4 installation – Glow-worm Hideaway 40BF User Manual

Page 11

11

221691B

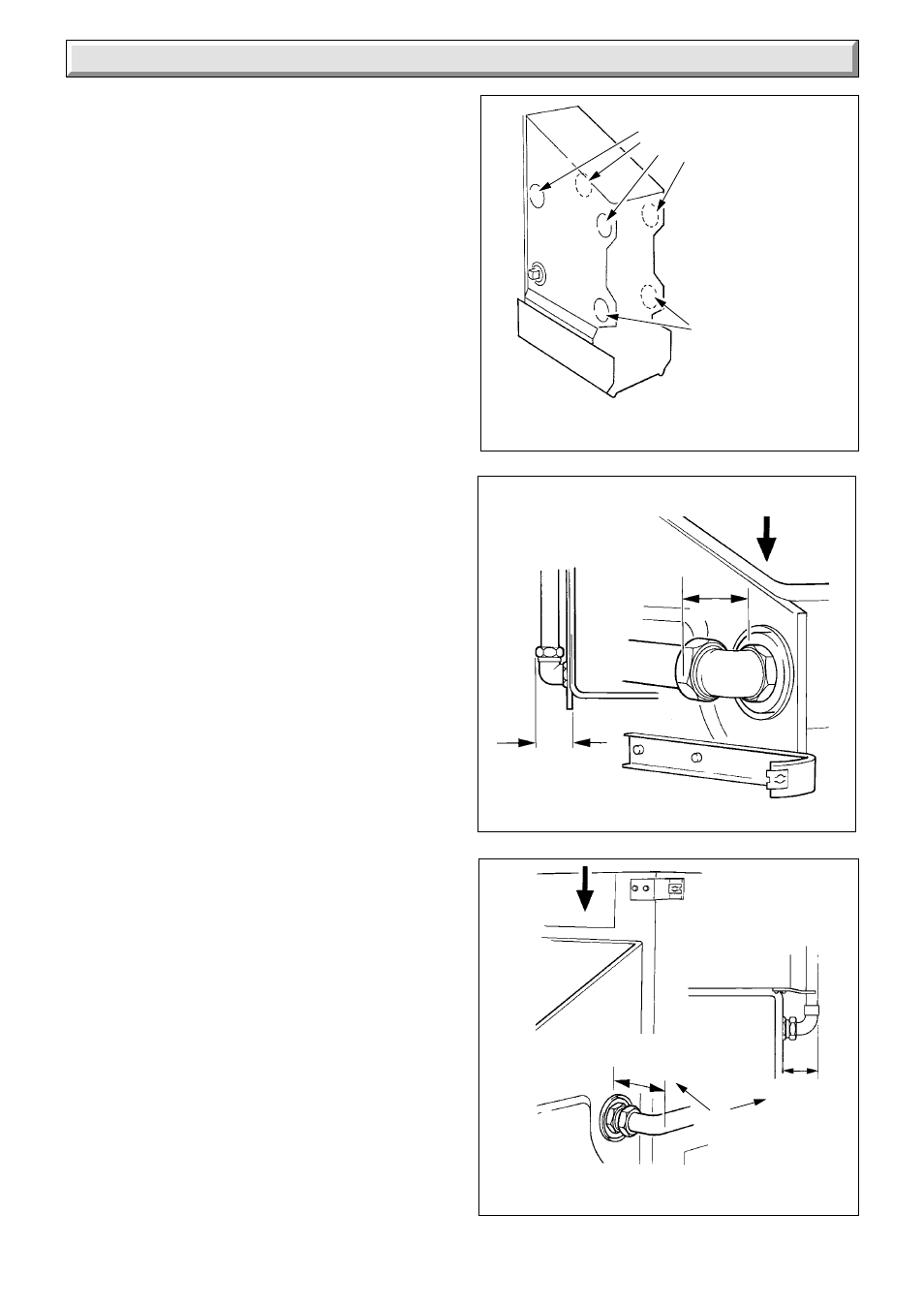

Diagram 4.4

WATER CONNECTIONS FULLY

PUMPED SYSTEMS

4 Installation

0874

ALTERNATIVE

FLOW

POSITIONS

ALTERNATIVE

RETURN

POSITIONS

With distributor

tube (not shown)

4.6 Pipework

When the front tappings are used, it is essential that any

pipework of fittings do not project more than shown in diagram

4.5.

When using a rear tapping with Rc (1in BSP) fitting for 28mm od

pipework, it is recommended that a short nipple and an R thread

(BSP) to copper elbow is used. If the pipework is required to

run back to the wall, make sure that it will clear the boiler air duct

and, if working to minimum clearance, does not stick out too far

from the boiler, see diagram 4.6.

Do not route any pipework, water or gas, across the front of the

thermostat pocket, controls or combustion chamber cover.

The gas pipework must be along the right hand side of the boiler.

4.7 Balanced Flue Terminal

(Standard and short flue)

Mark out and cut a hole through the wall where the boiler is to

be installed, to the dimensions shown in diagram 4.7, after

checking that sufficient clearances will be left around the boiler

as described in Section 1.7.

Place the boiler in position. The balanced flue ducting will

project into the prepared hole in the wall.

Make a good seal around the boiler air duct on the inside wall.

Take the balanced flue assembly from its carton and remove the

four screws to release the outer baffle, see diagram 4.8.

Remove the four outer wire guards then pull off the inner baffle

and flue duct assembly.

Place the air duct assembly into the hole in the wall from the

outside, engaging it around the air duct on the boiler and sliding

it until the wall plate contacts the outer wall surface.

Seal the joint in the air ducts with the yellow tape provided. Tape

four pieces into the four inside corners, followed by four along

the joints, overlapping the corner pieces, to make a good seal.

Allow a minimum of 20mm (

3

/

4

in) overlap of ductings.

Cement around the wall plate to make good and weatherproof.

Refit the inner baffle and flue duct assembly, sealing the joint

with the heat resistant semi-transparent tape provided.

Refit wire guards, outer baffle and secure with screws.

Diagram 4.5

Diagram 4.6

PIPEWORK CASING

CLEARANCES

REAR CONNECTION

PIPEWORK (28mm)

BOILER

57 MAX.

(2

1

/

4

in.)

'A'

VIEW ON ARROW 'A'

57 MAX.

(2

1

/

4

in.)

1524

1525

57 MAX.

(2

1

/

4

in.)

VIEW ON

ARROW 'B'

'B'

BOILER

57 MAX.

(2

1

/

4

in.)

FOR

MINIMUM

CLEARANCE