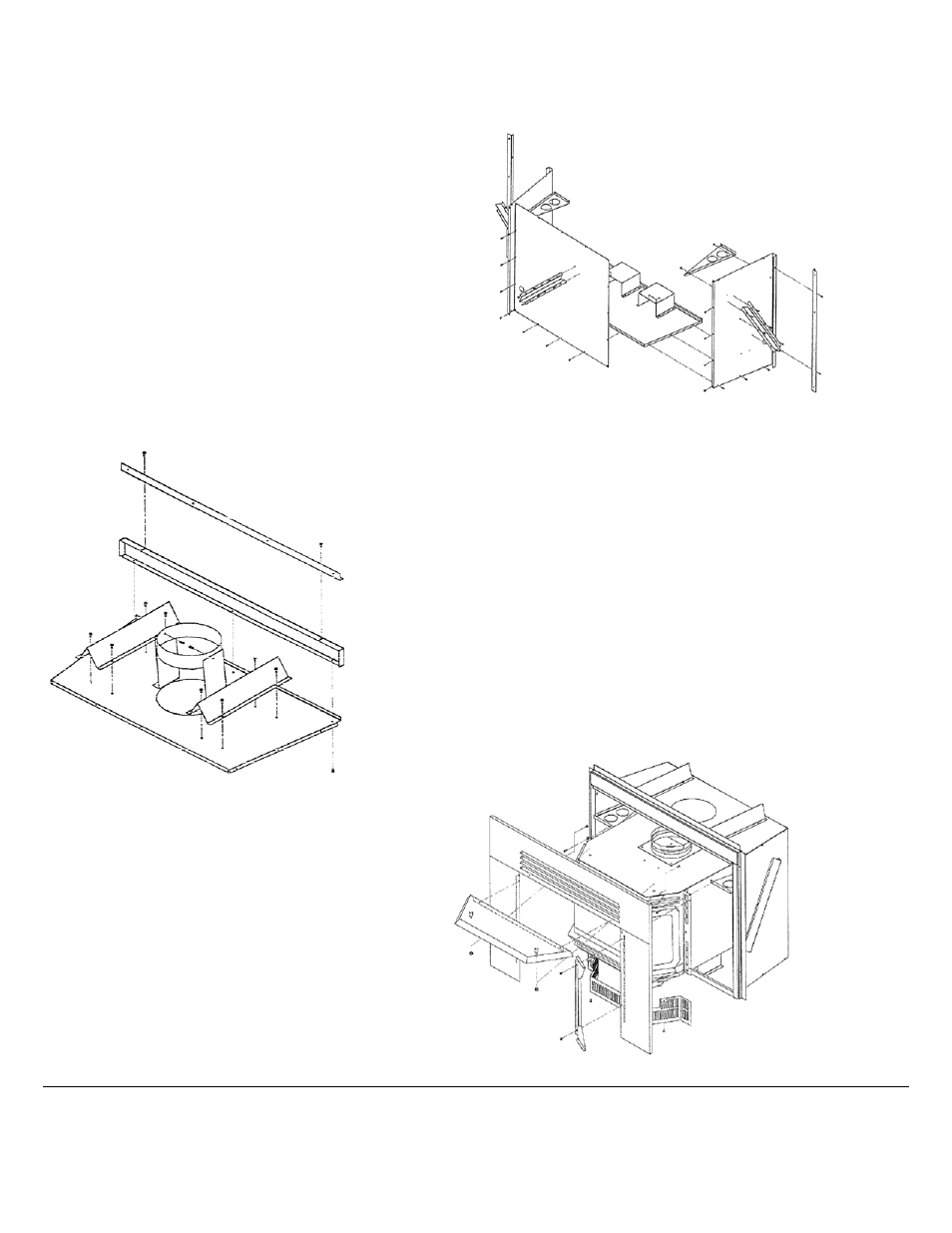

ZERO CLEARANCE BOX ASSEMBLY;

First take the kit from the box and place the surround panels aside so as not to damage the panels. There will also be a bag of screws, nuts

and bolts in the box. The bottom section of the kit will have two 3 inch square boxes mounted to the bottom. First attach the bottom to the

back with the screws provided, the hole should be located in the

lower right hand corner looking at it from the front. The side can then

be mounted to the bottom panel and the back panel. There are three

(3) vee shaped standoffs with six screw holes in each, and they

should be mounted on both sides as well as the back. There are also

two (2) triangular support brackets that must be fastened to the inside

of the box. There is a right hand and a left hand bracket, they should

be mounted with the flanges pointing upwards.

There are two long “L” shaped framing brackets that are screwed in

from the outside front edge of each side. Each bracket has three

adjustment holes depending on the thickness of the finished wall. The

hole that is furthest forward are for a wall thickness of 1/2” drywall

and the other holes are for other wall thickness up to 7/8” thick. The

Zero Clearance kit must be flush with the finished wall.

The next step is to put the top on the box. It will fit inside of the back

and side panels and is screwed in from the outside. The two short

vee shaped standoffs are screwed on to the top of the zero clearance kit. There are two large “L” type brackets that are to be screwed

down on either side of the hole were the flue pipe exits the box. These two brackets are to locate the clamping bracket that holds the

Simpson Duravent Telescoping pipe and allows the 828 unit to be disconnected and

removed if the unit needs to be repaired.

The next step is to attach the top extension to the Zero Clearance box. This is screwed

to the top front edge. The top framing bracket is in turn screwed to the top extension.

This top framing bracket has the same adjustment settings as the side framing

brackets.

Once the Zero Clearance box has been assembled it can be attached to the wall.

Place the unit into the framed opening and make sure the box is plumb and level.

The gas line then should be run through one of the three holes provided. The electrical

cord and conduit (if a fan is to be installed) should also be run into the box at this time.

The electrical box that is supplied with the fan kit will be mounted on the side, there

are two holes inside the Zero Clearance box for mounting.

The venting is the next step of installation. The pipe support on the top of the Zero

Clearance kit is made to hold the telescoping pipe section. The clamp should be

fastened 2” down from the top of the male end of the pipe.

This will allow the top of the pipe to be held in place while

the bottom section of pipe is attached to the stove.

The wall can now be finished with drywall and mantel if so

desired.

Installing the 828 direct vent insert. The unit can be lifted

up and put on the two support boxes on the bottom of the

box and then pushed back into the box. There are two

holes that must line up from the triangular supports inside

the Zero Clearance box to the holes on the inserts side

panel brackets and attached with the two screws provided.

The vent pipe should then be connected to the top of the

fireplace as well as the gas and electrical connections. The

vented skirt can now be mounted to the bottom of the unit

with the two 10 x 24 hex head screws provided, inserted

into. The surround panel can now be assembled and

bolted to the front of the stove.

5