LINK Systems OmniLink 5000 User Manual

Page 24

April 12, 2012

Manual Version 1.1

4.2

Stroke

Mode

Single Stroke

Drive

Speed

Stroke

Speed

SPM

SPM

0

0

Order

Counter

PC STATUS

Counter OFF

Auto

Sets

EXIT

0

0

Program/Run Switch

TOP

CHANGE

NAME

Air System Configuration

Transducer Type: Type 4: 200psi, 4-20ma

Tolerance: 2 psi

Fault Time: 30 seconds

Display Weight As: lbs

Min. Die Weight: 0 lbs

Max. Die Weight: 1000 lbs

Minimum Pressure: 5 psi

Maximum Pressure: 90 psi

Mode: ON

Name: Counter-Balance #1

Air Pressure: 56 psi

Hardware Detected: Fill/Dump

Air Slot: AS1

NEXT AIR

SLOT

Help

CHANGE

MODE

CHANGE

MAX PRES

CHANGE

UNIT

CHANGE

MIN FORCE

CHANGE

MAX FORCE

CHANGE

TIME

CHANGE

MIN PRES

CHANGE

TOLERANCE

CHANGE

TIME

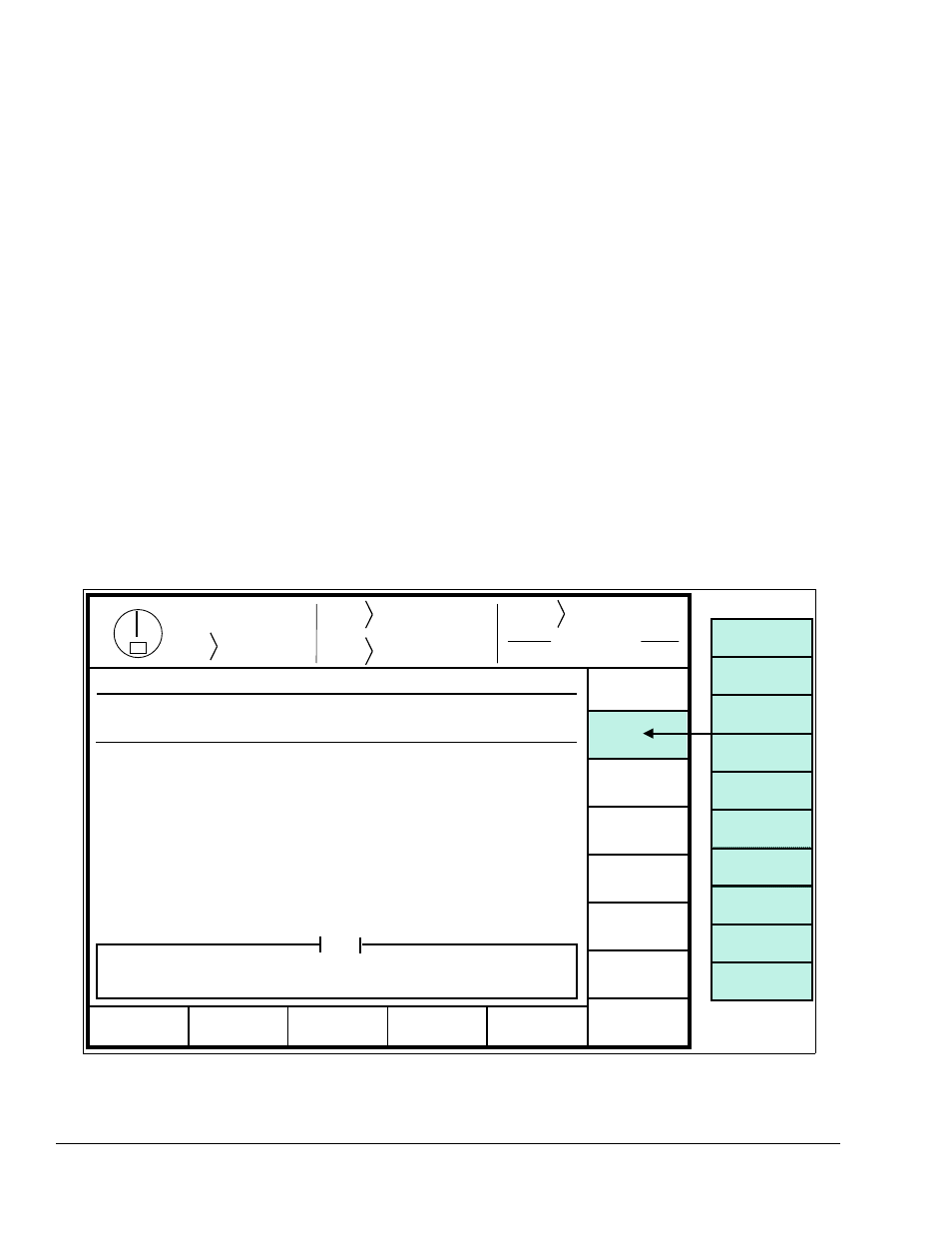

Figure 4.2: Example Air Configuration Screen

Section 4.2 Configuring the Auto-Setup board

The ASM must be configured for the each shut height and pressure module that is installed on it. The

configuration necessary depends on the particular kind of module.

Section 4.2.1 Configuring Counterbalance, Cushion, and Hydraulic Overload Modules

Counterbalances and cushions are conceptually very similar and use essentially the same control

techniques. Hydraulic overloads are somewhat different but are usually air controlled systems (there are

some non-air controlled hydraulic overloads but the auto-setup board does not support them at this

time). To get to the configuration screen for cushion, counterbalance, and hydraulic overload modules:

a) Go to the “Auto Sets” screen. This screen is reached by pressing the “AUTO SETS” softkey in

the Main Menu or Press Control screen.

b) With the RUN/PROG key switch in the PROG position, press the “CONFIGURE” softkey and

enter the configuration code. Note that the code is provided separately from this manual for

administrative control.

c) Press the “CONFIGURE AIR” softkey.

At this point the screen should look similar to Figure 4.2.

There are several parameters that must be configured in this screen. The editing cursor indicates which