Bolens 247.29773 User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

3. Keep your engine CLEAN. Wipe off all spilled

fuel and oil. Keep the engine clean of foreign

matter and be sure the cooling fins on the

cylinder are kept clean to permit proper air

circulation. You must REMEMBER that this is

an air cooled engine and free flow of air is

essential to proper engine performance and

life.

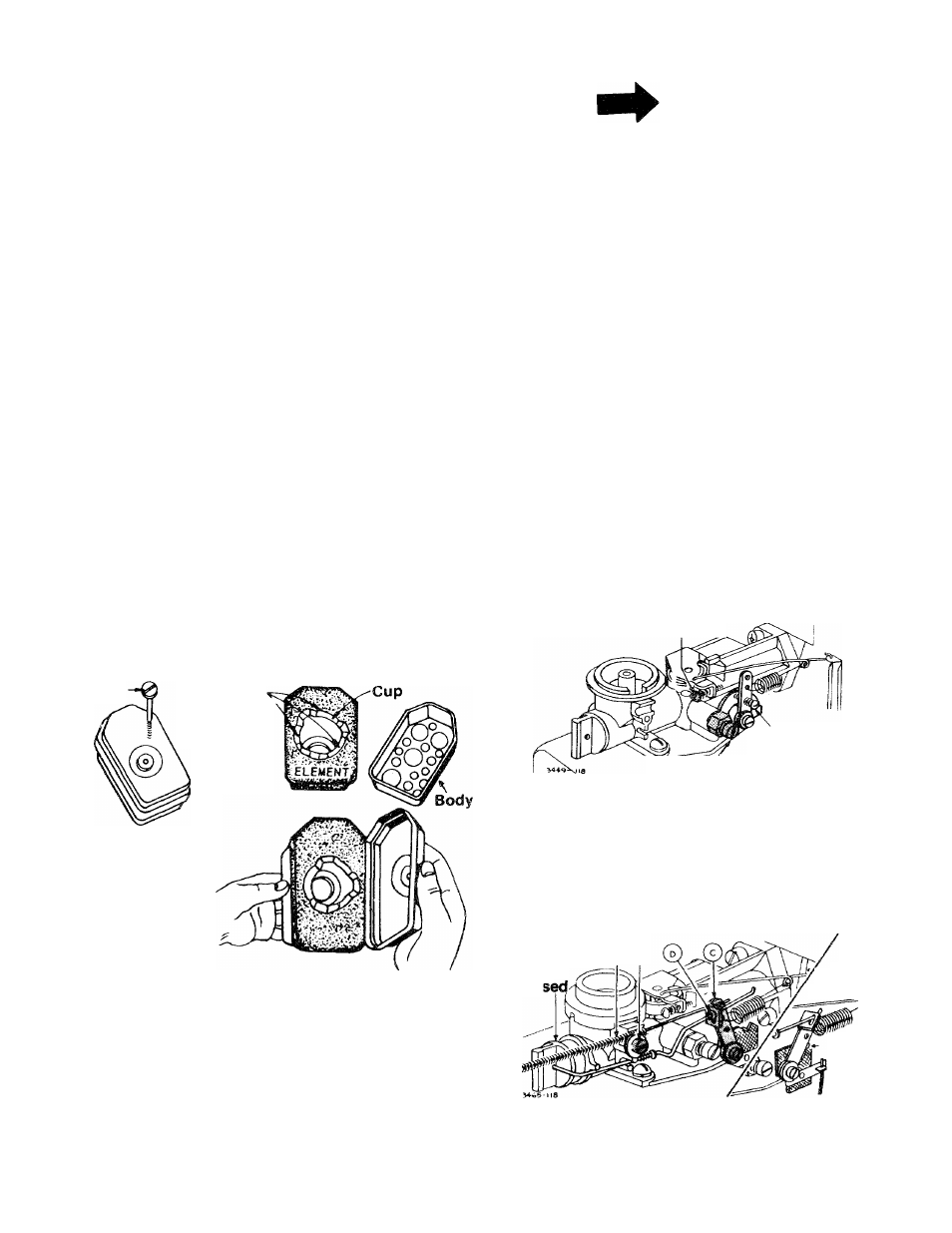

4. You must SERVICE YOUR AIR CLEANER. The

air cleaner prevents damaging dirt, dust, etc.

from entering the carburetor and being forced

into the engine and is important to engine life

and performance.

To remove air cleaner;

A. Remove screw.

B. Remove air cleaner carefuly to prevent dirt

from entering carburetor.

C. Take air cleaner apart.

D. Wash element in detergent and solution by

squeezing similar to a sponge.

E. Wrap foam in cloth and squeeze dry.

F. Coat element with two tablespoons of engine

oil, squeeze to distribute and remove excess

oil. See figure 28.

G. Wipe air cleaner body with same solution to

remove excess oil.

H. Reassemble (see figure 28) by inserting ele

ment into body and snapping cover into place,

fasten to carburetor with screw.

Screw

Assemble

One of These'

Low Points

Towards

Narrow

Edge of

Element

Assemble Element

So Lip Extends

Over Edge of Air

Cleaner Body

Lip Will Form

Protective Seal

When Cover Is

Assembled

FIGURE 28.

NEVER RUN YOUR ENGINE WITHOUT AIR

CLEANER COMPLETELY ASSEMBLED.

CARBURETOR ADJUSTMENTS

Minor carburetor adjustment may be required to

compensate for differences in fuel, temperature,

altitude and load.

NOTE

Adjust carburetor with fuel tank half

full of regular grade gasoline.

Initial Adjustment: See figure 29.

Close needle valve (turn clockwise) then open 1 Vz

turns (turn counterclockwise). This initial adjust

ment will permit the engine to be started and

warmed up before making final adjustment.

Final Adjustment: See figure 29.

With engine running at normal operating speed

(approximately 3000 RPM without load) close the

needle valve (turn clockwise) until engine starts to

lose speed (lean mixture). Then slowly open

needle valve (turn counterclockwise), past the

point of smoothest operation, until engine just

begins to run unevenly. This mixture should be

rich enough for best performance under load.

Hold throttle in idling position. Turn idle speed

adjusting screw until fast idle is obtained (1750

RPM). Test the engine under full load. If engine

tends to stall or die out, it usually indicates that

the mixture is slightly lean and it may be

necessary to open the needle valve slightly to

provide a richer mixture. This richer mixture may

cause a slight unevenness in idling.

Idle Adjustment Screw

Adjustment Screw

^

.

Turn in to

Needle Valve Increase Speed

FIGURE 29.

CHOKE-A-MATIC CONTROL ADJUSTMENTS

See figure 30.

Proper choke and stop switch operation is

dependent upon proper adjustment of remote

controls on the powered equipment.

“Choke”

Position

Choke

Clo

“Stop”

Position

stop

Switch

FIGURE 30.

14