Dremel 335 User Manual

Page 6

6

10.Press the release button to select the 1st

or 2nd routing depth (Fig. 9).

NOTE:

The adjustment of each routing

depth should be checked with a trial cut and

re-adjusted as necessary.

When routing is complete, loosen the hand

grip and return the router to the top position.

Feeding the Router

If the router is hard to control, heats up,

runs very slowly or leaves an imperfect cut,

consider these causes:

• Wrong direction of feed – hard to con-

trol.

• Feeding too fast – overloads motor.

• Dull bit – overloads motor.

• Cut too large for one pass – overloads

motor.

• Feeding too slow – leaves friction burns

on the workpiece.

Feed smoothly and steadily (do not force).

You will soon learn how the router sounds

and feels when it is working best.

Rate Of Feed

When routing or doing related work in wood

and plastics, the best finishes will result if

the depth of cut and feed rate are regulated

to keep the motor operating at high speed.

Feed the router at a moderate rate. Soft

materials require a faster feed rate than hard

materials.

The router may stall if improperly used or

overloaded. Reduce the feed rate to prevent

possible damage to the tool. Always be sure

the collet nut is tightened securely before

use. Always use router bits with the shortest

cutting length necessary to produce the

desired cut. This will minimize router bit run-

out and chatter.

Edge Forming

When edge forming, always use piloted or

bearing bits. The lower portion of a pilot

tipped bit is a shaft with no cutting edges.

Bearing guide bits have a ball bearing to

pilot the bit.

The pilot slides along the edge of the work

as the rotating blades make the cut, making

decorative edges. The edge on which the

pilot slides should be perfectly smooth since

any irregularities are transferred to the

shaped surface.

When routing a workpiece that requires edge

forming on the endgrain, always rout the

endgrain edge before routing the edges that

follow the grain. This minimizes the possibil-

ity of damage from any blowout at the end of

the endgrain.

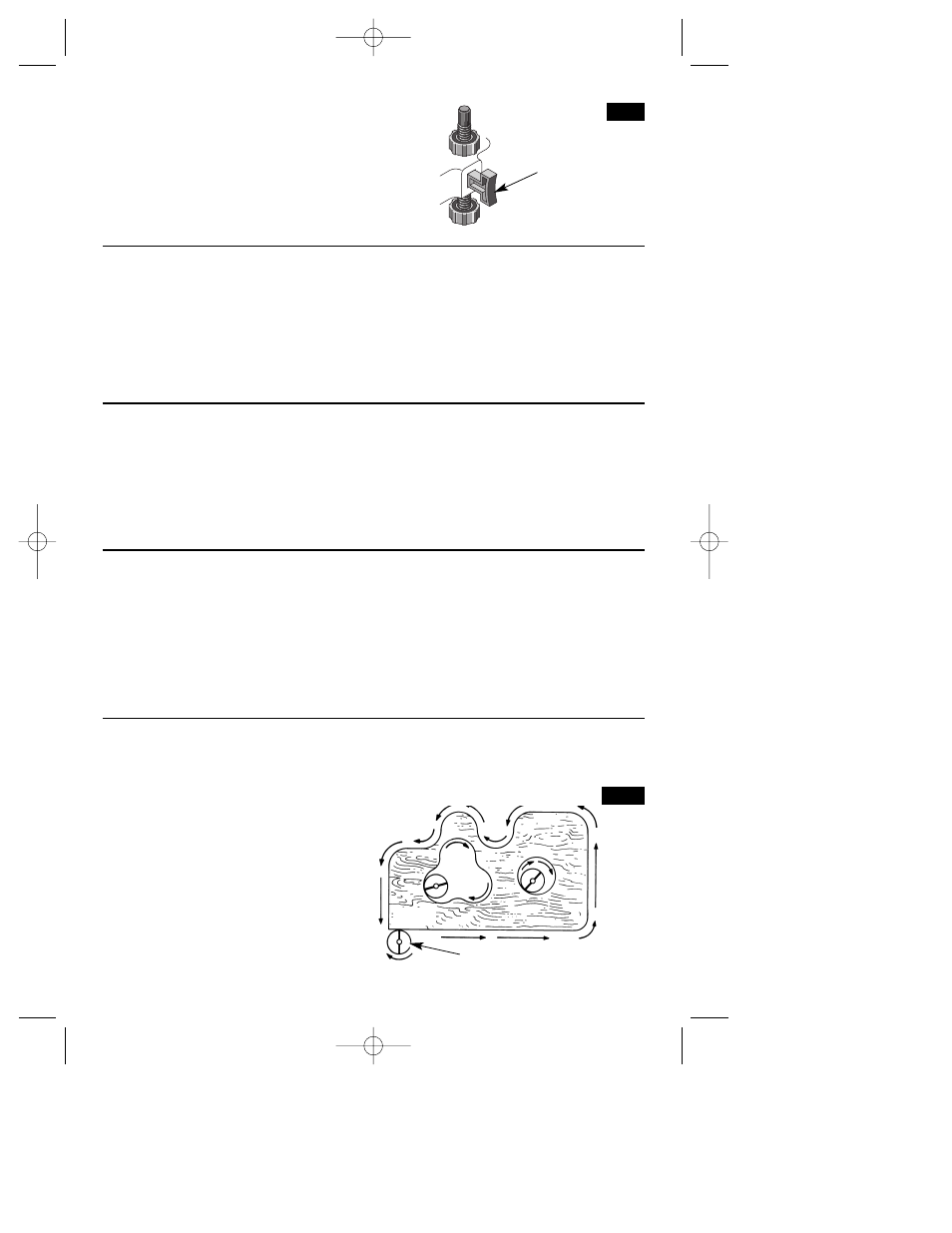

Router Feed Direction

The router spindle turns in a clockwise

direction when viewed from above. For best

control and quality of cut, feed the tool into

the workpiece in the direction that the bit will

tend to pull itself into the wood. Incorrect

feed direction will cause the bit to try and

climb over the wood.

Feed the tool in direction shown here. If cut-

ting around the edge of a square piece,

move the tool in a counterclockwise direc-

tion. If routing the inside surface as shown,

move in a clockwise direction (Fig. 10).

NOTE: Feed direction is extremely important

when using a pilot bit freehand on the edge

of a workpiece.

Release button

FIG. 9

Router Feed direction

Bit Rotation

Work

Rout

End

Grains

First

FIG. 10

DM 2610920458 2-04 2/19/04 12:24 PM Page 6