Labconco Protector Controlled Atmosphere Glove Box User Manual

Page 55

Chapter 7: Accessorizing Your Glove Box

Product Service 1-800-522-7658

51

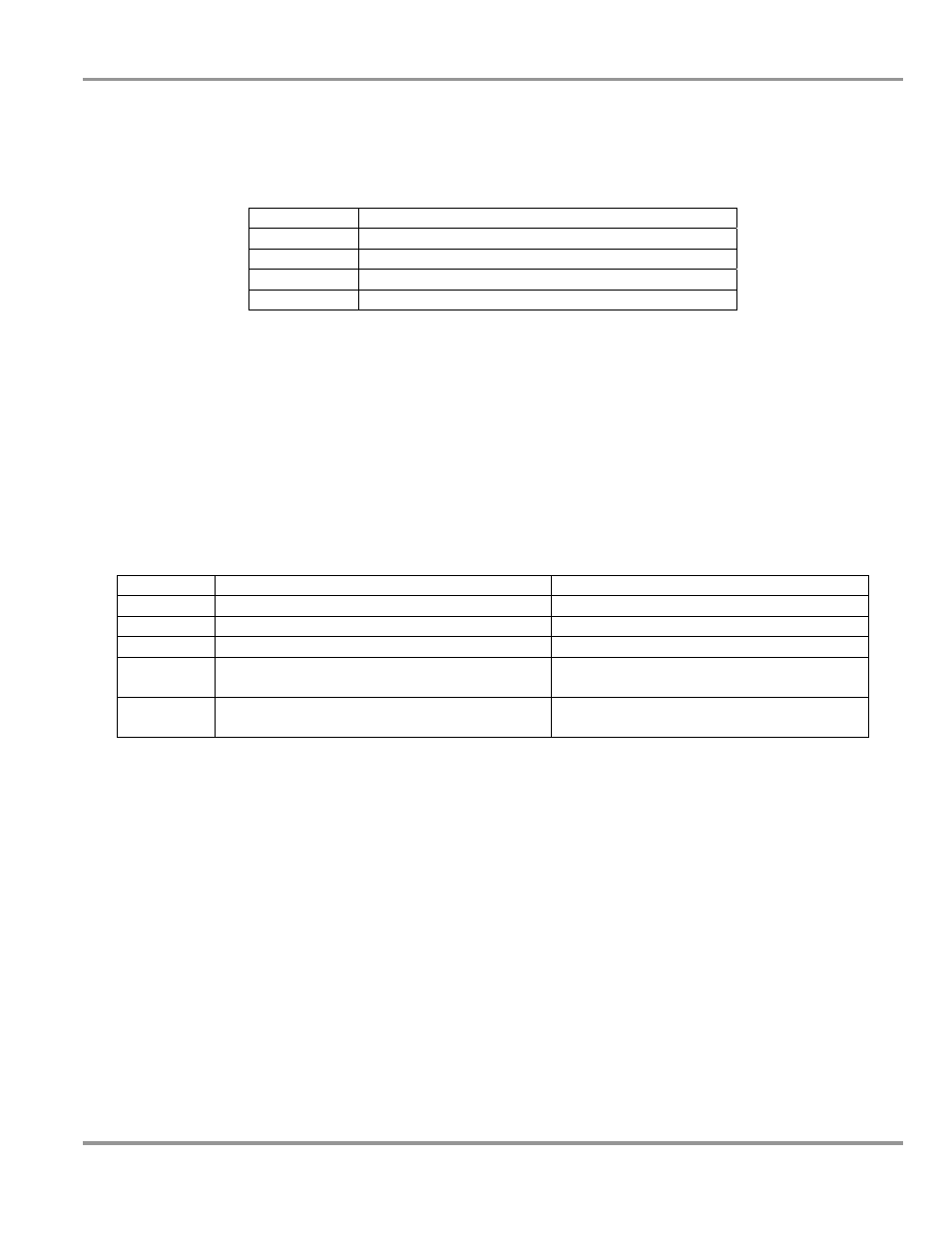

5. Electrical Power Strips

These convenience electrical power strips are available in US and

international versions and plug into the interior receptacle of the

glove box.

Part #

Descriptions

5211500

US Power Strip 115V, 4 Position, 10A

5210601

UK Power Strip 250V, 6 Position, 10A

5290401

European Power Strip 250V, 4 Position, 10A

5332601

Australian Power Strip 250V, 6 Position, 10A

6. Electrical 9 Pin Sealed Pass-Through Kit (Part #5075619)

Includes sealed 9 pin (D-subminiature with male pins on one side and

female pins on the other) connector and cord for data transfer outside

the glove box. Typical data transfer includes oxygen/moisture levels

or analytical balance measurements to a printer.

7. Gas Inlet / Vacuum Outlet Tubing Kits and Direct Drive Vacuum

Pumps

These flexible vinyl tubing kits provide the necessary tubing and

fittings to make connections to an inert gas supply tank and a rotary

vane vacuum pump. See Figures 3-4 and 3-7.

Part #

Descriptions

Used With

5245100

Complete Gas/Vac Tubing Kit (Required)

Manual Valves, all Protector Glove Boxes

5245200

Complete Gas/Vac Tubing Kit (Accessory)

Auto Pressure Controller, accessory only

1472100

Direct Drive Vacuum Pump, 115V, 50/60Hz

All Glove Boxes

7739400

Direct Drive Vacuum Pump, 230V, 50/60Hz,

NEMA 6-15P plug

All Glove Boxes, International Version

7739402

Direct Drive Vacuum Pump, 230V, 50/60Hz

with reverse IEC plug

All Glove Boxes, International Version

8. AtmosPure Re-Gen Gas Purifiers (see catalog #’s below)

The AtmosPure Re-Gen Purifier produces an ultrapure inert

atmosphere for materials sensitive to moisture and/or oxygen by

circulating an inert gas and removing oxygen and moisture inside the

box. Compatible with any Protector or Precise Controlled

Atmosphere Glove Box, the AtmosPure allows the boxes to meet or

exceed ISO 10648-2 test methods. The Purifier has the capacity to

remove up to five liters of oxygen (13,500 ppm) and 660 grams of

moisture (18 million ppm) at standard temperature and pressure

(STP). Depending on the application, glove box liner material and

frequency of use, regeneration may be necessary only once every one

to three months and completed in only 13 hours. See Figure 1-1 in

Chapter 1.