7 fire installation, 6 commissioning, 8 servicing – Glow-worm Inset 40BBU User Manual

Page 18

18

221722B

7 Fire Installation

Fire Front Installation and Servicing Instructions are packed

with the fire.

7.1 Completion - After Installation of the Fire

Front

Instruct and demonstrate to the user, the efficient and safe

operation of the boiler, heating and hot water system and fire

front.

Hand the Instructions for Use to the user, making sure that they

are understood.

Advise the user that to ensure the continued efficient and safe

operation of the appliance it is recommended that it is checked

and serviced as necessary at regular intervals. The frequency

of the servicing will depend upon the particular installation

conditions and usage, but in general once a year should be

enough.

Draw attention, if applicable, to the current issue of the Gas

6 Commissioning

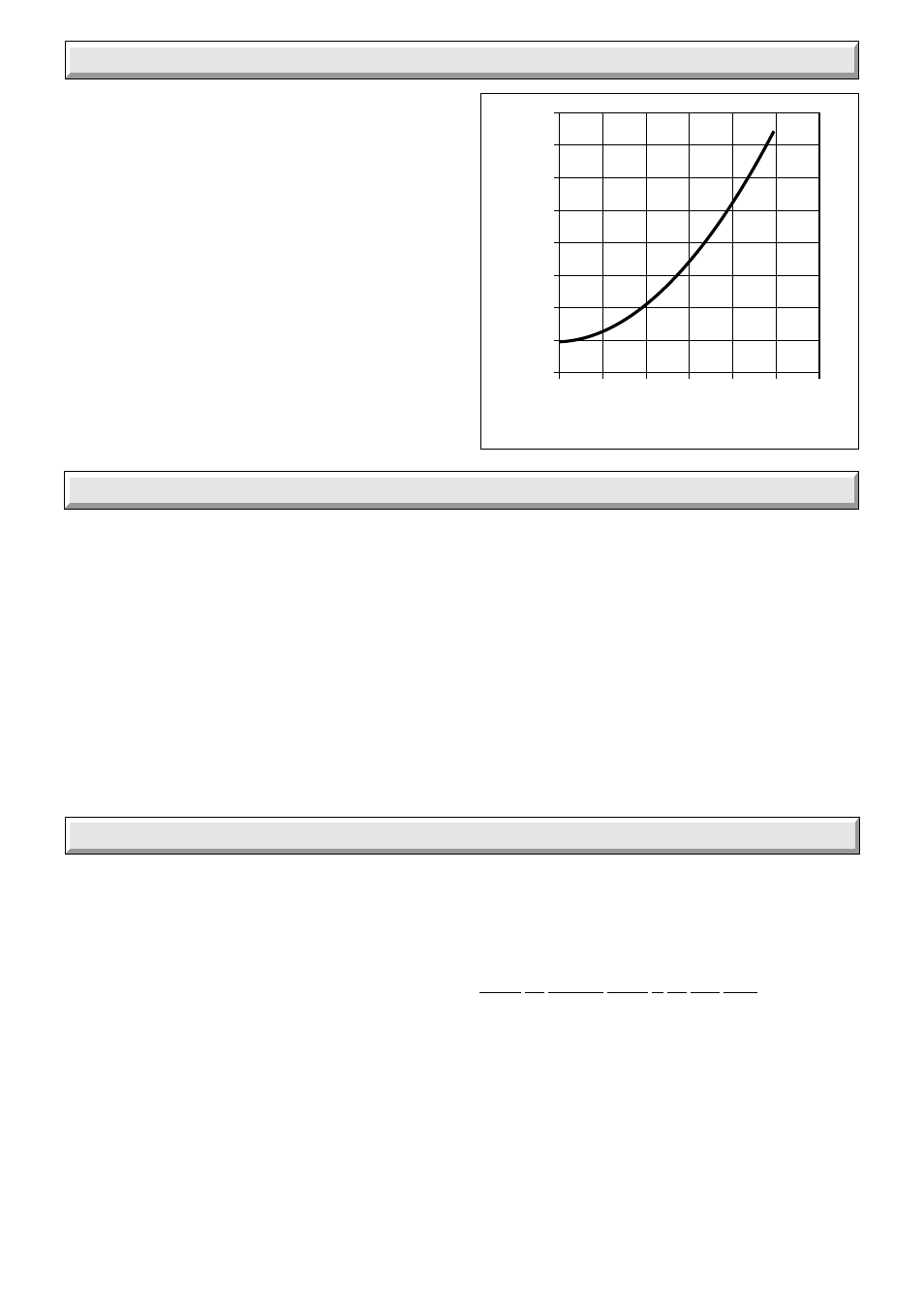

Diagram 6.4

6.4 Commissioning the System

Set all controls to operate the heating system. Adjust circulating

pump and balance the system to give a temperature drop

across the boiler of 11

o

C (20

o

F). At the appropriate flow rate, the

resistance of the back boiler can be found by reference to

diagram 6.4.

There should be no undue noise in the pipework or heat

emitters. There must be NO pumping over of water or entry of

air at the open vent pipe above the feed and expansion cistern.

Make sure the back boiler control thermostat knob “A” is turned

clockwise to “MAX”, which is about 82

O

C (180

O

F),

against the

setting point, allow the water to reach maximum working

temperature. Examine the system for water soundness.

Turn the control thermostat knob “A” anti-clockwise to “Off” and

rapidly drain the system whilst still hot, to complete the flushing

process.

Refill the system, vent and check again for water soundness.

PRESSURE LOSS (mm head of water)

FLOW RATE (litres / minute)

700

600

500

400

300

200

100

0

5

10

15

20

25

30

0

-100

6240

Safety (Installation and Use) Regulations, Section 35, which

imposes a duty of care on all persons who let out any property

containing a gas appliance.

It is the law that any servicing must be carried out by a

competent person.

Set any remote controls for the system to settings requested by

the user.

Advise that the boiler is fitted with a flue blockage safety device

and refer to the Instructions for Use.

Advise the user of the importance to keep any purpose built

ventilation system where the appliance is installed, clear of any

obstruction that would impede its efficiency.

Reminder, leave these instructions with the user.

Advise the user that the ‘Benchmark’ logbook should be

completed by the installation engineer on completion of

commissioning or servicing.

8 Servicing

Servicing Notes

a) To ensure the continued efficient and safe operation

of the appliance it is recommended that it is checked

and serviced as necessary at regular intervals. The

frequency of the servicing will depend upon the

particular installation conditions and usage, but in

general once a year should be enough.

b) It is the Law that servicing must be carried out by a

competent person.

c) Remove the fire front

d) Refer to the Gas Fire Front Installation and Servicing

Instructions for full details of fire front removal.

e) After completing any servicing always test for gas

soundness with a suitable leak detection fluid and

carry out functional check on controls.

f) Unless stated otherwise reassembly of all components

is in the reverse order to that for removal.

8.1 Isolation of Services

With the fire front removed.

Refer to diagram 6.1 to identify the controls.

Turn control thermostat knob “A” anti-clockwise to “0” “Off”

position.

Isolate the electrical supply to the back boiler.

Turn appliance gas service cock to “Off”, see diagram 6.2.

8.2 Sensing Tube Assembly.

Remove the sensing tube securing screw, carefully pull the

sensing tube assembly away from the sensing tube fitting on the

draught diverter and from the flue blockage safety device.

Remove the sensing tube fitting and the tubing nut to access the

filter.

Clean or replace the filter, check the “O” rings for damage,

replace if necessary, see diagram 8.1.

IMPORTANT NOTE: When replacing the sensing tube check

the “O” rings and filter are fitted.