6 electrical wiring – Glow-worm Hideaway 40BF User Manual

Page 14

14

221691B

6 Electrical Wiring

MAINS INLET

CONNECTOR

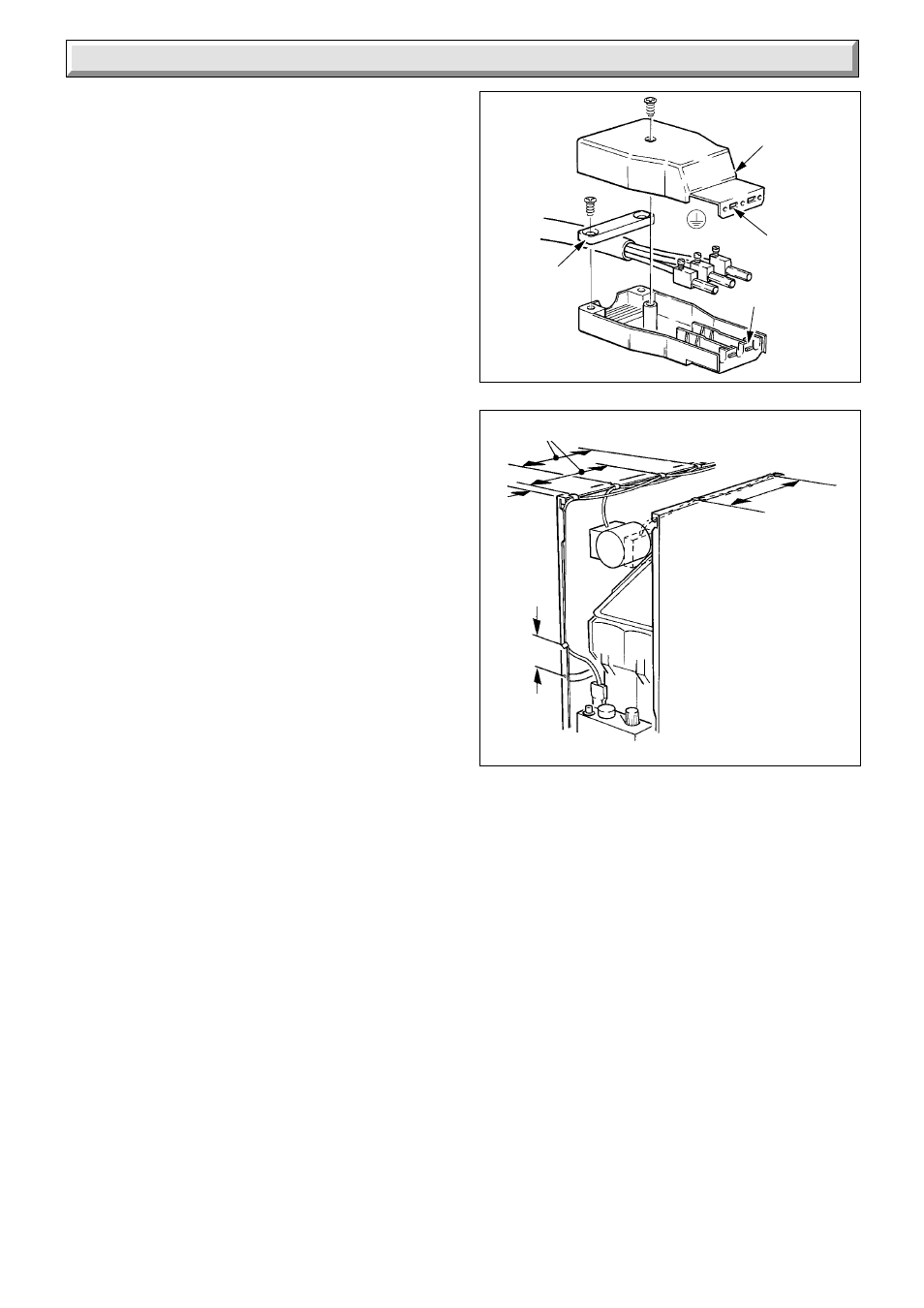

Diagram 6.1

CABLE CLIP POSITIONS

Diagram 6.2

0878

P

CB

25

(1 in.)

AP

AP

CB

P

0904

Fit 2 pump cable

clips at positions P

230

(9 in.)

Alternative pump cable

clips (if feed is on the

right hand side) at

positions AP

Fit 3 control

box feed cable

clips at positions

CB

CB

N

L

CABLE

CLAMP

COVER

SLOTS

LUGS

230 (9 in.)

60

(2

3

/

8

in.)

E

6.1 Control Box Cable Connection

Warning. This boiler must be earthed.

Remove the screw and cover from the mains inlet connector,

supplied loose, see diagram 6.1.

Using heat resistant flexible cable of suitable length and rating

as in Section 1.6, connect the three cables to the required

terminals in the connector. Secure the outer sheathing with the

cable clamp.

Engage slots and lugs, replace cover and secure with screw.

Connect the mains inlet connector to the control box and use

three of the cable clips, supplied loose, pushed on to the edge

of the left hand panel in positions “CB” as shown in diagram 6.2

to make sure the cable does not make contact with any hot

surfaces.

6.2 Pump Cable Connection

Heat resistant cable with a rating as stated in Section 1.6 must

be used for all wiring near the boiler, including the pump if within

the boiler casing.

Support pump cable away from hot surfaces if within the boiler

casing by pushing two cable clips, supplied loose, on to the top

edge of one side panel, shown as “P” or “AP” in diagram 6.2.

6.3 System Controls

The electrical installation must be made according to the

current issue of BS7671.

The electrical isolator must isolate both the boiler and any

system controls.

6.4 Testing

Checks to ensure electrical safety should be carried out by a

competent person.

In the event of an electrical fault after installation of the boiler,

preliminary system checks must be carried out, that is, earth

continuity, polarity and resistance to earth, as described in the

British Gas Multimeter Instruction Book or similar publication.