Controls - aurora base control cont, Aurora interface and diagnostics (aid) tool, Aurora – WaterFurnace Versatec Base User Manual

Page 31: Base control, Versatec base series 50hz installation manual, Status led (led3, green), Configuration led (led2, yellow), Fault led (led1, red)

31

VERSATEC BASE SERIES 50Hz INSTALLATION MANUAL

CC2

Factory

Fault

ALG

ALM

LS

ES

ACC c

Status

Aurora

TM

Base

Control

RV – K1

CC2

CC – K2

CC Hi – K3

Fan – K4

Alarm – K5

Acc – K6

ACC no

ACC nc

O/B

C

R

LO

G

Y1

Y2

W

DH

3A-Fuse

O/B

C

R

LO

G

Y1

Y2

W

DH

LO

G

HI

CCG

CC

FG

F

R

HP

HP

LP

FP2

FP2

FP1

REV

REV

CFM

PWM

ECM PWM

Factory

Factory Fan Connection

R

R

CC

C

C

R

(-)

(+)

RS 485

EH2

C

EH1

C

CO

(+)

(-)

R

C

RS485

Exp

Factory

Com1

Com2

Config

G

G

G

Y

R

SW1 Test

FP1 – 15

o

F/30

o

F

JW2 - Alarm

P11

P5

P2

P1

P8

P7

P9

P6

P3

SW2

P13

P4

FP2 – 15

o

F/30

o

F

RV – B/O

ACC – Dip 1

ACC – Dip 2

CC – Dual/Single

L – Pulse/Continuous

Reheat/Normal

Factory Use

Field Connections

Field Connections

C

LP

FP1

F

CC

G

Y1

1

2

3

4

5

6

7

8

Off

On

N/A

RS485 NET

EH1

LED 1

LED 3

LED 2

LED 5

LED 4

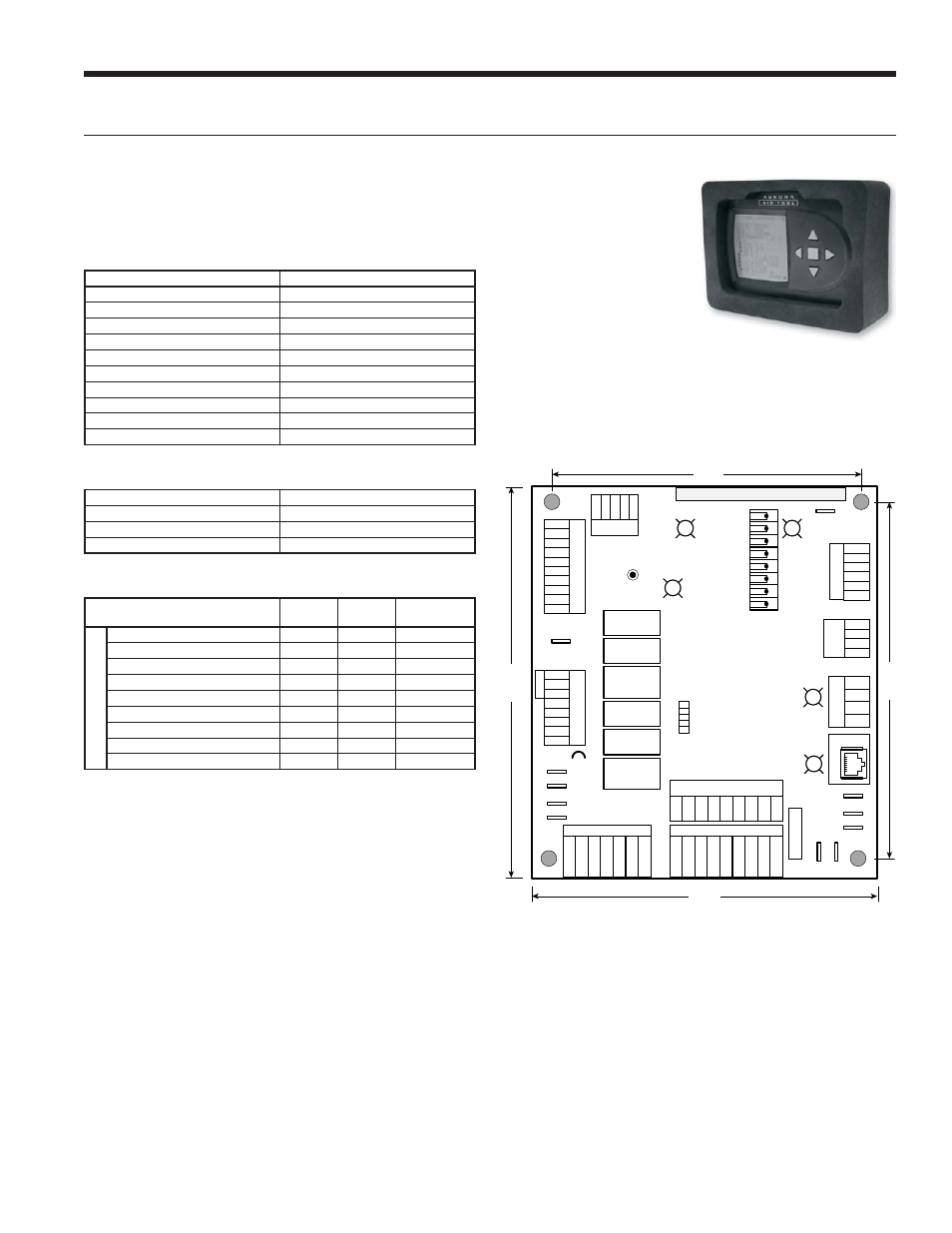

12.7 cm

15.9 cm

14.0 cm

14.6 cm

Aurora Interface and Diagnostics (AID) Tool

The Aurora Interface and

Diagnostics (AID) Tool is

a device that is a member

of the Aurora network.

The AID Tool is used to

troubleshoot equipment

which uses the Aurora

control via Modbus RTU

communication. The AID

Tool provides diagnostics,

fault management, ECM

