DVS -30-2 User Manual

Page 11

13369-1-0203

Page 11

Attention: When fireplace is installed in optional full cabinet

mantel or corner mantel the (4) four nailing flanges shown in

Figure 11 will not be installed on the side of outer casing. The DVS

will be attached to the full cabinet mantel or corner mantel with the

(2) two nailing flanges located on the top of the outer casing

assembly.

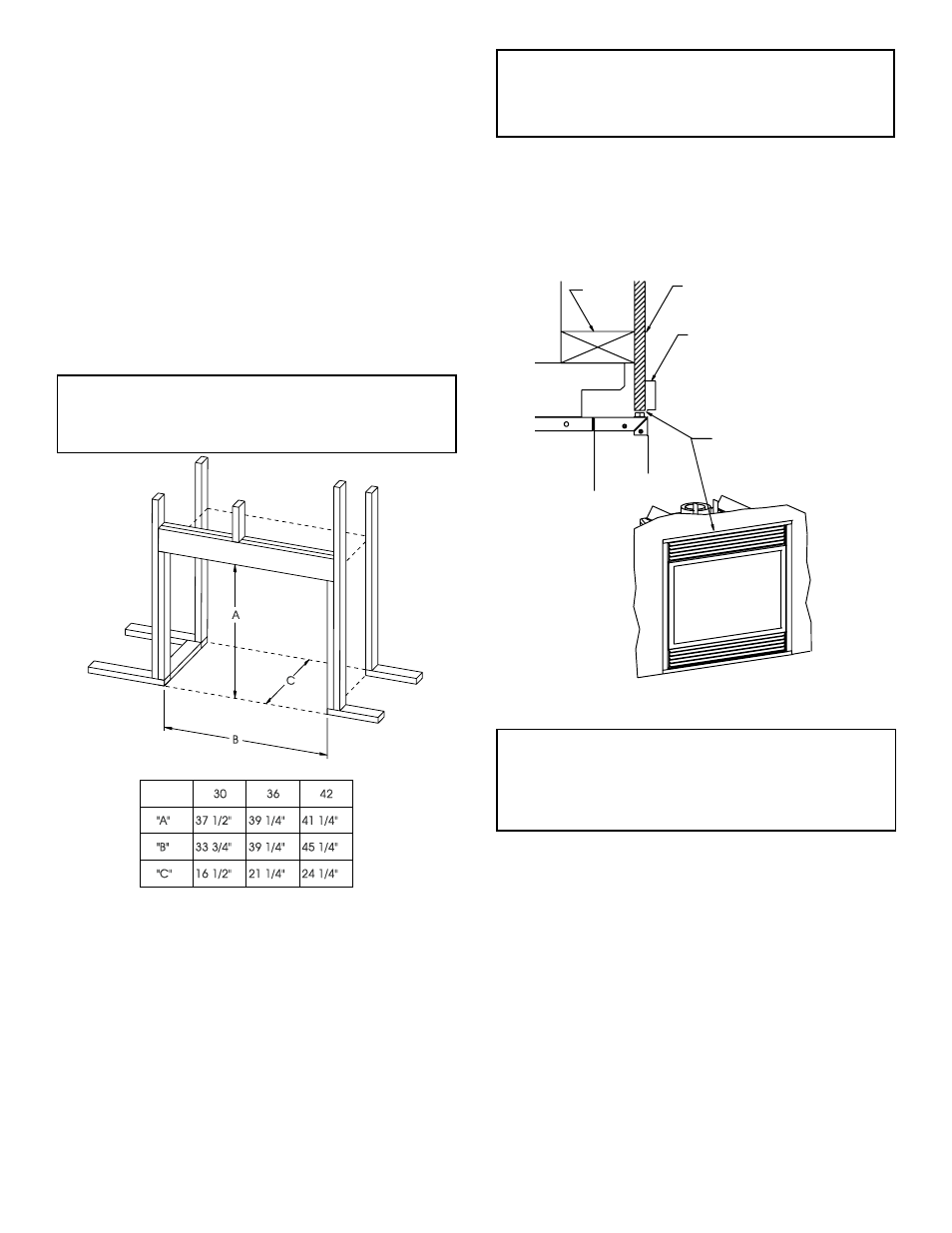

Framing (Figure 12)

Fireplace framing can be built before or after the fireplace is set in

place. Framing should be positioned to accommodate wall covering

and fireplace facing material. The fireplace framing should

constructed of 2 x 4 lumber or heavier. The framing headers may

rest on the fireplace standoffs. Refer to Figure 12 for framing

reference dimensions.

CAUTION: MEASURE FIREPLACE DIMENSIONS AND

VERIFY FRAMING METHODS, AND WALL COVERING

DETAILS BEFORE FRAMING CONSTRUCTION BEGINS.

Framing dimension A includes a three inch clearance for

standoffs on firebox. After installing firebox into framing,

the finished wall surface must cover the three inch opening

above the firebox.

Figure 12

Attention: If a base or mantel is not used and the appliance is

installed directly on carpeting, tile or other combustible material

other than wood flooring, it shall be installed on a metal or wood

panel extending the full width and depth of the appliance. The

vertical dimension in Figure 12 must be adjusted when a metal or

wood panel is placed beneath the appliance.

Finishing (Figure 13)

Finish the walls with the material of your choice. Figure 6 shows

the minimum vertical and corresponding maximum horizontal

dimensions of mantels or other combustible projections above the

top front edge of the fireplace.

Only non-combustible materials may be used to cover the black

fireplace front.

WARNING: When finishing the fireplace never obstruct

or modify the air inlet/outlet louvers in any manner.

Provide adequate clearances around air openings into the

combustion chamber.

Caution: If the joints between the finished wall and the

fireplace surround (top and sides) are sealed, a 300

°

F mini-

mum sealant material must be used. These joints are not

required to be sealed. Only non-combustible material (using

300

°

F minimum adhesive if needed), can be applied as facing

to the fireplace surround.

FINISHED WALL

FINISHED WALL

2 X 4

2 X 4

HEADER

STAND OFF

STAND OFF

FRONT TRIM OR

FRONT TRIM OR

NON-COMBUSTIBLE MATERIAL

NON-COMBUSTIBLE MATERIAL

(INSTALLATION IS OPTIONAL)

(INSTALLATION IS OPTIONAL)

JOINT BETWEEN FINISHED

JOINT BETWEEN FINISHED

WALL AND UNIT SEALED

WALL AND UNIT SEALED

WITH 300°F, 149°C SEALANT

WITH 300°F, 149°C SEALANT

MATERIAL

Figure 13

Attention:

Cold climate installation recommendation: When installing

this unit against a non-insulated exterior wall, it is mandatory

that the outer walls be insulated to conform to applicable

insulation codes.

Vent Runs (Figures 14, 15, 16, 17 and 18)

In planning the installation for the fireplace, it is necessary to

install certain components before the appliance is completely

positioned and installed. These include the direct vent system, gas

piping for the appliance and the electrical wiring. (If the fan

option is used.)

The appliance can be mounted on any of the following surfaces:

1. A flat, hard combustible (burnable) surface.

2. A raised wooden platform.

3. Four (4) corner supports. (Example: Four (4) concrete masonry

blocks.) These supports must be positioned so they contact all

four (4) perimeter edges on the bottom of the unit.

Three (3) basic types of installations

1. Straight out (4" - 8" wall thickness).

2. Extended straight out (8" - 36" wall thickness).

3. Vertical installations.