10 commissioning – Glow-worm hxi and Gas Valve User Manual

Page 29

29

0020008153-05

10.1 Preliminaries - All Systems

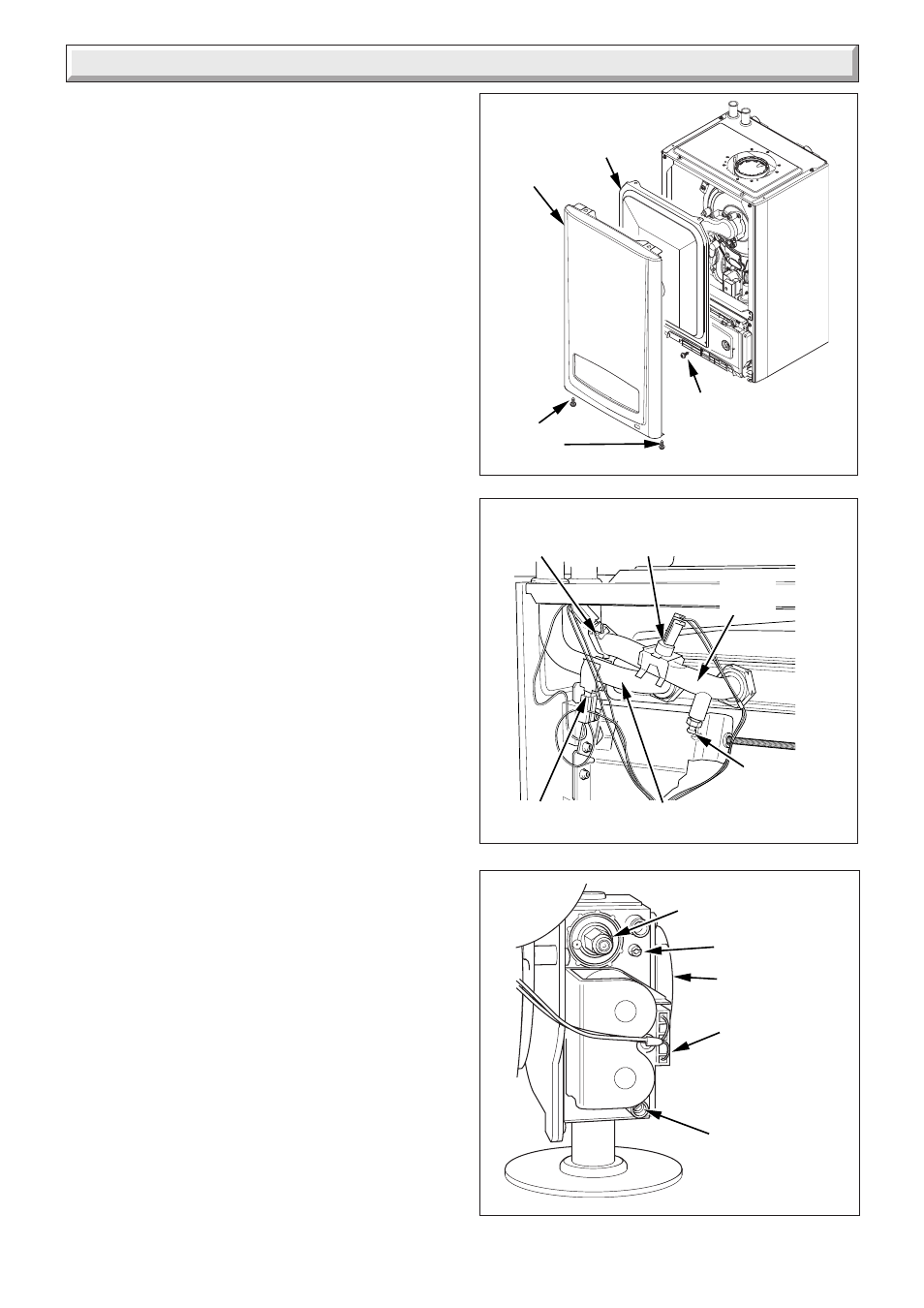

Remove inner casing panel, see diagram 10.1.

A competent person in accordance with the current issue of

BS6798 should carry out commissioning.

Make sure that the system has been thoroughly flushed out with

cold water.

Refill the system with water, making sure that all the air is

properly vented from the system and pump, diagram 10.2

shows vent point.

Before operating the boiler check that all external controls are

calling for heat.

10.2 Sealed Systems

Fill the system until the pressure gauge registers the

recommended pressure. Clear any air locks and check for

leaks.

Release the cold water to the initial design pressure.

10.3 Preparation for Lighting

Isolate the boiler from the mains electrical supply.

Test for gas soundness and purge air from the gas supply. Turn

on the gas service cock, slot in line with the length of the valve,

see diagram 7.1.

10.4 Initial Lighting

The lighting procedure of the boiler is fully automated.

Check that all external controls are calling for heat. If an integral

programer is fitted check that it is correctly programmed and if

necessary overridden to provide heat.

Ensure that the water temperature control knob is turned OFF.

Turn on the mains electrical supply and the mains reset switch

to (I) on the controls fascia.

Turn the water temperature control knob to (I) MINIMUM.

The fan should start and after a few seconds the ignition will

commence

If the burner fails to light the fan will stop. Initially this may be due

to air in the gas supply line. The boiler will automatically have

three attempts at ignition.

If necessary turn the mains reset switch to the off position (O),

then back to the on position (I) and the boiler will restart.

After the boiler has lit, allow to warm at MINIMUM temperature

setting to purge any air from the system.

NOTE: If the appliance is operated above MINIMUM on initial

lighting, there is a possibility that the overheat stat will trip, this

is due to air in the system having not been purged. See diagram

10.2 for overheat thermostat/reset switch.

Once the system has been purged of air turn the central heating

knob to the desired temperature.

The appliance will then continue to fire until the user controls are

satisfied.

NOTE: After first power up the firing sequence for central

heating changes. After one minute stabilisation time the boiler

will ramp slowly to full rate rather than going immediately to full

rate. This is an adaptive feature to cope with small system

requirements.

10 Commissioning

Diagram 10.3

PRESSURE TEST

POINT

ELECTRICAL

PLUG

Diagram 10.2

VENT POINT

GAS

VALVE

THROTTLE

OFFSET

ADJUSTMENT

FLOW

THERMISTOR

RETURN

THERMISTOR

11404

12412

Diagram 10.1

INNER

CASING

PANEL

CASING

PANEL

12354

SECURING

SCREWS

SECURING

SCREWS (2 OFF)

RETURN

PIPE

OVERHEAT

THERMOSTAT /

RESET SWITCH

FLOW

PIPE