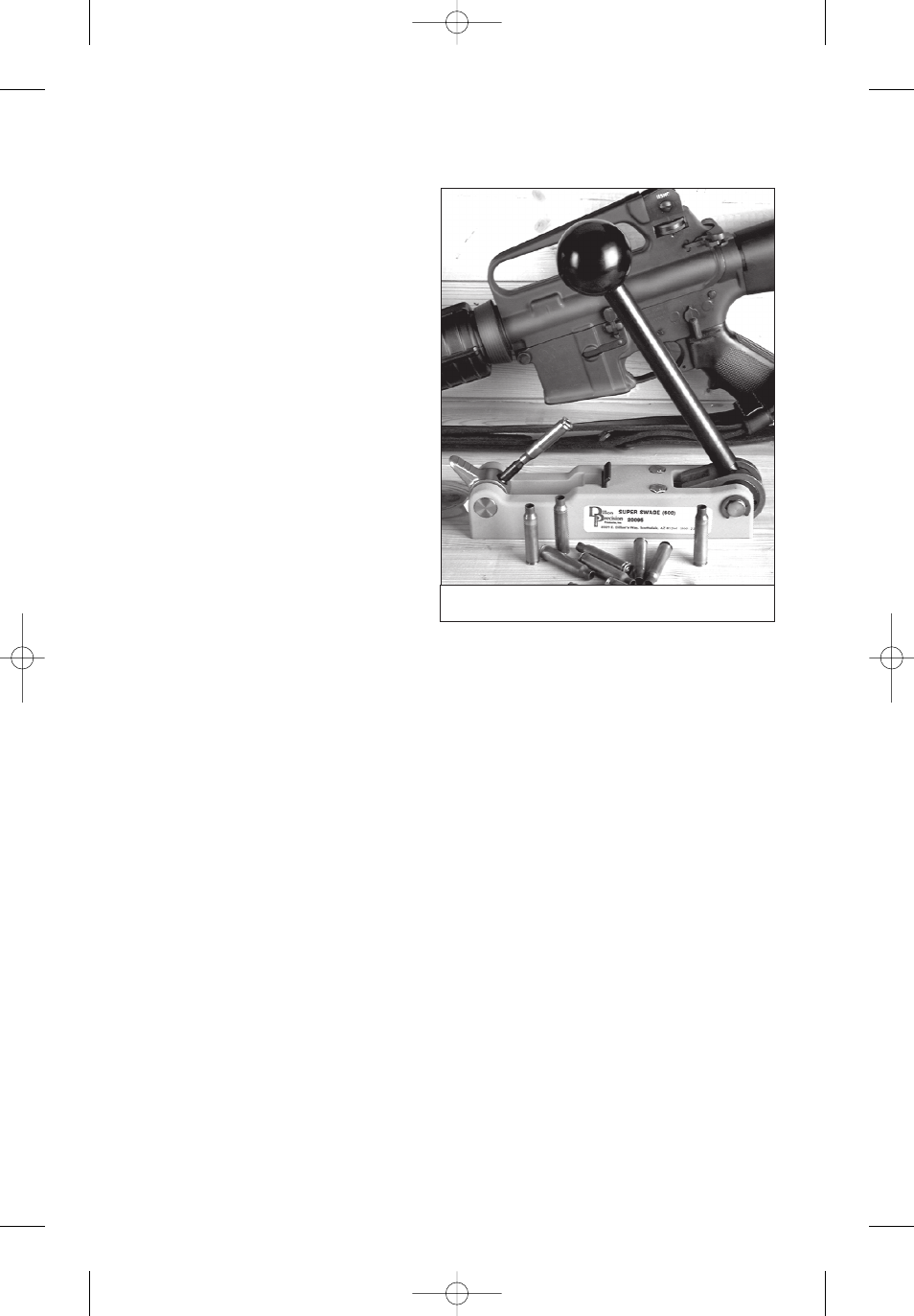

Dillon ss-600 super swager – Dillon Precision Case Preparation Tools User Manual

Page 7

5

For expert assistance or to place an order, call (800) 223-4570

Most military brass has a

crimped primer pocket and there-

fore requires swaging. The crimp

must be removed prior to reprim-

ing and reloading the case.

TO OPERATE: First make sure

all of your brass has been

deprimed.

Use the proper diameter case

locator rod. The unit comes with

the .223 rod installed. The larger

rods are for .30 cal, .38 and 9

mm. For .45 ACP, use the bushing

(not pictured) over the .30 caliber

rod.

Use the proper swage rod.

The smaller primer swage rod is

installed at the factory. (See page

6 for parts identification.)

To change swage rods:

Pry off an “E” clip from either side of the eccentric pin.

Slide the eccentric pin out and remove the handle/swage rod assembly.

Using a pencil or similar object, push out the toggle dowel pin.

Put a light coating of grease over the entire surface of the proper size

swage rod and re-assemble. When re-assembling the unit, be sure the

eccentric pin is on top of the handle in the eccentric, otherwise you won’t

be able to make a complete stroke.

Now set a case on the locator rod. Screw the locator rod in or out so

that the case goes down without hitting the back-up plate.

Slowly push the handle down and move the case so that the tip of the

swage rod enters the primer pocket.

Leave the swage rod in the primer pocket and lock the set screw on the

right side of the swager unit. This locks the location of the flat block. The flat

block sets the alignment of the primer pocket with the swage rod. Failure to

do this will ruin your case and may damage the swager itself.

Adjustment for the proper amount of swage is done by trial and error.

Not enough swage and the primers won’t seat fully. Too much swage will

stress the unit, possibly bending the locator rod.

Continued…

Dillon SS-600 Super Swager

SS-600 Super Swager, #20095

Accessory Manual, May 2007 5/22/07 8:27 AM Page 8