Ethernet communication module dvpen01-sl, 13 application of modbus tcp master – Delta DVPEN01-SL User Manual

Page 55

Ethernet Communication Module DVPEN01-SL

DVP-PLC Operation Manual

53

•

Write “0” into CR#28, and PLC_B will use CR#25 ~ CR#26 as the IP address of the destination

PLC.

•

Write the IP address of PLC_A into CR#25 and CR#26. The first two IP codes (192.168 =

H’C0A8) should be written into CR#26, and the last two IP codes (0.4 = H’0004) into CR#25.

•

Write the Modbus address of D0 (H’1000) in PLC_A into CR#81 and CR#84.

•

Write the Modbus address of D100 (register of RTC) (H’1064) into CR#86.

•

Write the number of registers K7 into CR#85.

•

Write “1” into CR#13 to start the data exchange.

•

CR#14 = 2 refers to successful execution. CR#14 = 3 refers to failed execution.

•

Once the data exchange is successful, the values in D1313 ~ D1318 in PLC_B will be written into

D0 ~ D6 of PLC_A.

6.13 Application of Modbus TCP Master

Application

Compiling Modbus instruction by PLC_B, making Y0 of PLC_A flashing

Network

requirement

(1) Adopt static IP.

(2) IP of PLC_A: 192.168.0.4

(3) IP of PLC_B: 192.168.0.5

(4) Update from PLC_B to PLC_A

(5) Use Modbus instruction 050500FF00 to set “On” Y0.

(6) Use Modbus instruction 0505000000 to set “Off” Y0.

(7) Y0 goes between On/Off once every one second.

1. See 6.1 for how to set up the communication.

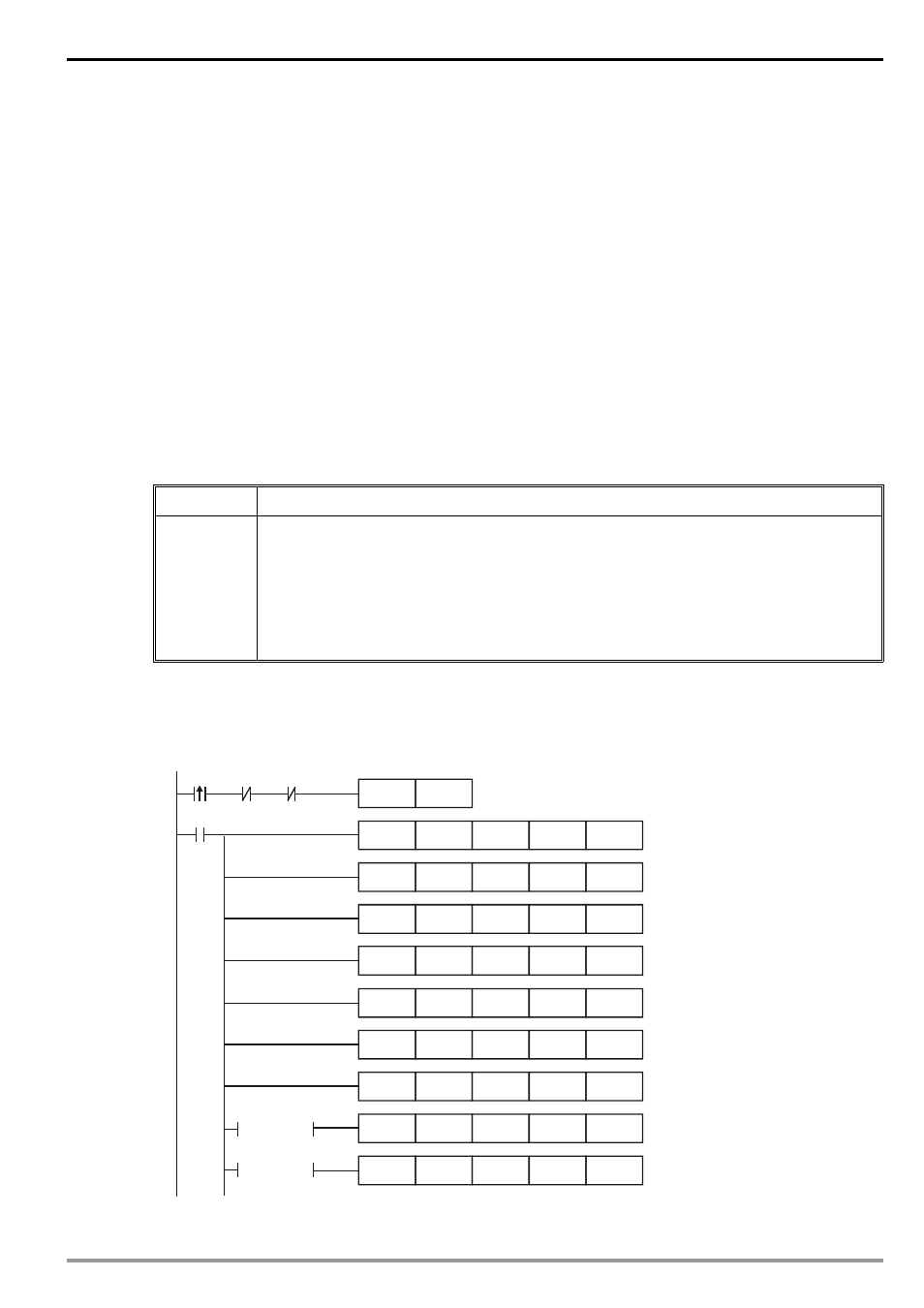

2. Compile the ladder diagram in the MPU and download it to PLC_B. See below for the program design.

We do not need to write any corresponding ladder diagram into PLC_A.

M1013

K100

K1

K100

K100

K1

M2

M1

M1

SET

M1

TOP

TOP

TOP

K100

TOP

K1

H4

HC0A8

K1

H0

K100

K100

K1

TOP

TOP

K100

TOP

K1

K1

K1

H0

H5

H5

K100

TOP

K1

K100

TOP

K1

H0

HFF

K118

K117

K111

K120

K121

K122

K123

K124

K124

= D0 K0

= D0 K1