7 fault finding, 1 fault finding – Glow-worm Clearly Heat Recovery User Manual

Page 24

24

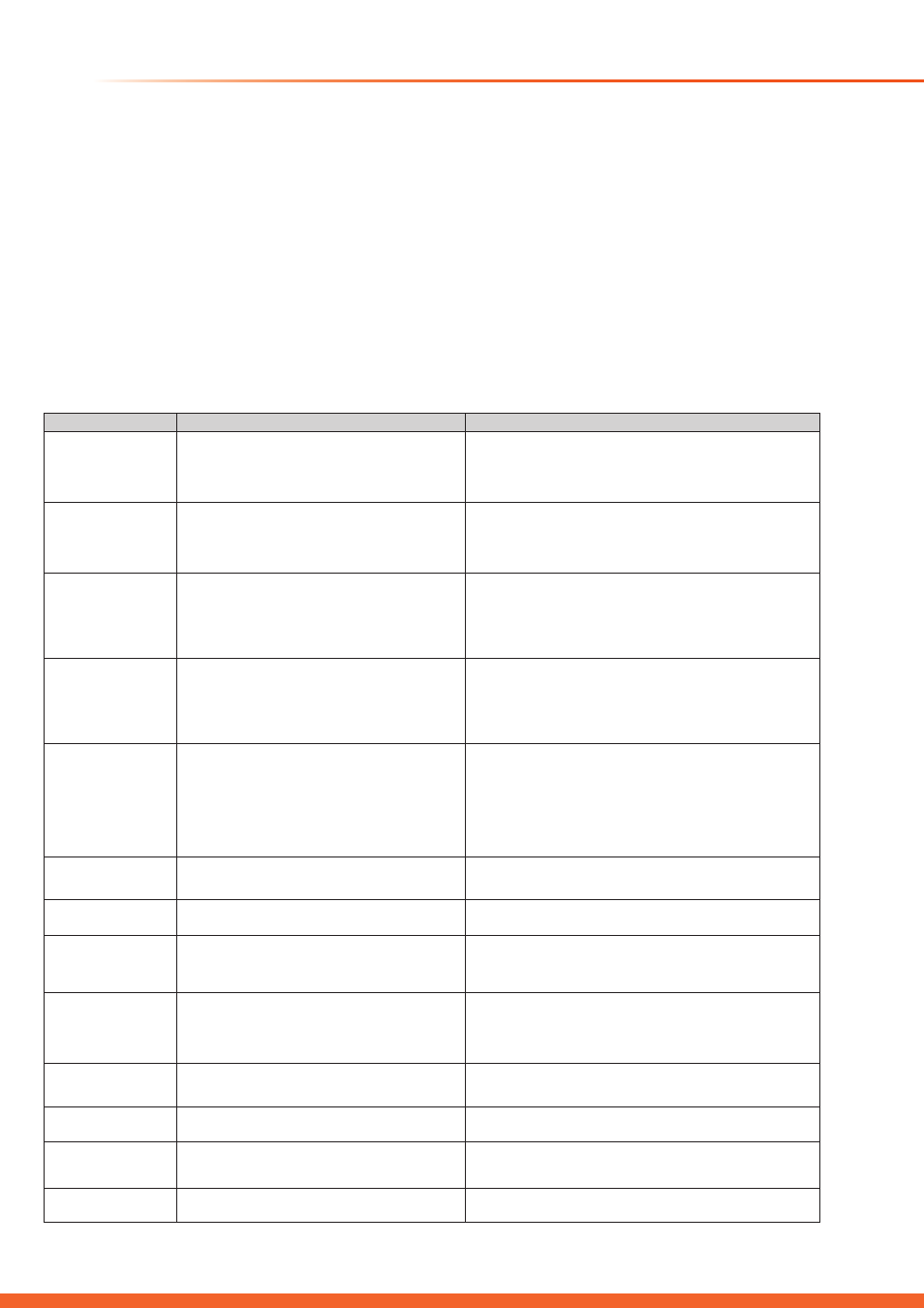

7 Fault Finding

Fault

Cause

Remedy

The unit does not

operate

Temporary interruption of the mains voltage supply

or no supply at all. Power supply circuit breaker

tripped. Electricity disconnector was activated.

