2 water systems, 3 flue and ventilation – Glow-worm Hideaway 40BF User Manual

Page 8

8

221691B

Diagram 2.2

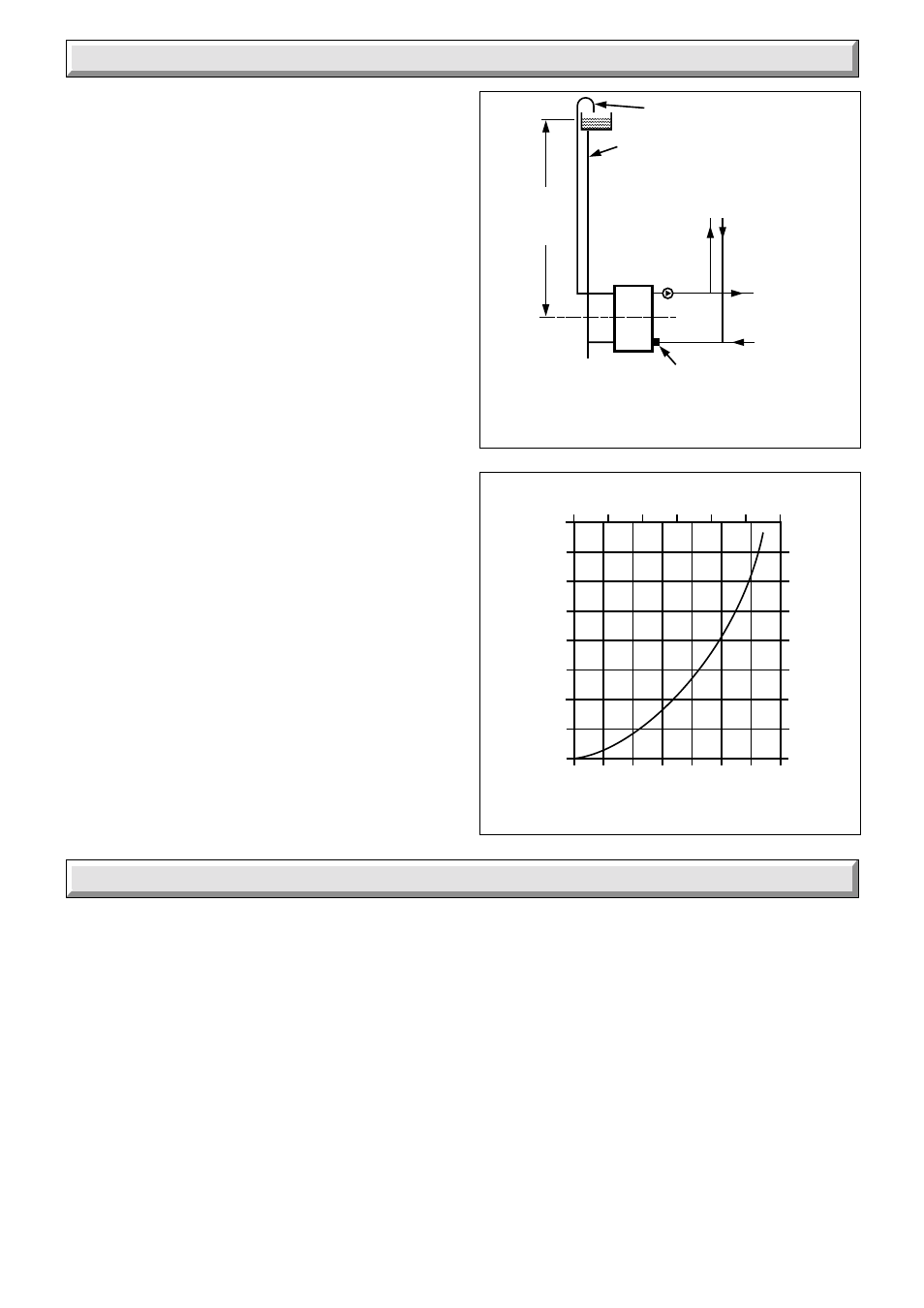

FULLY PUMPED SYSTEM

(DIAGRAMMATIC)

2 Water Systems

0870

1 metre

MIN.

27metres

MAX.

PUMP

To Heating

Circuit

TO INDIRECT

CYLINDER

22mm VENT

15mm

COLD FEED

Distributor tube in

pumped return

connection

BOILER

CL

DRAIN OFF

COCK

PRESSURE LOSS OF BOILER

Diagram 2.3

0872

600

500

400

300

200

100

0

12

8

4

0

0

4

8

12

16

20

24 28

FLOW RATE (LITRES/MINUTE)

WATER PRESSURE LOSS

(mm HEAD OF WATER)

WATER PRESSURE LOSS

(INCHES HEAD OF WATER)

24

16

800

32

28

20

700

0

1

2

3

4

5

6

FLOW RATE (GALLON/MINUTE)

2.3 Gravity Domestic and Pumped Heating

It is recommended that a cylinder thermostat is used to prevent

the stored water temperature becoming unnecessarily high

when the central heating pump is off.

The domestic primary flow and return must be 28mm o.d. The

installation must comply with the current issue of BS5546 and

BS6700, see diagram 2.1.

If the above conditions cannot be met, it is suggested that a fully

pumped system be used.

2.4 Pumped Heating and Hot Water

Where a single flow and return is taken from the boiler, a

minimum static head of 1metre (3ft3in) must be provided

between the water line of the feed tank and the centre of the

waterway, see diagram 2.2.

2.5 Circulation Pump

Normally the pump should be set to give a temperature difference

of 11

o

C (20

o

F) across the boiler. At the appropriate pumped flow

rate the pressure loss through the boiler can be found from the

graph, diagram 2.3.

Use a pump with integral valves or fit isolating valves as close

to the pump as possible.

Note: If the pump is to be fitted inside the boiler casing a heat

shield kit is required. Kit No. 425837.

2.6. Cylinder

For all systems supplying domestic hot water the cylinder must

be indirect.

2.7 Safety Valve

A safety valve need not be fitted to an open vented system.

2.8 Draining Tap

A draining tap must be provided at the lowest points of the

system which will allow the draining of the entire system,

including the boiler and hot water cylinder.

Draining taps should be to the current issue of BS2879.

3 Flue and Ventilation

3.1 Flue

Detailed recommendations for flues are given in the current

issue of BS5440 Part 1.

The boiler must be installed so that the flue terminal is exposed

to the external air. It is important that the position allows the free

flow of air across it at all times.

3.2 Terminal Positioning

The minimum acceptable spacings for the terminal to

obstructions, other terminals and ventilation openings are given

in diagram 3.1.

Car port or similar extensions of a roof only, or roof and one wall,

require special consideration with respect to openings, doors

and windows under the roof. Care is required in protecting the

roof if made from plastic sheeting. Seek further advice if the car

port consists of a roof and two or more walls from the local gas

undertaking.

Where the terminal is within 850mm (34in) below plastic guttering,

an aluminium shield 1.5metres (5ft) long should be fitted to the

underside and immediately beneath the guttering.

The air inlet and products outlet duct and the terminal of the

boiler must not be closer than 25mm (1in) to combustible

material.

3.3 Timber Frame Building

If the boiler is to be installed in a timber frame building it should

be fitted in accordance with the Institute of Gas Engineers

document IGE/UP/7/1998. If in doubt seek advice from the local

gas undertaking or Hepworth Heating Ltd.