setup, and system configuration capabilities to the Aurora

family of controls. An AID Tool is recommended, although

not required, for ECM airflow settings. The AID Tool simply

plugs into the exterior of the cabinet in the AID Tool port.

ABC Control Board Layout

Aurora ‘Base’ Control LED Displays

These three LEDs display the status, configuration, and

fault codes for the control. These can also be read in plain

English via the Aurora AID Tool.

Status LED (LED3, Green)

Description of Operation

Fault LED, Green

Normal Mode

ON

Control is Non-functional

OFF

Test Mode

Slow Flash

Lockout Active

Fast Flash

Dehumidification Mode

Flash Code 2

(Future Use)

Flash Code 3

(Future Use)

Flash Code 4

Load Shed

Flash Code 5

ESD

Flash Code 6

(Future Use)

Flash Code 7

Configuration LED (LED2, Yellow)

Description of Operation

Configuration LED, Yellow

No Software Overwritten

Flashing ECM Setting

DIP Switch was Overwritten

Slow Flash

ECM Configuration Mode

Fast Flash

Fault LED (LED1, Red)

Red Fault LED

LED Flash

Code*

Lockout

Reset/

Remove

ABC Basic F

aults

Normal - No Faults

OFF

–

Fault - Input

1

No

Auto

Fault - High Pressure

2

Yes

Hard or Soft

Fault - Low Pressure

3

Yes

Hard or Soft

Fault - Freeze Detection FP2

4

Yes

Hard or Soft

Fault - Freeze Detection FP1

5

Yes

Hard or Soft

Fault - Condensate Overflow

7

Yes

Hard or Soft

Fault - Over/Under Voltage

8

No

Auto

Fault - FP1 & FP2 Sensor Error

11

Yes

Hard or Soft

NOTE: All codes >11 use long flash for tens digit and short flash for the ones

digit. 20, 30, 40, 50, etc. are skipped.

Controls - Aurora Base Control cont.