Biscuit size selection, Biscuit location and layout, Biscuit location – Black & Decker 3382 User Manual

Page 9: Layout

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

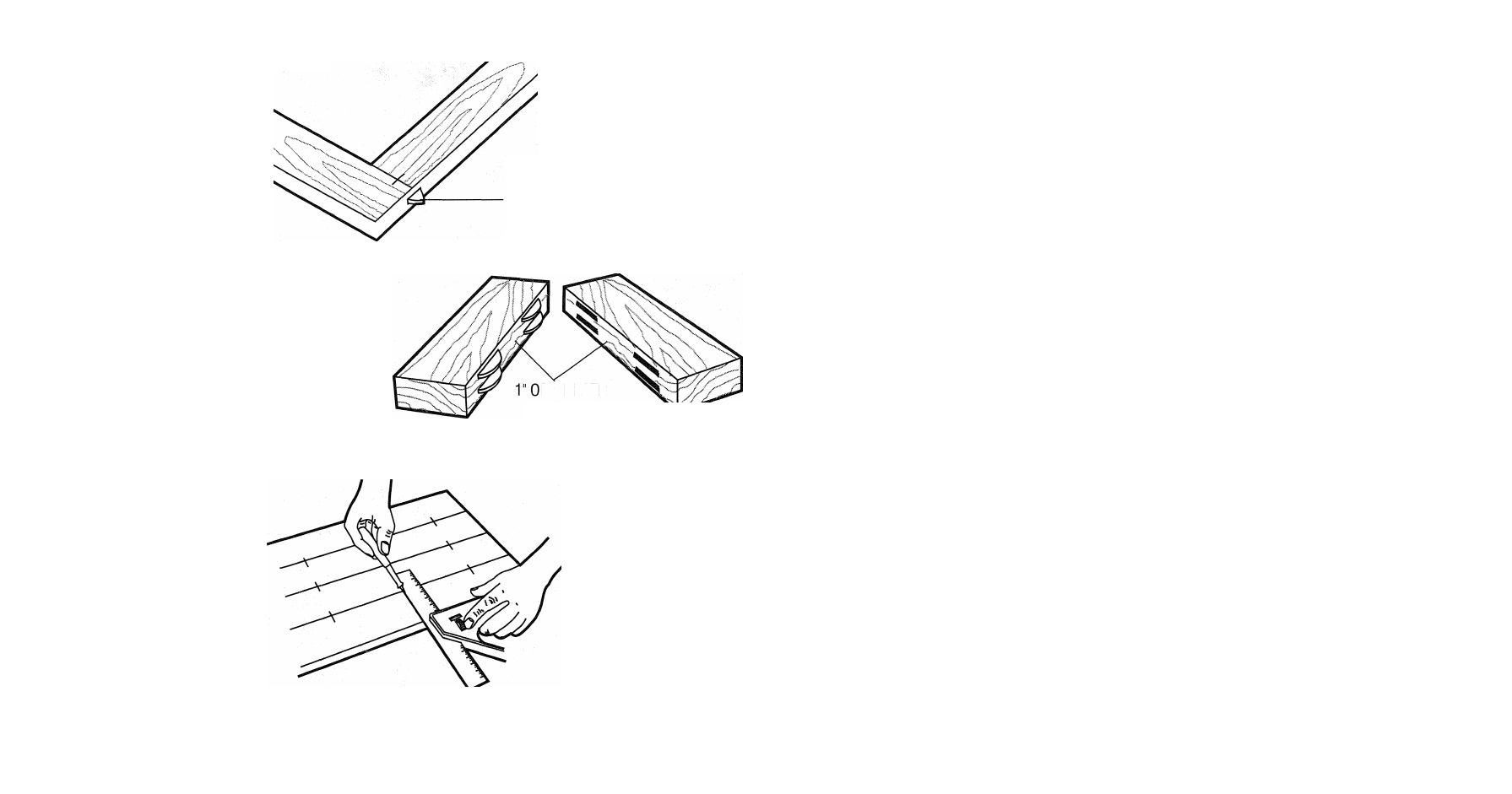

Figure 13

PROTRUDING BISCUIT

END (Trim off with saw

and sand smooth)

Figure 14

R GREATER

STOCK

THICKNESS

Figure 15

tions of joints that can be made with your plate joiner. We will limit our dis

cussion to six basic joints that can be used to build on and adapt to your own

applications. The following are some basic set-up steps that will apply to all

biscuit joints.

1. Biscuit Size Selection

As mentioned earlier, the three biscuit sizes are #0, #10 and #20. It is a good

rule of thumb to use the largest biscuit size that will physically fit in the appli

cation. Unless you are joining narrow face or picture frames or using 1/2"

(12.7mm) or thinner stock, you will find the #20 biscuit size to suit most

applications. After selecting the biscuit size, set the depth adjustment knob to

the corresponding size (see Controls section). Also, be sure the fine depth

adjustment is correctly set by first testing in a scrap piece. This is extremely

important as you do not want to discover during glue-up that your biscuit

slots are not quite deep enough.

2. Biscuit Location

and

Layout

Generally, biscuits may be spaced and located at your discretion. For edge

joints, a good rule is to space biscuits every 6-10" (150-250mm) on center. It

is further recommended that biscuits be placed so that the centerline of the

end biscuits is 2-3" (50-75mm) from the end of the work piece. When joining

face frames or picture frames where the work piece is narrow, you may have

to choose the smaller biscuit sizes to keep from breaking out on the end of the

joint. Breaking out should be avoided if possible, but if not you can assemble

the joint and trim off the exposed biscuit tip after the glue sets (See Figure 13).

When working with material up to 1/2" (25.4mm) thick, we advise to use a

single biscuit located in the approximate center of the material thickness. If

thicker stock is to be joined, you may choose to use 2 biscuits across the

thickness for greater strength (See Figure 14). Biscuit locations should be

marked by first positioning the mating pieces exactly as they are to be assem-