Reference calculations, Legend, Unit startup – WaterFurnace Series NXW User Manual

Page 28: Verify the following, Startup steps

28

ENVISION

2

NKW 50Hz REVERSIBLE CHILLER INSTALLATION MANUAL

Reference Calculations

Verify the following:

• High voltage is correct and matches nameplate

• Fuses, breakers and wire size are correct

• Low voltage wiring is complete

• Piping is complete and the water system has been cleaned

and flushed

• Air is purged from closed loop system

• Isolation valves are open and water control valves or loop

pumps are wired

• Service/access panels are in place

• Transformer has been switched to lower voltage tap if

needed (380/420 volt units only)

• Unit controls are in “off” position

• Flow switches are installed and ready or wires are jumpered

• Freeze detection setpoints have been set in the

microprocessor

WARNING: Verify ALL water controls are open and

allow water flow PRIOR to engaging the compressor.

Failure to do so can result in freezing the heat

exchanger or water lines causing permanent damage

to the unit.

Unit Startup

Startup Steps

• Set aquastat control above cooling setpoint.

• Set aquastat control in cooling mode.

• Slowly reduce the control setting until both the compressor

and water control valve/loop pumps are activated. Verify

that the compressor is on and that the water flow rate

is correct by measuring pressure drop through the heat

exchanger and comparing to the Pressure Drop table (page

32). Check for correct rotation of scroll compressors. Switch

any two power leads at the L1, L2, and L3 line voltage

termination block if incorrect.

• Perform a cooling capacity test by multiplying L/S x T x 4.1

(antifreeze/water). Use 4.2 for 100% water. Check capacity

against catalog data at same conditions.

• Set control to “OFF” position.

• Leave unit “OFF” for approximately five (5) minutes to allow

pressure to equalize.

• Adjust control below heating setpoint.

• Set control in “HEAT” position mode.

• Slowly increase the control setting until both compressor

and water control valve/loop pumps are activated. The

reversing valve should be heard changing over.

• Perform a heating capacity test by multiplying L/S x T x 4.1

(antifreeze/water). Use 4.2 for 100% water. Check capacity

against catalog data at same conditions.

• Check for vibrations, noise and water leaks.

• Set system to maintain desired setpoint.

• Instruct the owner/operator of correct control and system

operation.

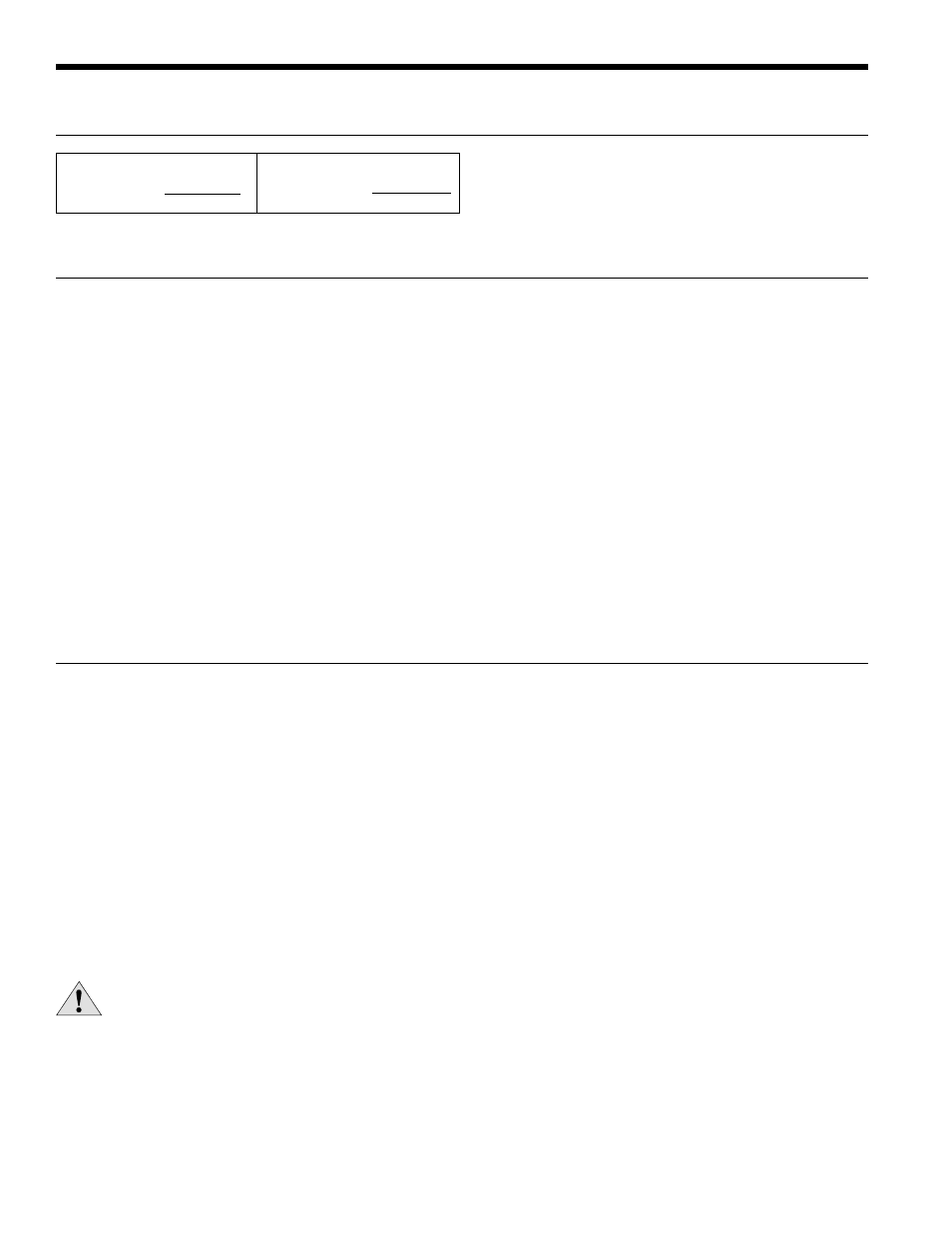

HE

L/S x 4.2*

Heating Calculations:

Cooling Calculations:

LWT = EWT +

HR

L/S x 4.2*

LWT = EWT -

NOTE: * When using water. Use 4.1 for 15% methanol/water or Environol solution.

Legend

ABBREVIATIONS AND DEFINITIONS:

COP

= coefficient of performance

EER

= cooling energy efficiency (TC/kW)

ELT

= entering load fluid temperature

EST

= entering source fluid temperature to heat pump

FLA

= full load amps

FtHd = pressure drop in feet of head

gpm

= US gallon per minute

HC

= heating capacity in kW

HE

= heat of extraction in kW

HR

= heat rejected in kW

kPa =

kilopascal

kW =

kilowatt

L/s

= liters per second

LLT

= leaving load fluid temperature from heat pump

LRA

= locked rotor amps (starting current)

LST

= leaving source fluid temperature from heat pump

LWPD = load heat exchanger water pressure drop

MCC = maximum continuous current

PD =

pressure

drop

psi

= pressure drop in pounds per square inch

P/T =

Pressure/Temperature

RLA

= run load amps

TC

= total cooling capacity in kW

W =

Watt

CONVERSIONS:

x°F =

(x - 32)/1.8°C

1 bar

= 100 kPa

1 gpm = 0.0631 L/s

1 US Gallon

= 3.785412 L

1 Btu/h

= 0.29037 W