1 general data, 2 water systems – Glow-worm Hideaway 40BF User Manual

Page 7

7

221691B

FRONT CLEARANCE

Diagram 1.5

0906

700 (27

1/

2

in.)

BOILER

WALL OR

FIXTURE

1 General Data

The base temperature is within the requirements of the current

issue of BS5258. The boiler may stand on a wooden floor but

a metal base plate is required to protect plastic tiles and similar

floor coverings.

When the boiler is to be installed level with work surfaces and

the like, minimum clearances should be provided as shown in

diagram 1.3. Work tops which overhang the cupboard sides,

almost in contact with the casing top, require a larger minimum

air gap. Flush sided fixtures require the same overall minimum

space but can have a reduced air gap on one side.

Boilers to be installed under work tops or fixtures, with or without

the casing top fitted should be positioned to provide minimum

clearances as shown in diagram 1.4. To facilitate minimum

clearances it may be necessary to modify kitchen units and

fixtures.

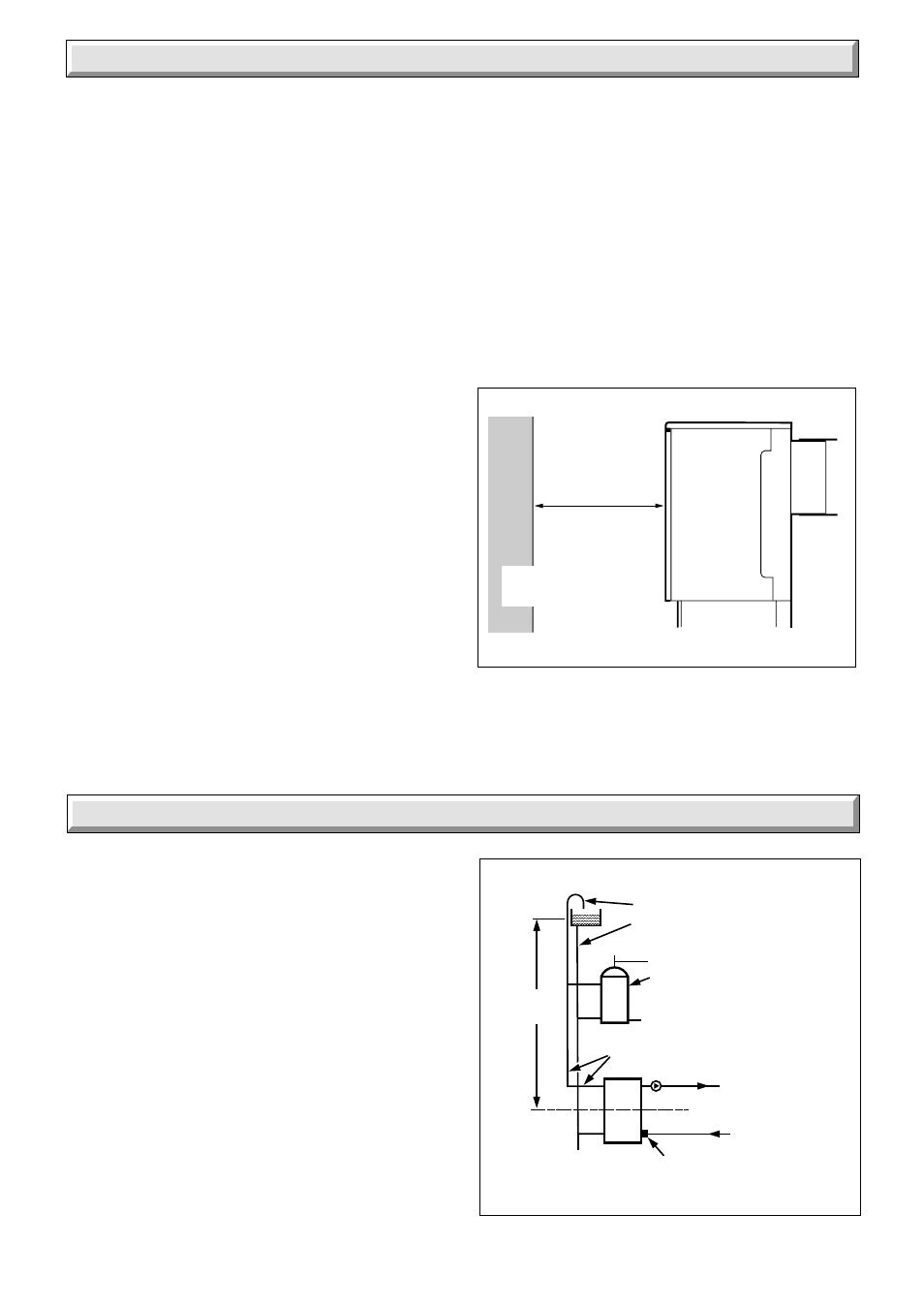

A front access clearance should be provided as shown in

diagram 1.5.

The boiler may be installed in any room, although particular

attention is drawn to the requirements of BS7671 with respect

to the installation of a boiler in a room containing a bath or

shower. Any electrical switch should be so positioned that it

cannot be touched by a person using the bath or shower. The

electrical provisions of the Building Standards (Scotland)

Regulations apply to such installations in Scotland.

Where the installation of the boiler will be in an unusual location,

special procedures are necessary the current issue of BS6798

gives detailed guidance on this aspect.

A compartment used to enclose the boiler must be designed

and constructed specifically for this purpose. An existing

cupboard or compartment modified for the purpose may be

used. Details of essential features of cupboard or compartment

design are given in the current issue of BS6798.

2 Water Systems

2.1 Water Pressure Head

The boiler shall only be connected to a cistern water supply with

a minimum head of 1metre (3ft3in) and a maximum head of

27metres (90ft) which has an open vent in the system.

The working pressure must be within the range 0.1bar to 2.7bar

(1.3 to 39lbftin

2

).

The boiler MUST NOT be connected to a sealed water system.

2.2 Inhibitor

Attention is drawn to the current issue of BS5449 and BS7593

on the use of inhibitors in central heating systems.

If an inhibitor is to be used in the system, contact should be

made with the inhibitor manufacturers so that they can

recommend their most suitable product.

When using in an existing system take special care to drain the

entire system, including the radiators, then thoroughly cleaned

out before fitting the boiler whether or not adding an inhibitor.

Diagram 2.1

0869

27metre

Max.

PUMP

To Heating

Circuit

INDIRECT

CYLINDER

22mm VENT

15mm COLD FEED

REFER TO BS 5546

28mm

Distributor tube in

pumped return

connection

BOILER

CL

DRAIN OFF

COCK

1.8 Heating System Controls

The heating system should have installed: a programmer and

room thermostat controlling the boiler.

Thermostatic radiator valves may be installed in addition to the

room thermostat.

Note: For further information, see The Building Regulations

1991 - Conservation of fuel and power, 1995 edition - Appendix

G, table 4b.