Installation – Desa SVYD18NRA/PRA SERIES User Manual

Page 13

www.desatech.com

113084-01A

13

INSTALLATION

Continued

CAUTION: Avoid damage to

regulator. Hold gas regulator

with wrench when connecting it

to gas piping and/or fittings.

* Purchase the optional CSA design-certified

equipment shutoff valve from your dealer. See

Accessories, page 27.

** Minimum inlet pressure for purpose of input

adjustment.

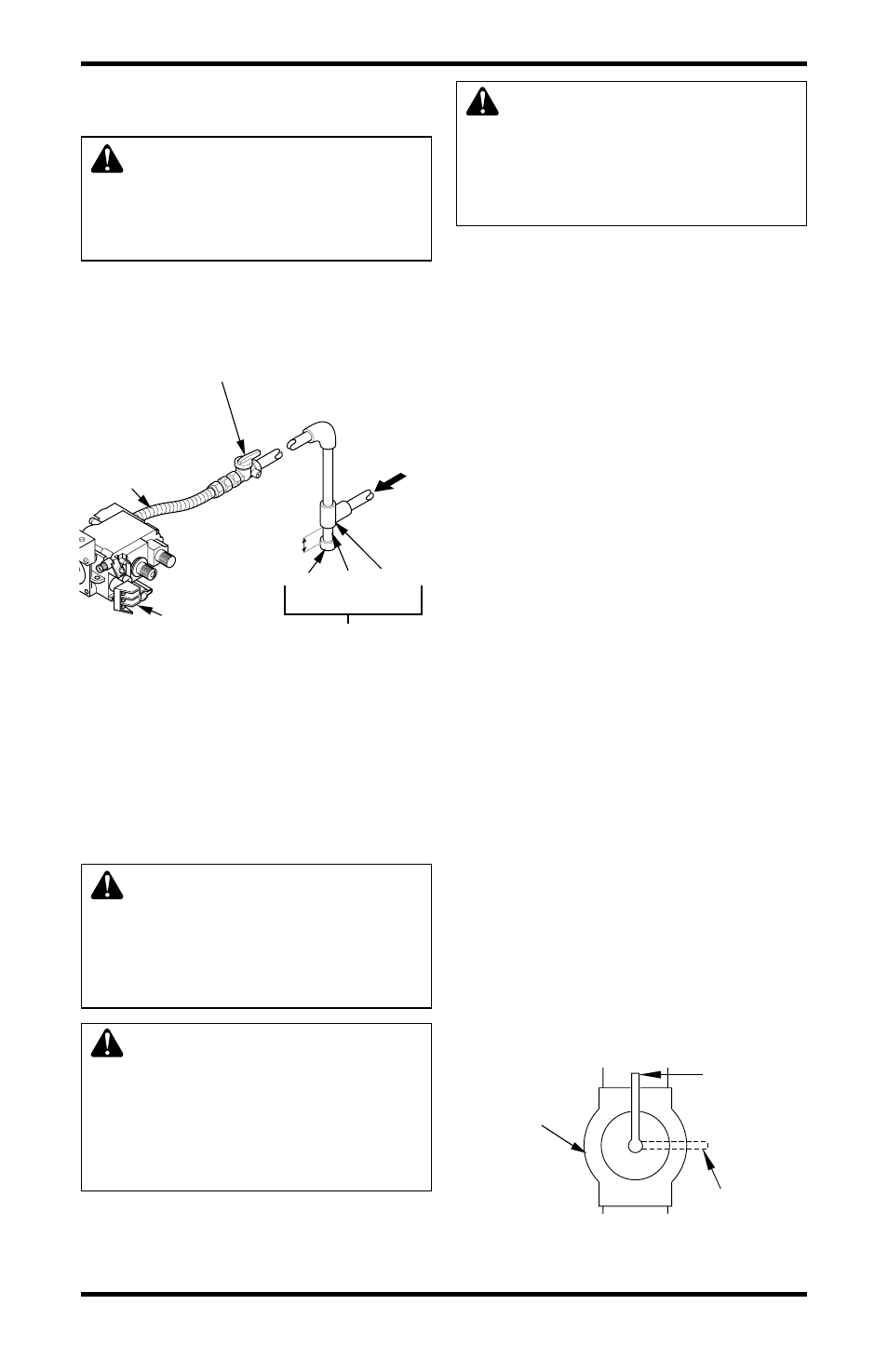

Figure 16 - Gas Connection

(SVYD18PRA/NRA Series)

3" Min

Sediment Trap

Gas Control

CSA Design-Certified

Equipment Shutoff Valve

With 1/8" NPT Tap*

Approved

Flexible Gas

Hose (if

allowed by

local codes)

Cap Pipe Tee

Nipple Joint

PROPANE/LP

From External

Regulator

(11" W.C. to 14"

W.C. Pressure)

NATURAL

From Gas

Meter (5" W.C.

to 10.5" W.C.

Pressure)

CHECKING GAS CONNECTIONS

WARNING: Test all gas pip-

ing and connections, internal

and external to unit, for leaks

after installing or servicing. Cor-

rect all leaks at once.

WARNING: Never use an

open flame to check for a leak.

Apply a noncorrosive leak de-

tection fluid to all joints. Bubbles

forming show a leak. Correct all

leaks at once.

CAUTION: Make sure exter-

nal regulator has been installed

between propane/LP supply and

heater. See guidelines under

Con-

necting to Gas Supply, page 11.

Pressure Testing Gas Supply Piping

System

Test Pressures In Excess Of 1/2 PSIG (3.5 kPa)

1.

Disconnect appliance with its appliance main

gas valve (control valve) and equipment

shutoff valve from gas supply piping system.

Pressures in excess of 1/2 psig will damage

heater regulator.

2.

Cap off open end of gas pipe where equip-

ment shutoff valve was connected.

3.

Pressurize supply piping system by either

opening propane/LP supply tank valve for

propane/LP gas or opening main gas valve lo-

cated on or near gas meter for natural gas, or

using compressed air.

4.

Check all joints of gas supply piping system.

Apply a noncorrosive leak detection fluid to

gas joints. Bubbles forming show a leak.

5.

Correct all leaks at once.

6.

Reconnect heater and equipment shutoff valve

to gas supply. Check reconnected fittings for

leaks.

Test Pressures Equal To or Less Than 1/2 PSIG

(3.5 kPa)

1.

Close equipment shutoff valve (see Figure 17).

2.

Pressurize supply piping system by either

opening propane/LP supply tank valve for

propane/LP gas or opening main gas valve lo-

cated on or near gas meter for natural gas, or

using compressed air.

3.

Check all joints from gas meter for natural or

propane/LP supply to equipment shutoff valve

(see Figure 18 or 19, page 14). Apply a non-

corrosive leak detection fluid to gas joints.

Bubbles forming show a leak.

4.

Correct all leaks at once.

Figure 17 - Equipment Shutoff Valve

Equipment

Shutoff Valve

ON

POSIT

O

POS

Closed

Open