Fuse F4 in the unit is defective.

After a mains failure the unit automatically restarts once the

mains voltage is re-established. Re-set circuit breaker in mains

distribution board. Check that all cables are properly

connected and undamaged. If necessary, replace the fuse F4

on the PCB.

Unit operation is very

loud even at the

minimum fan speed

No silencers in the fresh air and exhaust air ducts.

Wrong silencers, or silencers are too short. Filters

are extremely soiled.

Ventilators are defective or heavily soiled.

Mount additional silencers in accordance with the system

design.

Reduce the air quantity to the minimum fan stage. Clean or

replace filters.

Replace or clean ventilators, check the reason of soiling.

None or insufficient

fresh air supply

Filters are extremely soiled.

Fresh air valves/grilles closed too much.

Exhaust air or fresh air ducts obstructed.

Fresh air input louvre too small.

Incorrect wiring.

Fan defective.

Clean the filter.

Open the fresh air valves/grilles. Adjust the system again.

Clean the exhaust air and fresh air ducts.

Fit a larger louvre.

Check the wiring.

Replace the fan if necessary.

No or insufficient

exhaust air flow

(i.e. in the bathroom

the mirror stays

fogged up)

Filters are extremely soiled.

Exhaust air valves closed too much.

Exhaust air or fresh air ducts obstructed.

Fresh air input louvre too small.

Incorrect wiring.

Fan defective.

Clean the filter.

Open the exhaust air valves. Adjust the system again.

Clean the exhaust air and fresh air ducts.

Fit a larger louvre.

Check the wiring.

Replace the fan if necessary.

Bypass summer mode

does not work

Bypass function not activated or set days for

summer mode expired.

Incorrect positioning of the temperature sensor.

Flap position and/or motor for bypass defective.

Defective bypass motor wiring.

In the programming level of the remote control, set or activate

the bypass function.

Correctly position the temperature sensor.

Check the flap position and the motor and, if required, replace

them.

Check that the plug to the flap motor is correctly positioned.

Check in the Service/Diagnostics menu whether the sensors

are detected at the remote control. See section 6

Noise in the

condensation water

drain trap

Drain trap incorrectly connected.

Connect the drain in accordance with section 4.3.

Water dripping from

the unit

Exhaust air and fresh air ducts are not vapour-

sealed.

Insulate exhaust air and fresh air ducts, make ducts air-tight or

use specially insulated pipes.

Fresh air too cold

Exhaust air and fresh air flows not balanced.

Wrong flap position and bypass motor defective.

Adjust the unit in accordance with section 5.8.

Check the flap and motor,

Clean the flap and bracket,

if necessary, replace the bypass.

No fresh air or

exhaust air (only one

fan running)

Frost protection activated.

With outside temperatures below -7 °C, correct

operation.

The frost protection sensor will not work at a

discharge air temperature above 3 °C.

Check the resistance of the frost protection sensor based on

table, “Resistance Values of the Temperature Sensor“.

If necessary, replace the frost protection sensor.

Odours from the

kitchen/WC enter into

other rooms

Outlets for fresh air and exhaust air are too close

to each other.

Extend the distance between the outlets for fresh air and

exhaust air. We recommend to position these junctions in

different parts of the roof.

Sound transmitted

between the rooms

No crosstalk absorbers mounted.

Additionally install crosstalk absorbers.

Adjust the unit in accordance with section 5.8.

Planned air flow not

reached at the start-up

System is not air-tight.

Seal all pipe connections properly if necessary.

Noise in the unit after

replacing the fan.

Wrong mounting of the fans.

Check the correct positioning of the fans.

7.1 Fault Finding

The faults listed below may only be rectified by a

competent

person approved at the time by the Health and Safety

Executive.

The following checks should be performed before proceeding

onto specific diagnostics:

•

Check the external electrical supply to the boiler is on and

a supply of 230V is present at the ‘L’ and ‘N’ terminals on

the installer interface, refer to section 11.4 for access and

diagram 14.4.

•

Check the electrical installation and unit, carry out tests for

earth continuity, polarity, short circuit and resistance to earth,

using a suitable multimeter.

•

Check that all external controls are on.

•

Check the functional flow diagram, 14.5.