Fault conditions and selftest procedures, Startup – Hanna Instruments mV 600 Series User Manual

Page 22

43

42

FAULT CONDITIONS AND SELFTEST PROCEDURES

The fault conditions below may be detected by the software:

• EEPROM data error;

• I2C internal bus failure;

• code dead loop.

EEPROM data error can be detected through EEPROM test

procedure at startup or when explicitly requested using setup

menu.

When an EEPROM error is detected, user is given the option

to perform a reset of EEPROM. Thus the reset can be per-

formed whenever needed. It may be useful to provide a means

to reset EEPROM directly (without a previous EEPROM error

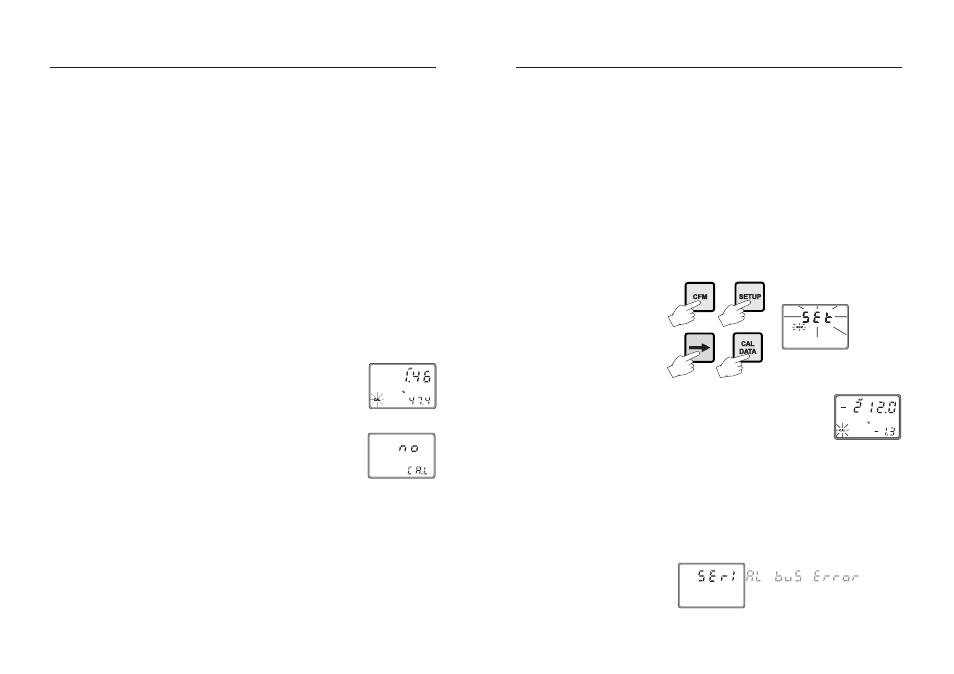

detection). This is done by pressing CFM first and then SETUP,

and CAL DATA simultaneously.

Note

When an EEPROM reset has been per-

formed calibration data are reset to

default. An intermittent CAL will blink

on the display to advise the user of

this status.

A I2C failure is detected when the I2C transmission is not

acknowledged or a bus fault occurs for more than a certain

number of attempts (this can be due, for example, to dam-

age sustained by one of the ICs connected to I2C bus).

If so, the controller stops any tasks and displays a perpetual

sliding message “Serial bus error” (i.e. this is a fatal error).

STARTUP

At startup the firmware release code scrolls through the LCD;

it is possible to escape from code scrolling pressing any key.

During the automatic startup the Real Time Clock (RTC) is

checked to see if a reset occurred since last software ini-

tialization. In this case, the RTC is initialized with the default

date and time 01/01/1997 - 00:00. An EEPROM reset

does not affect the RTC settings.

The EEPROM is also checked to see if it is new. If this is the

case, the default values are copied from ROM and then

the device enters normal mode. Otherwise an EEPROM

checksum test is performed (the same is performed during

EEPROM selftest procedure).

If checksum is correct, normal mode is entered, otherwise

user is asked whether the EEPROM should be reset.

If EEPROM reset is requested, default values from ROM

are stored into EEPROM as would happen with a new

EEPROM.

Note that EEPROM data is composed of setup data and

calibration data. As for the setup data, the calibration data is

assigned default values when an EEPROM reset occurs. An

un-calibrated meter can perform mea-

surement, though user is informed that

pH calibration (pH models) or mV cali-

bration (mV models) is needed by

means a blinking “CAL” icon.

When the last calibration data is re-

quired, the “no CAL” message is

displayed if no calibration procedure

was performed.

Unlike pH and mV calibration, user has no information on

calibration need for other magnitudes, other than the aware-

ness that EEPROM was reset.

After an EEPROM reset, all calibrations (input and output)

have to be performed in order to obtain correct measure-

ments.