Glow-worm hxi and Gas Valve User Manual

Page 46

Requirements

It is the Law that any replacement of parts is carried out by a

competent person approved at the time by the Health and Safety

Executive.

Before commencing with the replacement of a part the boiler

should be isolated from the electrical supply and the gas supply

should be turned off at the gas isolation valve.

When replacing a part, use only spare parts that you can be

assured conform to the safety and performance specification that

we require. Do not use reconditioned or copy parts that have

not been clearly authorised by Glow-worm.

After electrical connections have been made, checks to the

earth continuity, polarity, short circuit and resistance to earth

must be repeated using a suitable multimeter.

Unless stated otherwise, parts are replaced in the reverse order

to their removal.

After replacing these parts you MUST always test for gas

soundness and carry out functional test of the controls and

check the following:

General Inspection

After the replacement of a part, the following must be

checked.

● The integrity of the flue system and flue seals.

● The integrity of the appliance combustion circuit and

relevant seals.

● Electrical, gas and water connections.

● System pressure.

● the combustion performance, operational gas inlet

pressure and gas rates

.

refer to the following procedure.

ALL MODELS

Refer to the installation and servicing instructions supplied

with your boiler to fit the replacement gas valve.

IMPORTANT. If the Burner Door was Removed

Fit the new combustion door seal kit fitted in accordance

with the instructions provided.

Re- assembly

After assembly test for gas soundness and purge in

accordance with the current issue of BS6891 or in IE, the

current edition of I.S.813 “Domestic Gas Installations”.

Do not fit the inner or front case until the commisioning has

been carried out as described in the following sections.

COMPETENCY TO CARRY OUT THE CHECK

OF COMBUSTION PERFORMANCE

NOTE: BS 6798: 2009 Specification for installation

and maintenance of gas-fired boilers of rated input not

exceeding 70kW net advises that:

● The person carrying out a combustion measurement

must be assessed as competent in the use of a flue gas

analyser and the interpretation of the results.

● The flue gas analyser used should be one meeting

the requirements of BS7927 or BS-EN50379-3 and be

calibrated in accordance with the analyser manufacturers’

requirements.

● Competence can be demonstrated by satisfactory

completion of the CPA1 ACS assessment, which covers

the use of electronic portable combustion gas analysers in

accordance with BS 7967, parts 1 to 4.

● Ensure that the gas analyser is set to the correct fuel

setting.

NOTE: Safe combustion can only be verified by measuring CO/

CO2 ratio. This must not exceed the value shown in the table on

the back page.

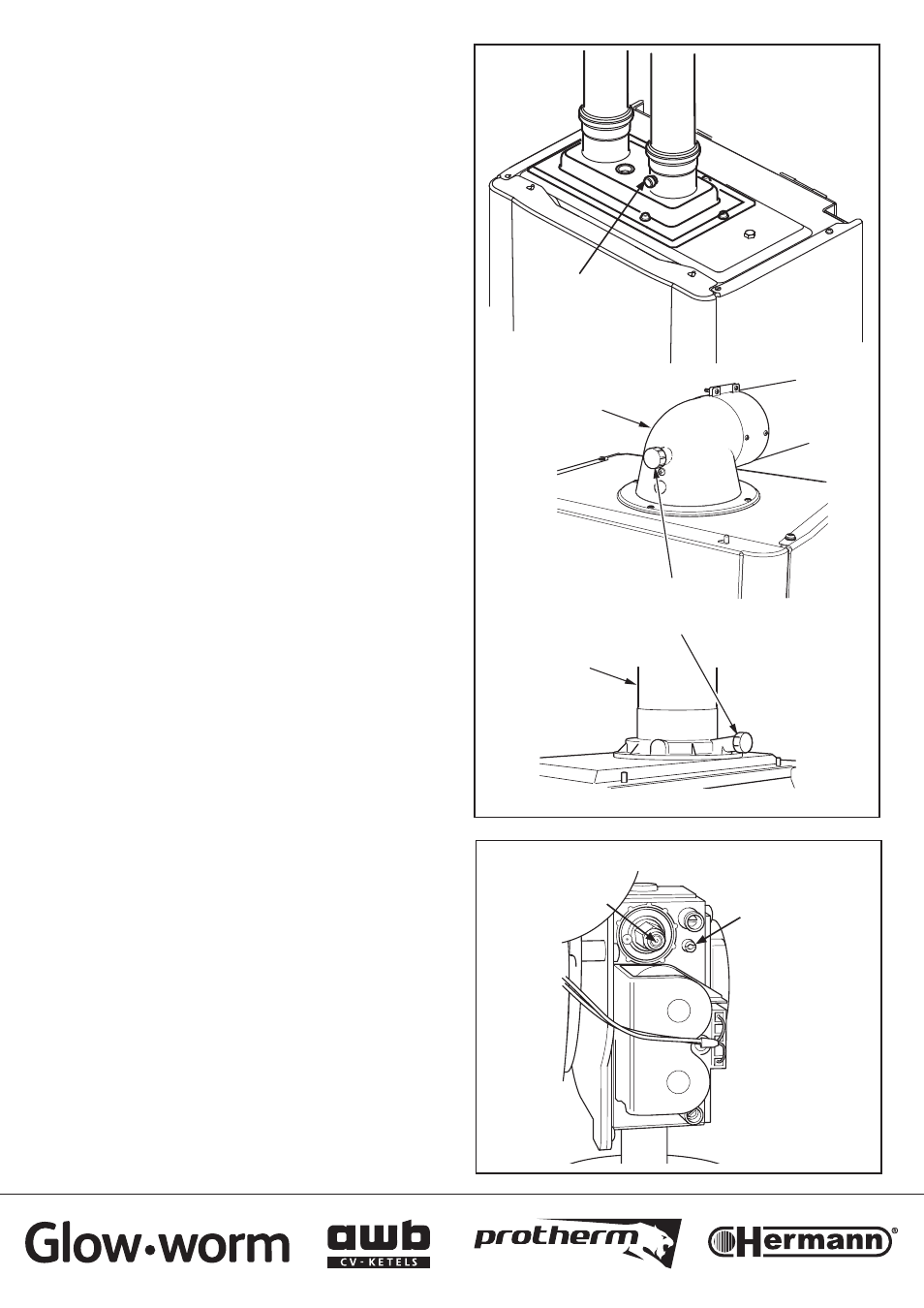

FLUE

ELBOW

COMBUSTION

ANALYSER

TEST POINT

FLUE

DUCT

Diagram 1

COMBUSTION

ANALYSER

TEST POINT

Diagram 2

OFFSET

ADJUSTMENT

2mm Allen Key

THROTTLE

Flat Bladed or

2mm Allen Key