HITEC Razzor User Manual

Page 16

Operating Instructions

MULTIcont BL-15 brushless controller

MULTIPLEX Modellsport GmbH & Co.KG • Westliche Gewerbestraße 1 • D-75015 Bretten • www.multiplex-rc.de Page 1/4

A

n

le

it

u

n

g

M

U

L

T

Ico

n

t

B

L

-1

5

#

8

2

5

9

5

9

(1

2

-0

4

-2

6

/B

R

A

N

)

•

E

rr

o

rs

a

n

d

o

m

issi

o

n

s

e

xce

p

te

d

.

•

M

U

L

T

IP

L

E

X

!

These operating instructions are an integral part of this

product. They contain important information and safety

notes, and should therefore be kept in a safe place at all

times. Be sure to pass them on to the new owner if you ever

dispose of the product.

1.

S

AFETY

N

OTES

!

Read the instructions before using the controller

!

Avoid heat build-up

Provide unobstructed air circulation round the controller

!

Do not connect the flight battery with reversed polarity

Connecting the battery leads with reversed polarity will

instantly wreck the controller

For this reason:

• red wire to the POSITIVE terminal (+)

• black wire to the NEGATIVE terminal (-)

!

When soldering or working on the motor or controller

Always disconnect the battery (short-circuit / injury hazard)

!

When testing and running the power system

Do not run the motor while holding it in your hand; always

secure the model firmly. Check that there is adequate space

for the propeller to rotate. Remove all objects from the area

around the propeller which could be sucked in or blown away

(clothing, paper etc.). Never stand in the rotational plane of

the propeller (injury hazard).

2.

