Chapter 3: getting started – Labconco Protector Controlled Atmosphere Glove Box User Manual

Page 27

Chapter 3: Getting Started

Product Service 1-800-522-7658

23

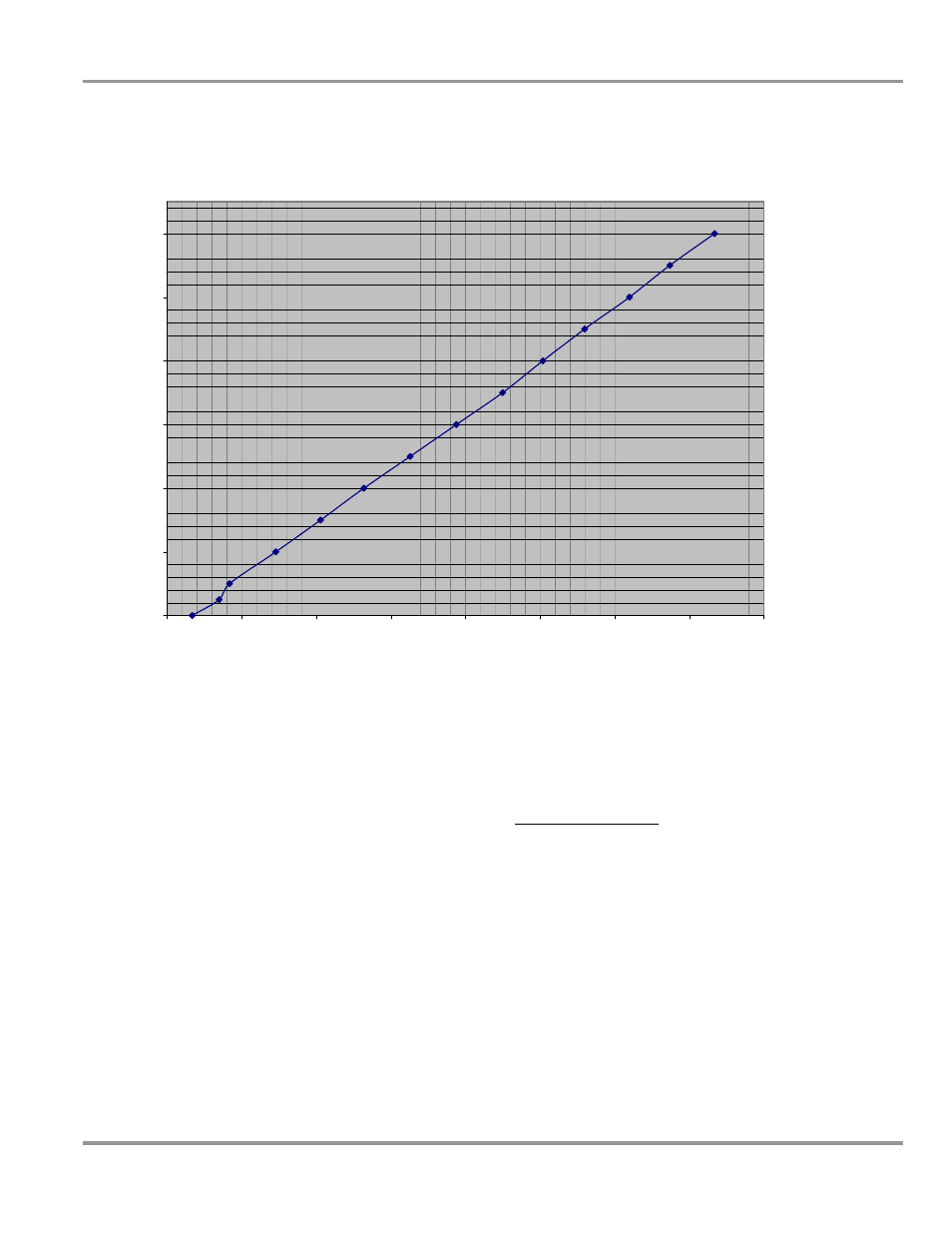

Protector Fiberglass CA Glove Box

Oxygen Permeation at -4" H2O

ISO 10648-2 Test Method

0

20

40

60

80

100

120

0

5

10

15

20

25

30

35

40

Oxygen ppm

Ti

me

M

inute

s

Barometric Pressure

29.61 inches of Hg

Main Chamber

Pressure: -4 Inches

H

2

O

Transfer Chamber

Pressure: 0 inches of

Hg

Leak Rate Box

8.7x10¯

5

Class 1 < 0.0005

Permeation

0.30ppm/min

Figure 3-10

The validation requirements and required testing instruments for all

applications shall be determined by the end user and Safety Officer. Other

validation test methods such as pressure leak decay tests may be conducted per

ISO 10648-2 standards. The pressure leak decay test may be performed, but

the pressure inside the glove box must be adjusted accurately for temperature

and barometric pressure.

These pressure leak decay tests are conducted under negative pressure of

-250 Pa (-1" water gauge) for operational use or -1000 Pa (-4" water gauge)

for the acceptance test; the pressure leak decay tests are usually performed

under stable barometric pressure and temperature conditions to minimize the

effect of these variables.

A 0.1°C fall in temperature results in an equivalent pressure change of -34

Pa or -0.14 inches of water gauge. A 0.01 inches of mercury rise in

barometric pressure results in an equivalent pressure change of -34 Pa or

-0.14 inches of water gauge.