Dillon case gages – Dillon Precision Case Preparation Tools User Manual

Page 9

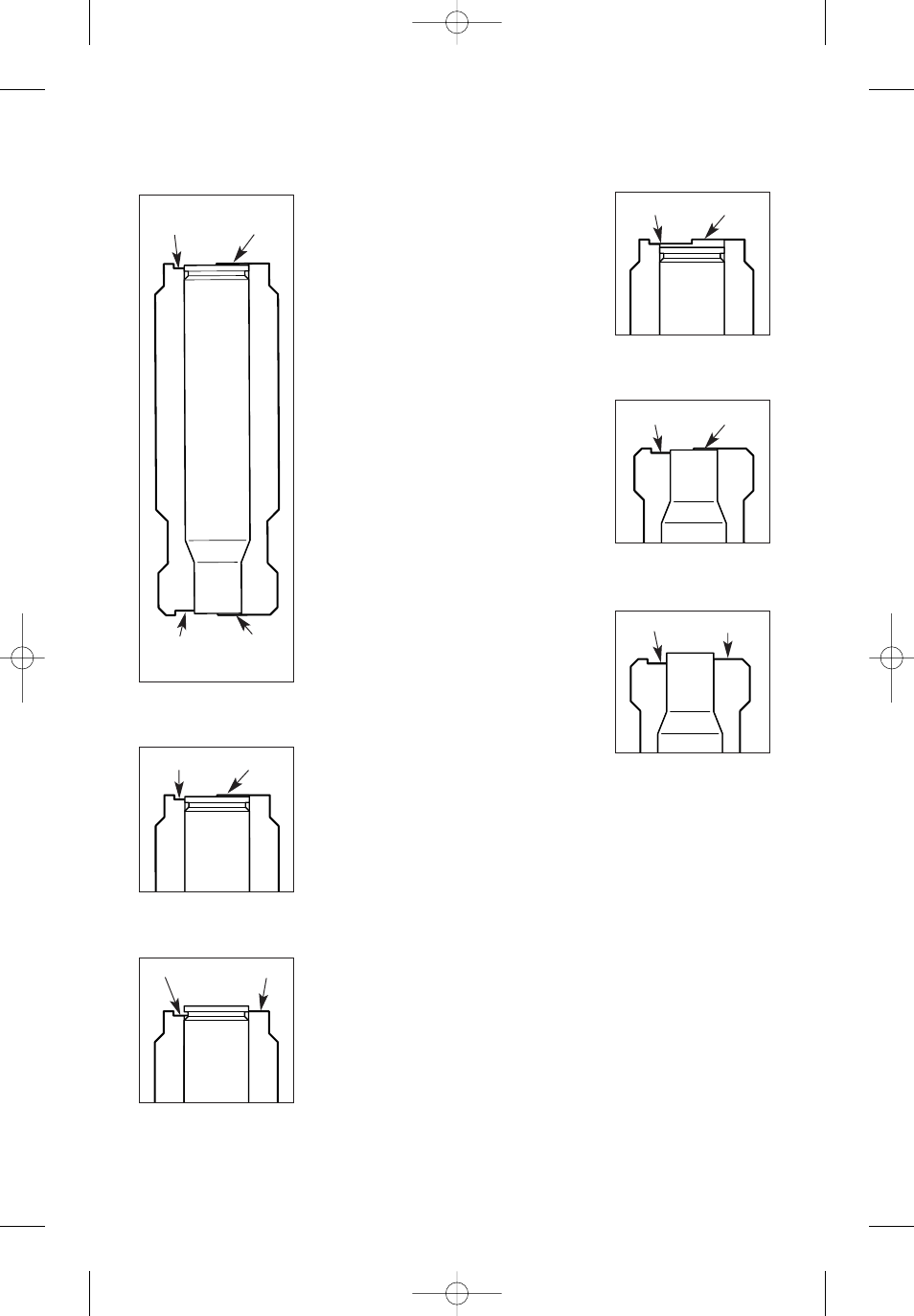

How to use the Case Gage:

The way the case gage works is

this: Once you’ve made a prelimi-

nary adjustment to your sizing die

drop the sized case all the way into

the case gage, Fig 1. Look at the

base of the case.

If the base of the case is below

the high step (see “B” Fig 2) and

above the low step (see “A” Fig 2)

then the sizing die is properly

adjusted. If the base of the case is

above the high step Fig 3, then you

will need to adjust the sizing die

down by turning it clockwise.

If the base at the case is below

low step Fig 4, then the sizing die

is adjusted down too far and needs

to be backed out by turning it

counter-clockwise (Note: this case

should be thrown away).

Once the sizing die is properly

adjusted, drop the properly sized

case back into the case gage and

look at the mouth of the case, Fig

5. If the case mouth is below the

high step (see “C” Fig 5) and above

the low step (see “D” Fig 5) then

the case is the proper length and

will not need to be trimmed. If the

case mouth is above the high step

Fig 6, then the case mouth needs to

be trimmed in order to reduce the

overall length of the case.

If you find that your cases need

to be trimmed, Dillon Precision

offers two types of case trimmers.

7

Dillon Case Gages

Figs 72 & 73

Fig 74

Fig 75

Fig 76

Fig 77

Figs 72 & 73

Fig 74

Fig 75

Fig 76

Fig 77

A B

Fig 3

A B

A

low step

B

high step

For expert assistance or to place an order, call (800) 223-4570

Fig 2

D

high step

C

low step

Fig 1

Fig 4

Fig 5

Fig 6

C D

C D

A B

Accessory Manual, May 2007 5/22/07 8:27 AM Page 10