Dillon ss-600 super swage – Dillon Precision Case Preparation Tools User Manual

Page 8

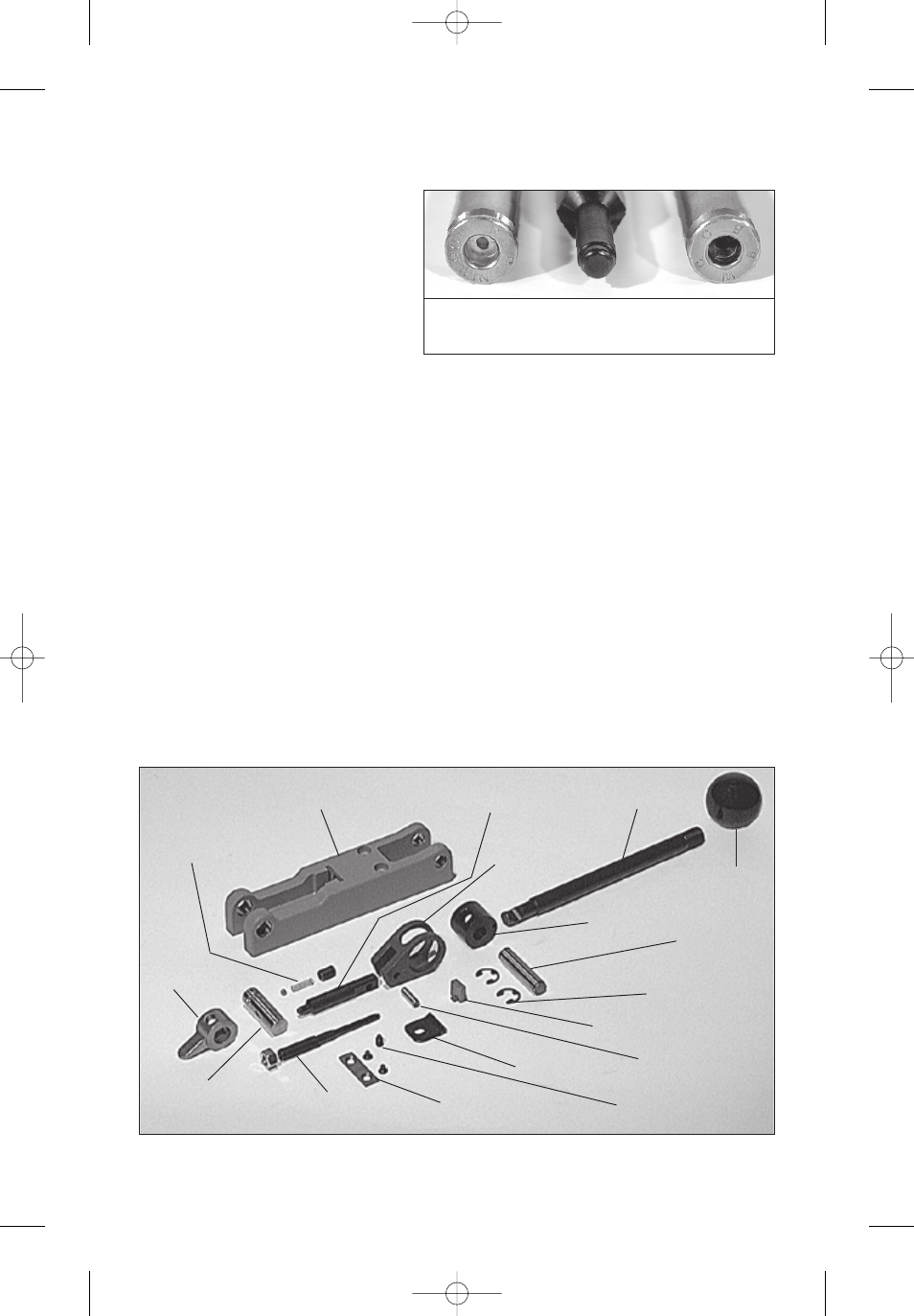

Detent Set Screw,

Detent Spring,

and Detent Ball.

Swager

Body

Swage Rod

(Large Rod Pictured)

Swager

Handle

Toggle

Knob

Eccentric

Eccentric Pin

E-clips

Flat Block

Toggle Dowel Pin

Back-up Plate

Flat Block Set Screw

Cover and Cover Screws

Case Locator Rod

(Small Rod Pictured)

Lever

Lever Pin

For expert assistance or to place an order, call (800) 223-4570

Dillon SS-600 Super Swage

A properly swaged pocket

should have a smooth radius

(see photograph B). Set the

locator rod for minimal swage

and swage a case. Examine the

edge of the primer pocket to be

sure it is smooth, then seat a

primer in it. Repeat this process

until enough swage is achieved to seat a primer easily.

NOTE: Re-adjustment of the locator rod may be required when swag-

ing brass from different manufacturers or different lots due to different case

webbing.

When changing calibers, the flat block will need to be re-adjusted,

.223 has a different case diameter than 9mm, etc. So repeat the steps nec-

essary for proper adjustment.

SPECIAL NOTE FOR 38 SUPER BRASS: Whenever it becomes neces-

sary to swage 38 super brass that has been hot-loaded, be sure to select a

case that is brand new when making adjustments. These cases have as

much primer pocket radius as you would ever want, so adjust your case

locator rod with a brand new case and then try some fired/deprimed

cases.

IMPORTANT: When mounting the Super Swager to your loading

bench, make sure that the handle can extend below the edge of the

bench. This is necessary to achieve a complete stroke.

6

Photo “B”: The case on the left shows a

properly swaged primer pocket.

Accessory Manual, May 2007 5/22/07 8:27 AM Page 9