How to use the vessel, Fixed head vessels, Moveable head vessels – Parr Instrument 4575/76 HP/HT User Manual

Page 12: To open the vessel, Before closing the vessel, To close the vessel, Gas connections, Pressurizing the vessel

P a r r I n s t r u m e n t C o m p a n y

4575/76 HP/HT Pressure Reactors

12

How to Use the Vessel

Fixed Head Vessels

First, lower the heater and push it to the side. Be-

fore attempting to remove the split ring open the

gas release valve to discharge any internal pressure.

Raise the cylinder support holder to the bottom of

the cylinder. The head with any attached connection

lines will remain in place.

Moveable Head Vessels

First, open the gas release valve to discharge any

internal pressure. Remove the complete vessel as-

sembly from the support stand.

To open the Vessel

Loosen the bolts in a criss-cross pattern reversing

the tightening procedure, gradually decreasing the

torque on each bolt. The head assembly can be re-

moved from the cylinder. Handle the head carefully

so that no damage will occur to any of the internal

fittings.

Before closing the Vessel

Examine the head seal carefully to be sure that it

is in good condition. The seal should not have any

nicks, be hardened or deformed. Also examine the

mating surfaces on the head and cylinder to be sure

they are clean and free from burrs.

To Close the Vessel

Place the two split ring halves around the head and

cylinder flanges. Close the latches on the fixed head

split ring. Install the drop band on the movable

head split ring.

A torque wrench is furnished with these vessels

and it includes an adapter for the 12 point heads of

the bolts used in these split rings. The amount of

torque to be applied will depend upon the intended

maximum operating pressure. To ensure a good

seal over the full operating range apply the recom-

mended bolt torque per the table below.

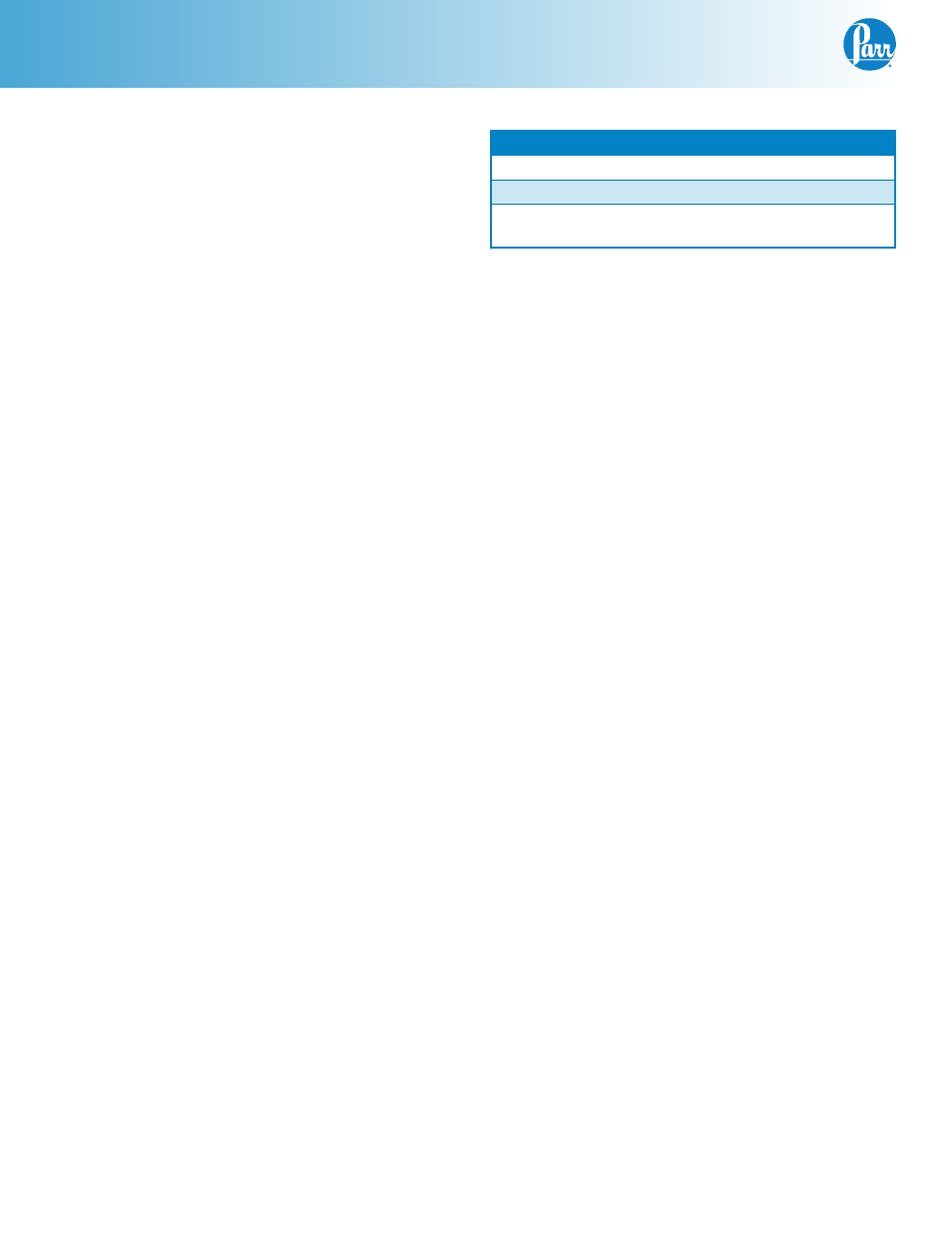

Recommended Bolt Torque

Material

Pressure (psi) Torque (ft-lb)

PTFE

0 - 3000

35 ft-lbs

Flexible Graphite

0 - 3000

35 ft-lbs

PTFE or Flexible

Graphite

4000 - 5000

40 ft-lbs

Pick a starting bolt and tighten it to approximately

15 ft-lbs. Then by-pass the adjacent bolts and move

around the closure to a bolt approximately 180 de-

grees from the starting bolt. Torque all bolts to the

initial 15 ft-lbs. Then proceed with the same pattern

increasing the torque in 10 ft-lbs increments.

Note:

Flexible graphite gaskets tend to be

somewhat flakey. To extend the useful life

of these gaskets, first rough up the sealing

surface of the cylinder with 120 grit sand pa-

per to ensure the gasket remains in the head

groove and does not stick to the cylinder.

Secondly, coat both sealing surfaces with

a silicone lubricant. This process will aid in

compressing the gasket so it does not break

apart after one use.

Gas Connections

Gas connections are dependent on applications.

For most applications the stainless steel hose fur-

nished with the system is sufficient. Attach the Type

“A” coned pressure fitting into the adapter attached

to the gas inlet valve and tighten the compres-

sion nut firmly. Do not use any thread dope on the

coned fitting.

Pressurizing the Vessel

Check all valves carefully before admitting gas into

the system. The liquid sampling valve must remain

closed throughout the charging procedure. The gas

release valve must also be closed unless the vessel

is to be purged, or unless there is to be a continuous

flow through the reactor during a run. Always make

certain that the pressure in the gas tank is greater

than the pressure in the vessel; otherwise liquid

will be forced out of the vessel and into the gas