Hanna Instruments HI 98713 User Manual

Page 7

12

13

GENERAL TIPS FOR AN ACCURATE MEASUREMENT

GENERAL TIPS FOR AN ACCURATE MEASUREMENT

GENERAL TIPS FOR AN ACCURATE MEASUREMENT

GENERAL TIPS FOR AN ACCURATE MEASUREMENT

GENERAL TIPS FOR AN ACCURATE MEASUREMENT

CUVET

The cuvet is part of the optical system in all measurements. The light reaches the sample by

passing through the cuvet glass. As a result, the measurement can be affected by the glass

imperfections, dirt, dust, scratches, or fingerprints present on the cuvet surface.

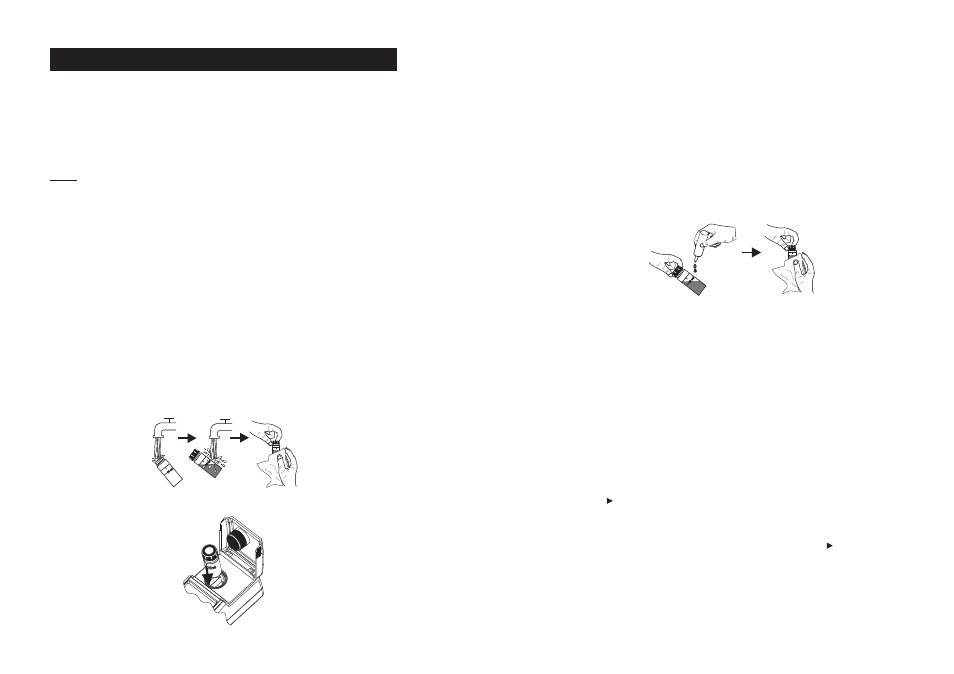

CUVET HANDLING

The cuvets should be free of scratches or cracks. Any cuvet with visible scratches will be

discarded. The cuvets should be periodically washed with acid. After washing, the cuvets should

be well rinsed many times with distilled or deionized water. Allow cuvets to air-dry and store

them for long periods of time with caps, to avoid dirt entering inside. Always handle the cuvet

by touching only the cap or its top side (over the horizontal line).

Always store the cuvets in separate boxes or with separators between them to avoid scratches on

the surface.

CUVET PREPARATION

Whenever a cuvet is used, it must be clean inside and outside. When it is placed into the

instrument, it must be dry outside, completely free of fingerprints or dirt.

If the cuvet is not indexed, put the cuvet with the factory mark aligned with the sign on the

instrument top.

HI 98713 is a highly accurate turbidimeter. To meet the instrument performance and fully

benefit of its properties it is very important that the analyst perform accurate, precise and

repeatable readings using proper measurement techniques. Special care must be taken during

sample preparation and handling.

The instructions listed below should be carefully followed during measurement and calibration to

ensure best accuracy.

CUVET OILING

To hide minor imperfections and scratches, the cuvets should be oiled outside with the supplied

silicone oil. This is very important, especially for low turbidity samples (< 1 FNU), otherwise

scratches can contribute and alter turbidity readings.

The silicone oil has the same refractive index as the glass and will not alter the turbidity readings.

It is important to apply only a thin layer of silicone oil.

Warning: Do not apply the oil in excess, it may retain dirt or contaminate the cuvet holder of the

instrument, altering the turbidity readings.

It is very important to apply the silicone oil on a clean, dry cuvet. Apply a few drops of oil and wipe

the cuvet thoroughly with a lint-free cloth. Wipe off the excess of oil till you obtain a thin, uniform

layer. If the procedure is correctly followed, the cuvet should appear nearly dry with no visible oil.

Note: The supplied cloth for oiling should be stored together with the silicone oil bottle and cuvets,

taking care to avoid contamination with dirt. After a few oiling procedures the cloth will

contain enough oil to wipe the bottle with it without adding more oil. From time to time add

some drops of oil on the cuvet to provide the necessary oil quantity in the cloth.

INDEXING A CUVET

It is very important for low turbidity readings to always insert the cuvet into the instrument in the

same position.

All cuvets are factory indexed. This index can be used to put the cuvet with the factory mark on the

cuvet aligned with the sign on the instrument top.

To further reduce the effect of glass imperfections, the cuvet can be indexed and use this new index

as the position mark.

For indexing one cuvet or matching multiple cuvets the continuous reading mode is suggested. In this

mode if READ is kept pressed, multiple successive readings are taken without turning off the LED.

After first reading is displayed, it is possible to open the cuvet lid and rotate the cuvet without

generating an error condition. The turbidity is immediately displayed, reducing drastically the

measurement time. The LED of the instrument will turn off only when READ is released.

Note: The instrument can not perform continuous readings if the average mode is on.