Measurement units, Principle of operation, Lcd backlight tag installation – Hanna Instruments HI 83749 User Manual

Page 6: Lamp replacement

6

Many methods were used to measure turbidity over the years. The Jackson Candle Turbidimeter was

used to measure turbidity as Jackson turbidity units (JTU). The Secchi Disk is commonly used to

measure turbidity in lakes and other deep waters (mg/L SiO

2

). Both methods are visual and are not

considered very accurate. To obtain more accurate readings a nephelometer should be used as a

turbidity reading instrument.

The HI 83749 turbidimeter reports the measurements in NTU (Nephelometric Turbidity Units).

NTU units are equal to FTU units (Formazine Turbidity Units). The conversion table between these

measurement units is shown bellow:

U

TJ

U

T

F/

U

T

N

Oi

S

2

)L

/g

m

(

U

TJ

1

9

1

0

5.

2

U

T

F/

U

T

N

3

5

0.

0

1

3

1.

0

Oi

S

2

)L

/g

m

(

4.

0

5.

7

1

MEASUREMENT UNITS

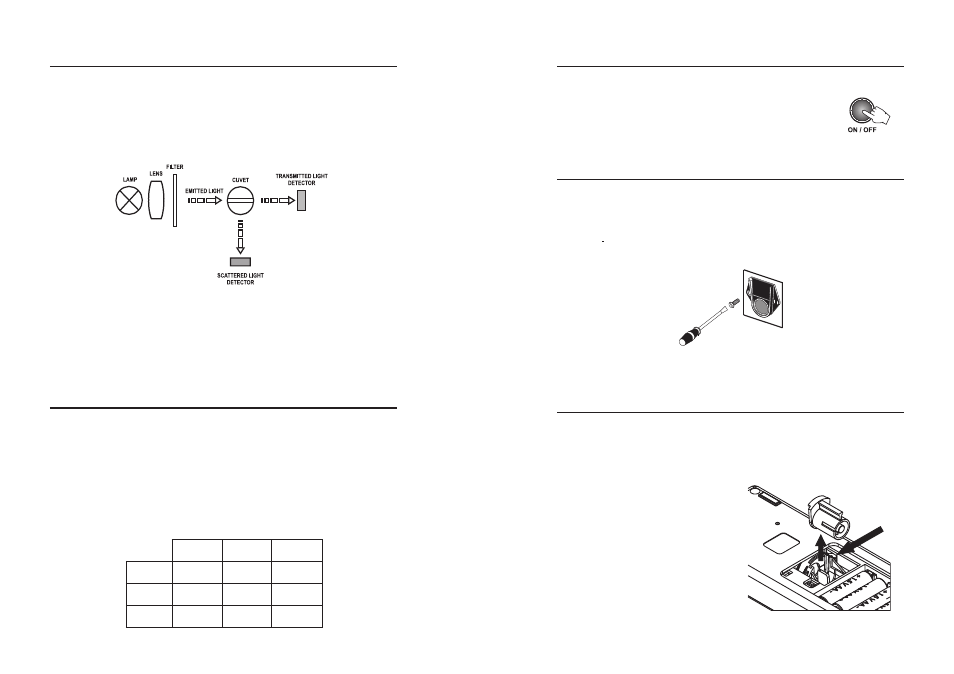

A light beam that passes through the sample is scattered in all directions. The intensity and pattern of

the scattered light is affected by many variables like wavelenght of the incident light, particle size,

shape, refractive index and color.

The optical system includes a tungsten filament lamp, a scattered light detector (90

0

) and a transmitted

light detector (180

0

). The microprocessor of the instrument calculates the NTU value from the signals

that reaches the two detectors.

The lower detection limit of a turbidimeter is determined by the so called “stray light”. Stray light is

the light detected by the sensors, that is not caused by light scattering from suspended particles.

The optical system of HI 83749 turbidimeter is designed to have very low stray light, providing

accurate results also for low turbidity samples. However, special care must be taken when measuring

low turbidities (see General Tips for an Accurate Measurement, page 10).

PRINCIPLE OF OPERATION

35

The LCD can be illuminated to allow the user to see the readings even in dark

environments.

To turn on or off the backlight, press the ON/OFF key.

The backlight will automatically shut-off after 25 seconds of non-use to save

the battery life.

The tag is housed in a rugged metal that can withstand harsh environments. However, it is better

to protect the tag from direct rain.

Place the tag near a sampling point. Fix it securely with the provided screws, in such a way that

the metallic iButton

®

is easily accessible for reading the tag.

The number of tags that can be installed is practically unlimited. Additional tags can be ordered

(See Accessories, page...) HI 920005 - five tag holders with tags).

LCD BACKLIGHT

TAG INSTALLATION

The instrument tungsten lamp has a life longer than 100,000 measurements. In case of lamp failure,

the defective lamp can be easily replaced. When the lamp is broken, the instrument displays “no L”

error message.

To replace the lamp follow the next steps:

• Remove the battery lid.

• Unscrew the lamp connection using a screwdriver.

• Unlock the lamp and extract it by pulling it out

from the lamp holder handler.

• Place the new lamp in the right position and

push it until is securely locked.

• Insert the lamp leads into the connector and

tight them using a screwdriver.

Warning: After lamp replacement the meter needs

to be recalibrated.

LAMP REPLACEMENT