Dillon case gages, cont – Dillon Precision Case Preparation Tools User Manual

Page 10

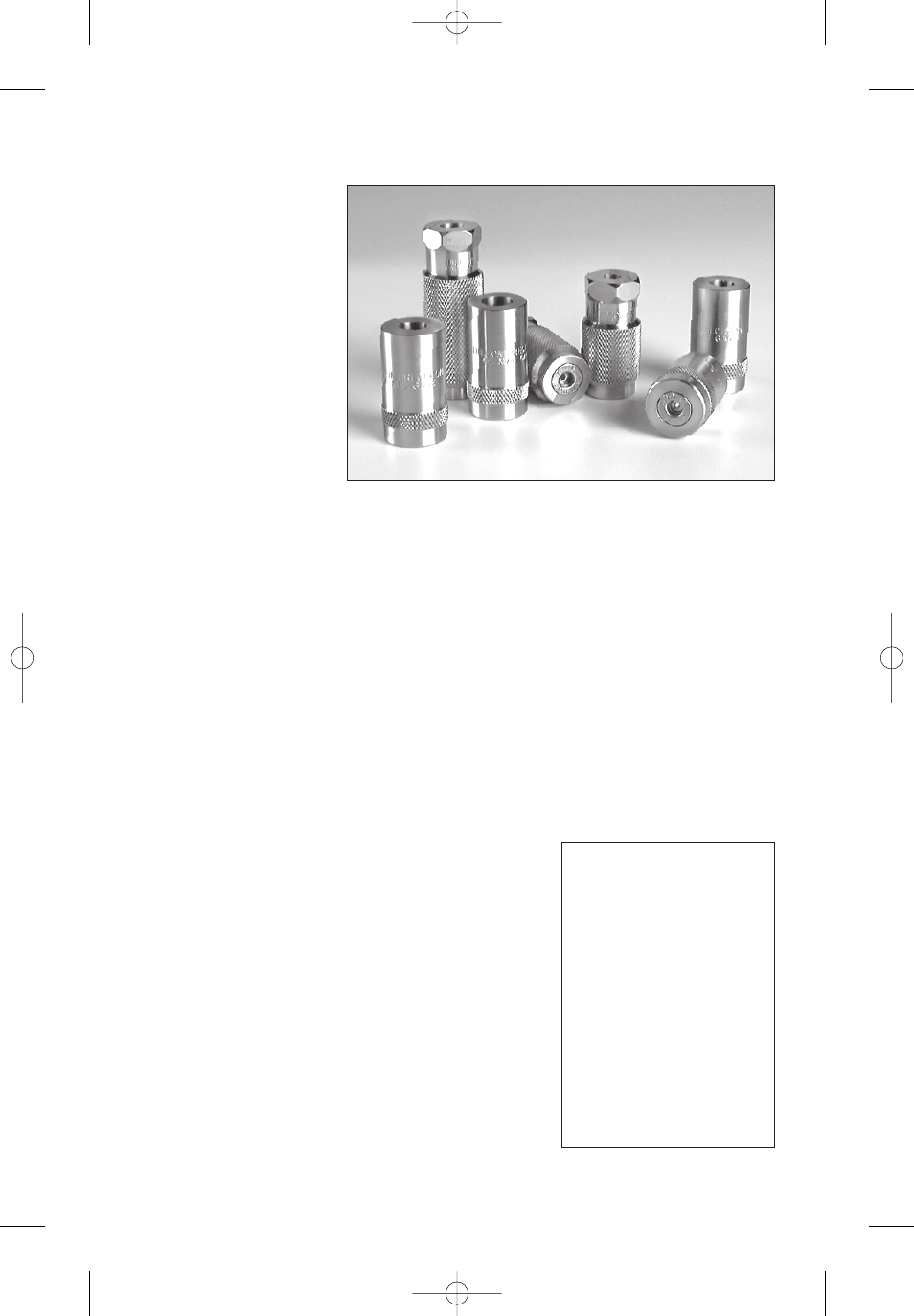

Dillon Case Gages, cont…

NOTE: Before

inserting any case into

a case gage, make sure

it is wiped clean of any

lubricant. Otherwise,

the lubricant will accu-

mulate inside the case

gage and cause it to

become coated with

grit and dust. This will

cause the case gage to

give inaccurate read-

ings. Always refer to a

reliable loading manual

for case dimensions.

RIFLE case gages have “steps” on the top and base. If a case is properly

trimmed and the shoulder setting is correct, the case should fall between the

high and low steps. These two settings are accomplished at different stages of

reloading.

Shoulder setting is done at station one of your loading machine. When a

case has a proper shoulder setting it will fall between the high and low steps

at the BASE of the case gage. If it falls below the low step, you need to raise

your sizing die up in 1/8 turn increments until the proper setting is achieved.

If the case is above the high step, you need to lower the sizing die.

Overall length, or OAL, is done while trimming fired rifle cases back down

to size. Insert a CLEAN case into the gage and set it on a clean, flat surface. If

the case is trimmed properly, the mouth of the case will be between the high

and low steps at the TOP of the gage. If the mouth of the case is above the

high step, you need to turn your trim motor down in small increments until

the proper OAL is reached. If the rim is below the low step, you need to raise

the trim motor. Refer to trimmer instructions.

PISTOL case gages do not have the steps

mentioned in the rifle gage section. The pistol

gage is used to determine overall length and

case diameter. Designed to maximum SAAMI

cartridge length and minimum chamber diame-

ter. OAL is achieved by seating the bullet to the

proper depth at station three of your loading

machine.

Insert a completed round into the gage and set

it on a clean, flat surface. If the bullet extends

from the top of the gage, the round is too long. To

seat the bullet deeper into the case, adjust your

seating die down in 1/8 turn increments until the

proper OAL is achieved.

.380 ACP

#15160

9 mm

#15161

.38 Super

#15158

.38 Special

#15159

.357 Mag.

#15163

.40 S&W

#15164

10 mm

#15162

.44 Mag.

#15165

.45 ACP

#15166

.45 Colt

#15167

.223

#13254

.308

#12867

.30-06

#12679

8

For expert assistance or to place an order, call (800) 223-4570

Accessory Manual, May 2007 5/22/07 8:27 AM Page 11