Exhaust port, Electrical connection, Rotor installation – Labconco CentriVap Complete Vacuum Concentrator 73150 Series User Manual

Page 12: Chemical resistance of centrivap components, Chapter 3: getting started, Original instructions

Chapter 3: Getting Started

Product Service 1-800-522-7658

8

Original instructions

Exhaust Port

If the CentriVap is not located in a fume hood, attach one end of a user-supplied

3/8" ID hose to the exhaust port on the back of the unit. Clamp securely. Route

the other end to a fume hood or other laboratory ventilation device.

Electrical Connection

Plug the power cord into the receptacle on the back of the CentriVap Concentrator

and plug the other end into a suitable power receptacle.

Rotor Installation

Place the rotor onto the shaft of the Concentrator. Rotate the rotor slightly to

engage the drive pin in the shaft with the slots in the rotor hub. The top of the

shaft should be in line with the top of the rotor hub.

IMPORTANT: Do not use a rotor if it shows any signs of damage.

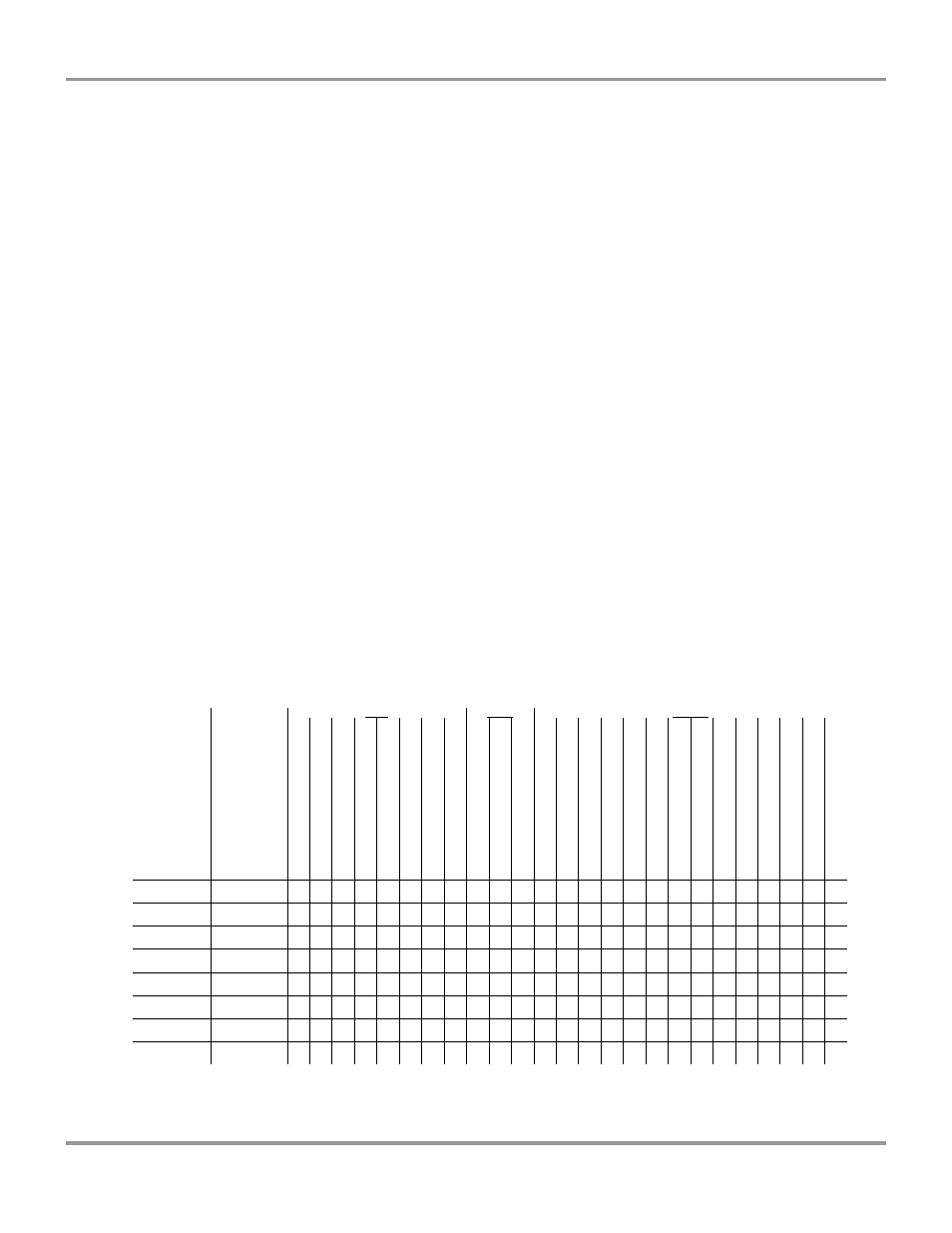

Chemical Resistance of CentriVap Components

Your CentriVap Complete is designed to be chemical resistant to most

compounds that are commonly used in the concentration processes that are

performed in it. However, by necessity, the CentriVap is comprised of a number

of different materials, some of which may be attacked and degraded by certain

chemicals. The degree of degradation is obviously dependent on the concentration

and duration of exposure. Some major components of the CentriVap that are

susceptible to degradation are as follows:

Acids Bases Solvents

COMPONENT MATERIAL

Aceti

c Aci

d 20%

Bor

ic Aci

d

Fo

rmic A

cid

H

ydr

obr

om

ic

Aci

d

20%

H

ydr

ochl

or

ic

Aci

d

20%

Nitric A

cid

2

0

%

S

u

lfu

ric A

cid

1

0

%

Tr

ifl

uor

oaceti

c Aci

d

(

T

FA)

Am

m

oni

um

H

ydr

oxi

d

e

Aceto

ne

A

ce

ton

itrile

Ch

lo

ro

fo

rm

D

im

ethyl

For

m

a

m

ide

D

im

ethyl

Sul

foxi

de (

D

M

SO)

Etha

nol

Ethyl

Ac

etat

e

H

e

xanes

Isopr

op

on

al

M

ethan

ol

M

e

thyl

en

e C

h

lo

ride

M

e

thyl t-

Bu

tyl Eth

e

r (

M

T

BE)

Tol

uen

e

Wa

te

r

Rotor

Hub

Polypropylene

C

C

Chamber

Epoxy coated

Aluminum

C

D

C

D

Tubing

PVC

D C D D D D D D C D D D D

Lid Gasket

EPDM

D

D

C

D

Cold Trap

Gasket

Neoprene

D D C D D C D D D D D C D

Rotor

Anodized

Aluminum

D

D

Rotor Shaft &

Cold Trap

Stainless

Steel

D

D

D

Bearings

High Carbon

Steel

D

D

D

D

D

D

D D D

C-Moderate Degradation-Questionable use

D-Severe Degradation-Infrequent use recommended-immediate thorough cleaning required