Wiring – Empire Comfort Systems CHBR-16-3 User Manual

Page 16

Page 16

16934-3-0806

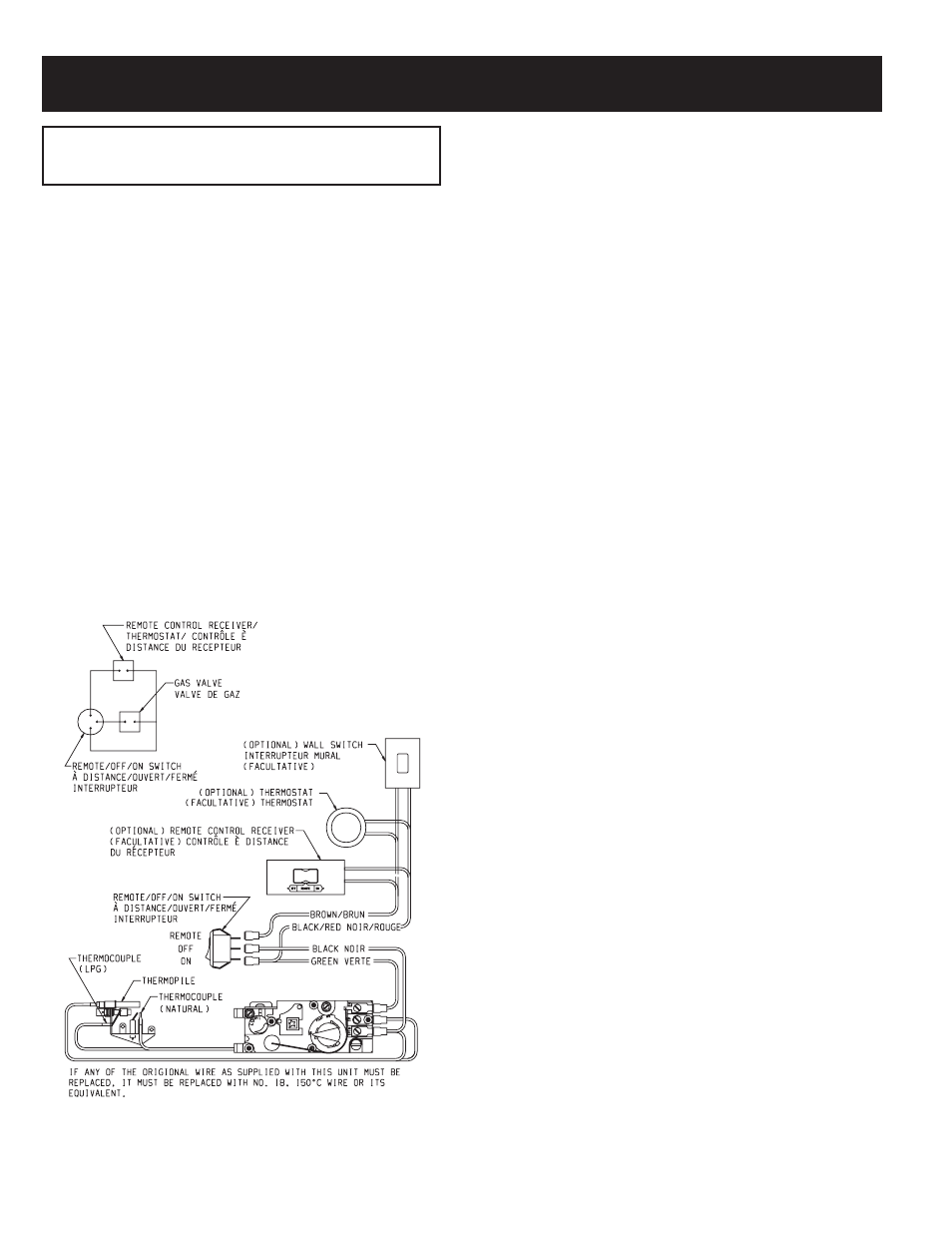

WIRING

Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing.

Control Panel Installation

1. Disconnect black and green wire from TH/TP and TH terminal

on valve.

2. Insert REMOTE/OFF/ON switch with attached wires through

rectangular opening on cover plate.

3. Attach black and green wire to TH/TP and TH terminal on

valve.

4. Attach cover plate to valve bracket with two (2) 8 x 1/2" Truss

-head Phillips screws.

Millivolt) thermopile is self powered gas valve and does not

require 110 volts. See Figure 10 to provide optional wall switch,

thermostat, or remote control. Maximum length of 20 feet of

16 AWG to conductor wires is to be used with all optional

switches.

Use the two leads (black/red wires and brown wires) from

REMOTE/ON/OFF switch to attach optional components.

Check System Operation

Millivolt system and all individual components may be checked

with a millivolt meter 0-1000 MV range.

Remote Receiver

Figure 10

1. The remote receiver can be placed behind the gas valve on

under side of chimenea.

2. Attach remote receiver to the flat bottom of casing behind gas

valve on underside of chimenea.

Refer to remote control installation and operating instructions for

more details on remote control.

750 Millivolt System

When you ignite the pilot, the thermocouple produces millivolts

(electrical current) which energizes the magnet in the gas valve.

After 30 seconds to 1 minute time period you can release the gas

control knob and the pilot will stay ON. Allow your pilot flame to

operate an additional one (1) to two (2) minutes before you turn the

gas control knob from the PILOT position to the ON position. This

time period allows the millivolts (electrical current) to buildup to

a sufficient level allowing the gas control to operate properly.

Millivolt Control

The valve regulator controls the burner pressure which should be

checked at the pressure test point. Turn captured screw counter

clockwise 2 or 3 turns and then place tubing to pressure gauge

over test point (Use test point “A” closest to control knob). After

taking pressure reading, be sure and turn captured screw clockwise

firmly to re-seal. Do not over torque. Check for gas leaks.