Hanna Instruments HI 83216 User Manual

Page 3

4

5

A major family leisure pursuit is the enjoyment of Swimming Pool and Spa facilities world-wide. A basic necessity

of Pool water treatment, to ensure such enjoyment, is to maintain the water in a safe and pleasant condition

for the bathers.

In order to achieve such an objective, swimming pool water requires testing on daily, and sometimes hourly bases

for disinfection residuals and pH. Equally important, Calcium Hardness and Alkalinity parameters should be

monitored on weekly bases to ensure the pool water is maintained in a balanced condition, thus to avoid system

failure because of corrosion or scale formation.

DISINFECTION RESIDUAL AND pH CONTROL

In terms of swimming pool treatment, disinfection or sanitizing basically means to rid the pool of bather pollution,

destroy bacteria, and control nuisance organisms like algae, which may occur in the pool, filtration equipment,

and piping.

There are a number of techniques used, namely, chlorine, bromine and ozone dosing systems, of which chlorine

is the most common.

Chlorine

Chlorine is a strong oxidizing agent that destroys mostly organic pollutants, bacteria and can combine with

nitrogen containing compounds, forming chloramines. Only a part of the original quantity dosed chlorine,

remains active and continues its disinfecting action.

From the

free chlorine you can distinguish combined chlorine, as that part which combines with nitrogen

containing compound and that is less efficient as a disinfectant. The addition of these two parts gives

total

chlorine. A pool manager needs to aim perfection where free equals total chlorine, and thus to maintain the

combined chlorine concentration near zero. The presence of chloramines is not desired because of the distinctive

‘swimming pool’ smell caused by combined chlorines like di-chloramines. Beside this unpleasant odour it does

irritate the eyes and the mucous membranes.

Commercially chlorine for disinfection may be available as a gas (

Cl

2

), a liquid like sodium hypochlorite or bleach

(

NaOCl) or in a solid state like calcium hypochlorite, chloro-hydantoins or chloro-cyanuric acid compounds. These

compounds, once dissolved in water do establish equilibrium between the hypochlorous acid (

HOCl) and the

hypochlorite ions (OCl¯). Although both forms are considered free chlorine, it is the hypochlorous acid that

provides the strongest disinfecting and oxidising characteristic of chlorine solutions.

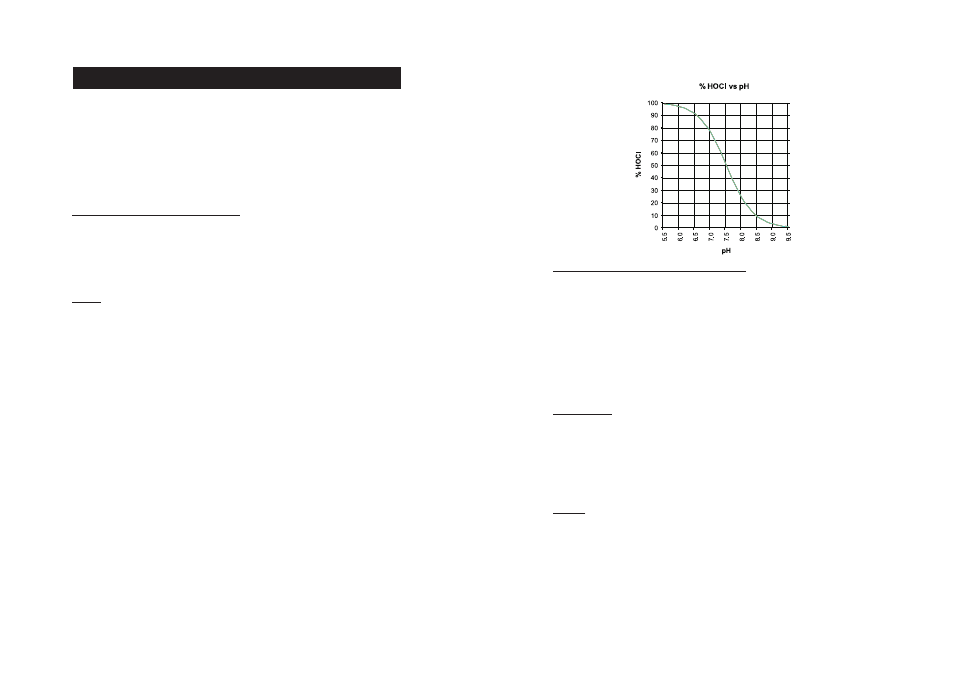

The amount of hypochlorous acid in chlorinated water dependends upon the pH value of the solution. Changes

in pH value will effect the HOCl equilibrium in relation to the hydrogen and hypochlorite ion.

As depicted by the curve on the next page, HOCl decreases and OCl¯ increases as pH increases. At a low pH,

almost all the free chlorine is in the molecular form HOCl and at a pH of around 7.5, the ratio between HOCl and

OCl¯ is 50:50. Since the ionic form OCl¯ is a slow acting sanitizer while the molecular HOCl is a fast acting, it

is important to measure regularly the pH. As a general rule a pH of about 7.2 is recommended to maintain fast

acting disinfection conditions.

SIGNIFICANCE OF POOL AND SPA TESTING

THE WATER BALANCE AND LANGELIER INDEX (LI)

The pool water characteristics need to be maintained in a balanced condition to avoid system failure. Measuring

the water balance is extremely important to predict if the water is corrosive, scaling or balanced.

A saturation index developed by Dr. Wilfred Langelier is widely used to predict the balance of swimming pool

waters. It is an estimation of the solutions ability to dissolve or precipitate calcium carbonate deposits. A certain

level of this precipitation (filming) is desired to insulate pipes and boilers from contact with water. When no

protective filming is formed, water is considered to be corrosive. On the other hand scaling does cause failure

because of incrustation problems.

In the treatment and monitoring of pool water, the pool manager must ensure that related parameters as

alkalinity, hardness and pH are duly taken into consideration.

Calcium Hardness

The presents of calcium in the system is desired to ensure filming on those places where the temperature is

relatively high, like in boilers and pipes transporting warm water. Scaling must be avoided because it reduces

heat transfer and pump capacity. Beside the calcium carbonate deposits in the pipes, high scaling values do

cause cloudy water.

It is recommended to maintain the calcium hardness value within the range from 200 to 400 ppm as calcium

carbonate (CaCO

3

).

Alkalinity

Alkalinity is the measure of the total concentration of alkaline substances, mostly bicarbonates, dissolved in the

water. The higher the alkalinity the more resistant the water is to pH change, the alkalinity

buffers the water.

At the same time, high alkaline water is a major contributor to scaling problems like incrustation in filtration

equipment, pumps, and piping.

It is recommended to maintain the alkalinity value within the range from 80 to 125 ppm as calcium carbonate

(CaCO

3

).