S

PECIFICATION

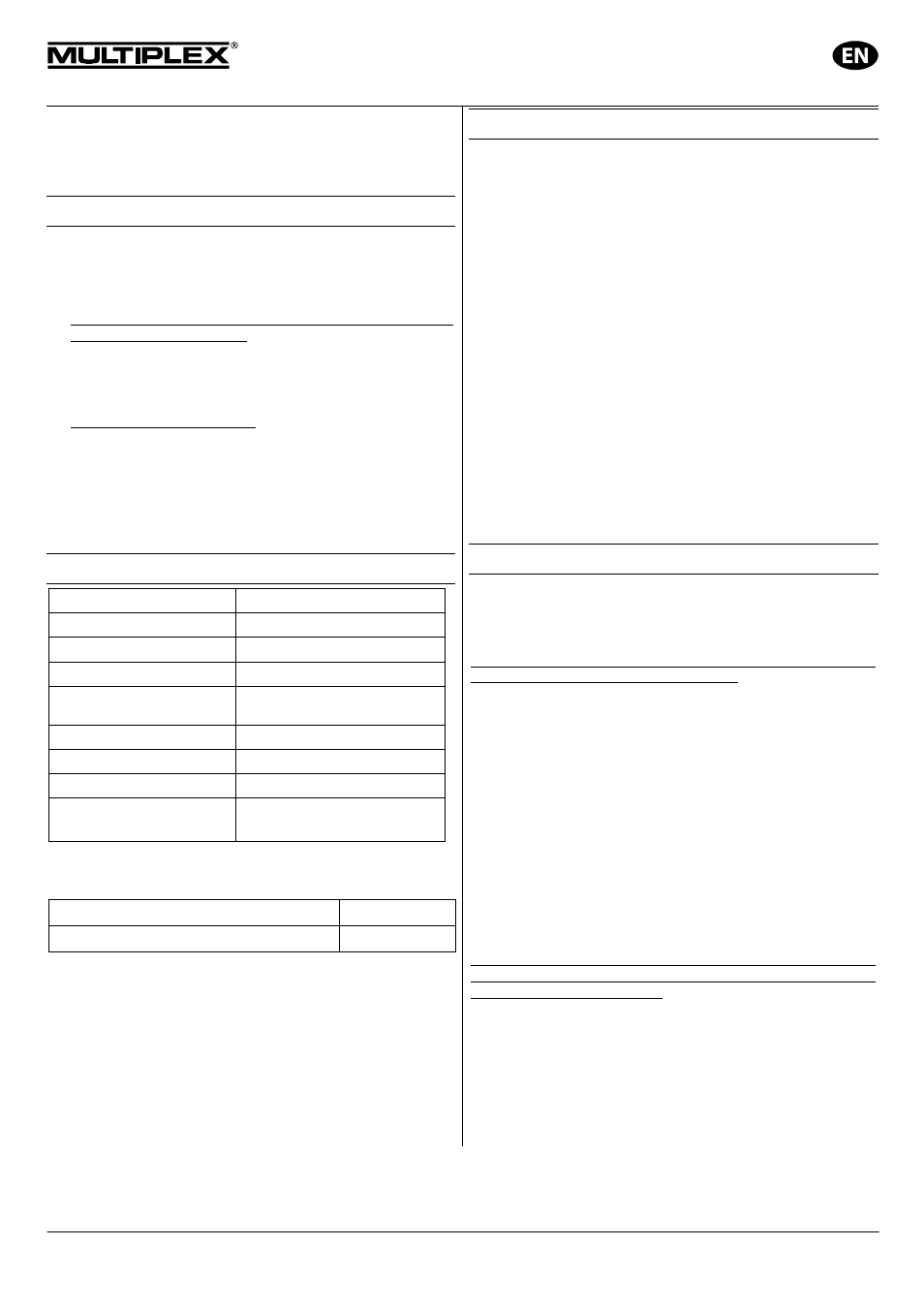

MULTIcont BL15

BL-15

Order No.:

# 7 2265

max. continuous current:

15 A

Pulse frequency:

8 kHz or 16 kHz (adjustable)

Receiver power supply

max. 3S LiPo or

9 NiXX cells

BEC voltage:

5.0 V

BEC current:

max. 2.0 A

Dimensions in mm (approx.):

40x25x9

Weight incl. leads (approx):

ca 22 g

Maximum number of servos usable with MULTIcont BL-15

controllers in BEC mode**

MULTIcont

BL-15

Maximum number of micro / standard servos*:

4

* MULTIPLEX Nano-S or Tiny-S servo types.

** If the number of servos in the model exceeds the stated

maximum, it is essential to disable the BEC system and use a

separate receiver battery (

7.).

3.

S

PECIAL

F

EATURES

MULTIPLEX MULTIcont BL-15 controller offers an excellent

range of additional features:

•

numerous programmable parameters

- low-voltage cut-off for: LiPo and NiXX batteries

- brake: ON or OFF

- motor reverse: on or off

- motor cut-off type: motor power reduction or motor cut

- motor start behaviour: soft or standard

- timing: automatic or manual (7 degrees or 22 - 30 degrees)

- pulse frequency: 8 kHz or 16 kHz

- model type: fixed-wing or helicopter (governor mode)

These parameters are programmable using the

transmitter throttle stick.

!

But not with the MULTIPLEX MULTImate # 8 2094 or PC.

•

With BEC (Battery Eliminator Circuit)

receiver power supply from the flight battery.

•

Start-up safety system prevents the motor bursting into life

when the flight battery is connected

•

Motor cut if major interference occurs or the transmitter signal

fails

•

Automatic low voltage cut-off with re-start facility (Reset

function) for LiPo and NiXX cells

4.

W

IRING

!

Note: if you wish to use a different connector system for

connecting a MULTIcont BL-15 speed controller to your

motor and / or battery, please note the following infor-

mation:

Soldering requires some care, as the quality of the joints is

crucial to the reliability of the power system:

•

Use electronic-grade solder for all soldered joints

•

Do not use acid-based solder flux

•

Parts to be soldered must be hot enough (the solder must

flow), but must not be overheated (damage to components)

•

If you are unsure, ask a modeller with experience in soldering

to help you

•

Carefully insulate all solder joints and bare wires (e.g. using

heat-shrink sleeving)

Attaching the battery connectors

The battery connectors have to be attached to the two wires (red

= +, black = -). Keep the wires as short as possible. If necessary,

cut the battery leads to the required length. Fit a piece of heat-

shrink sleeve on each wire, and shrink the sleeve over the

soldered joint.

Take great care to maintain correct polarity when soldering the

battery connectors to the leads. Reversed polarity inevitably and

invariably wrecks the controller.

Connecting the speed controller to the motor

The motor is connected to the three wires which exit one end of

the controller. Solder sockets to the wires which match the motor

connectors, and insulate each soldered joint with a separate

heat-shrink sleeve. Keep the leads as short as possible.

If you need to reverse the direction of rotation of the motor,

simply swap over two of the three wires leading to the motor;

alternatively change the direction by programming (

6.3.).