LINK Systems OmniLink 5000 User Manual

Page 37

April 12, 2012

Manual Version 1.1

5.1

Stroke

Mode

Single Stroke

Drive

Speed

Stroke

Speed

SPM

SPM

0

0

Order

Counter

PC STATUS

Counter OFF

Auto

Sets

EXIT

0

0

Program/Run Switch

TOP

Slide Adjust #1 (ON)

Hydraulic Overload (ON)

Counter-Balance #1 (ON)

Cushion #1 (ON)

Cushion #3 (OFF)

Cushion #2 (ON)

Module Status: All Conditions OK

Setpoint:

Actual

Shutheight

Fault:

Status:

None

In Position

20.000 in

20.000

Die Weight Set:

Actual

Pressure

Fault:

Status:

None

At Pressure

722 lbs

72

Pressure Set:

72 psi

psi

in

Cush Force Set:

Actual

Pressure

Fault:

Status:

None

At Pressure

627 lbs

54

Pressure Set:

54 psi

psi

Cush Force Set:

Actual

Pressure

Fault:

Status:

None

At Pressure

2 Tons

32

Pressure Set:

32 psi

psi

Cush Force Set:

Actual

Pressure

Fault:

Status:

None

System OFF

0 lbs

0

Pressure Set:

0 psi

psi

Press Tons Set:

Actual

Pressure

Fault:

Status:

None

At Pressure

320 Tons

65

Pressure Set:

65 psi

psi

AUTO

ADJUST

CANCEL

AUTO

ADJUST

RESET

ERROR

CHANGE

NUMBER

JOG

DOWN

JOG

UP

CONFIGURE

a

J

i

h

g

f

e

d

c

b

l

k

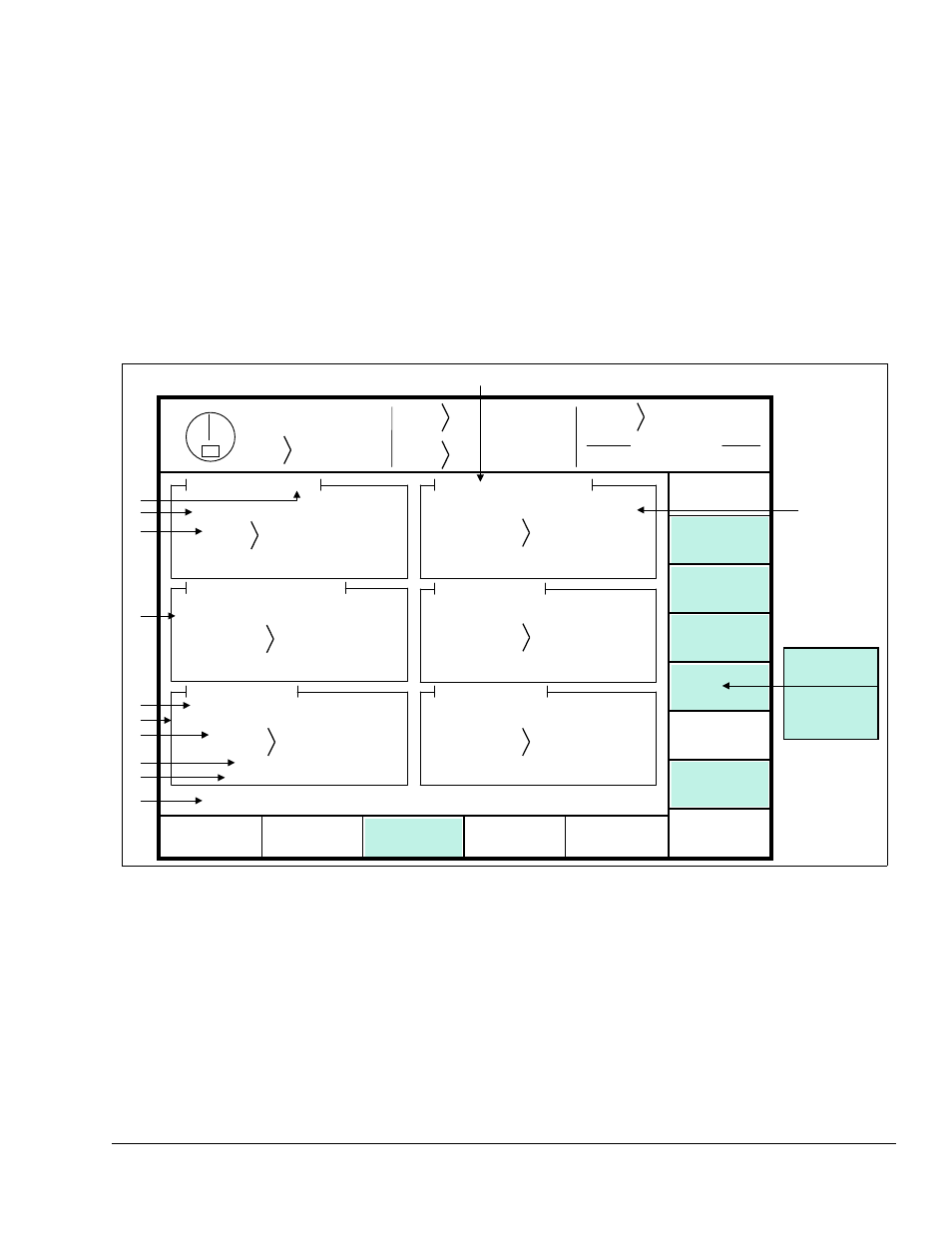

Figure 5.1: Example Auto-Sets Screen

Section 5

Operation

The purpose of the Auto-Setup module is to allow automatic adjustment of such press systems as air

counterbalances, air cushions, air operated hydraulic overloads, and slide adjust systems to greatly

reduce setup time for different jobs, and to help ensure that these systems are adjusted correctly for

different jobs.

All operation of auto-setup functions, other than automatic adjustments to previously stored values

when the OmniLink 5000 recalls a job, start from the Auto-Sets screen. This screen is displayed when

the “AUTO SETS” softkey on the Main Menu or Press Control screen is pressed. The Auto-Sets screen

shows all configured functions and allows their settings to be adjusted. Figure 5.1 shows an example

Auto-Sets screen. Note that each configured function (slide adjust, counterbalance, cushion, or

hydraulic overload) has its own box with name, settings, position or pressure, status, and fault.

The main features of this screen are:

a) The module status gives the overall status of the auto setup module as a whole instead of the

status of a single sub-system, such as a counterbalance. When the module is functioning

properly, thus should read “All Conditions OK”. See section 6.1 for other diagnostic messages.

b) Each configured sub-system has a status. Under normal conditions, this status will read “At

Pressure” for air-based sub-systems such as counterbalances that are within the tolerance setting

of the set pressure. Slide sub-systems will read “In Position” when within the tolerance setting

for the shut height setpoint. See section 6 for an explanation of all status messages for the