Corner joints (figure 21), Corner joints, Offset joints – Black & Decker 3382 User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Figure 20

Figure 21

Corner Joints

(Figure

21

)

Corner joints are another common and excellent application for biscuit join

ery. Follow the procedure below.

A. Arrange the work pieces exactly as they are to be joined.

B. Select the biscuit size and layout the biscuit locations.

C. Set up the tool by selecting the proper depth setting, adjusting the fence

to center on the stock thickness and setting the angle to 90°.

D. For this joint, you will make cuts into the edge of one work piece and the

face of another. The edge cut is performed the same as for edge to edge

joints. The face cut is made by clamping the work piece and aligning the

tool as shown in Figure 22. Turn the tool on, make the plunge cut and

repeat for each layout mark.

E. Glue, assemble and clamp the joint.

10

You may wish to have a deliberate offset between two work pieces. This is

easily accomplished with your plate joiner by performing the following steps.

A. Arrange the work pieces as they are to be assembled and layout the

biscuit locations.

B. Set up the tool by selecting the proper biscuit size and adjusting the

fence angle to 90°. Select the work piece that will be set back and adjust

the fence height to center the cut within the thickness of that piece.

C. Clamp the work piece, align the tool and make the plunge cut.

D. Next, adjust the fence up by an amount equal to the desired offset. Use

the scale and pointer located on the right side of the tool under the fence

lock knob.

E. Clamp the second work piece, align the tool and make the plunge cut.

F. Glue, assemble and clamp the joint.

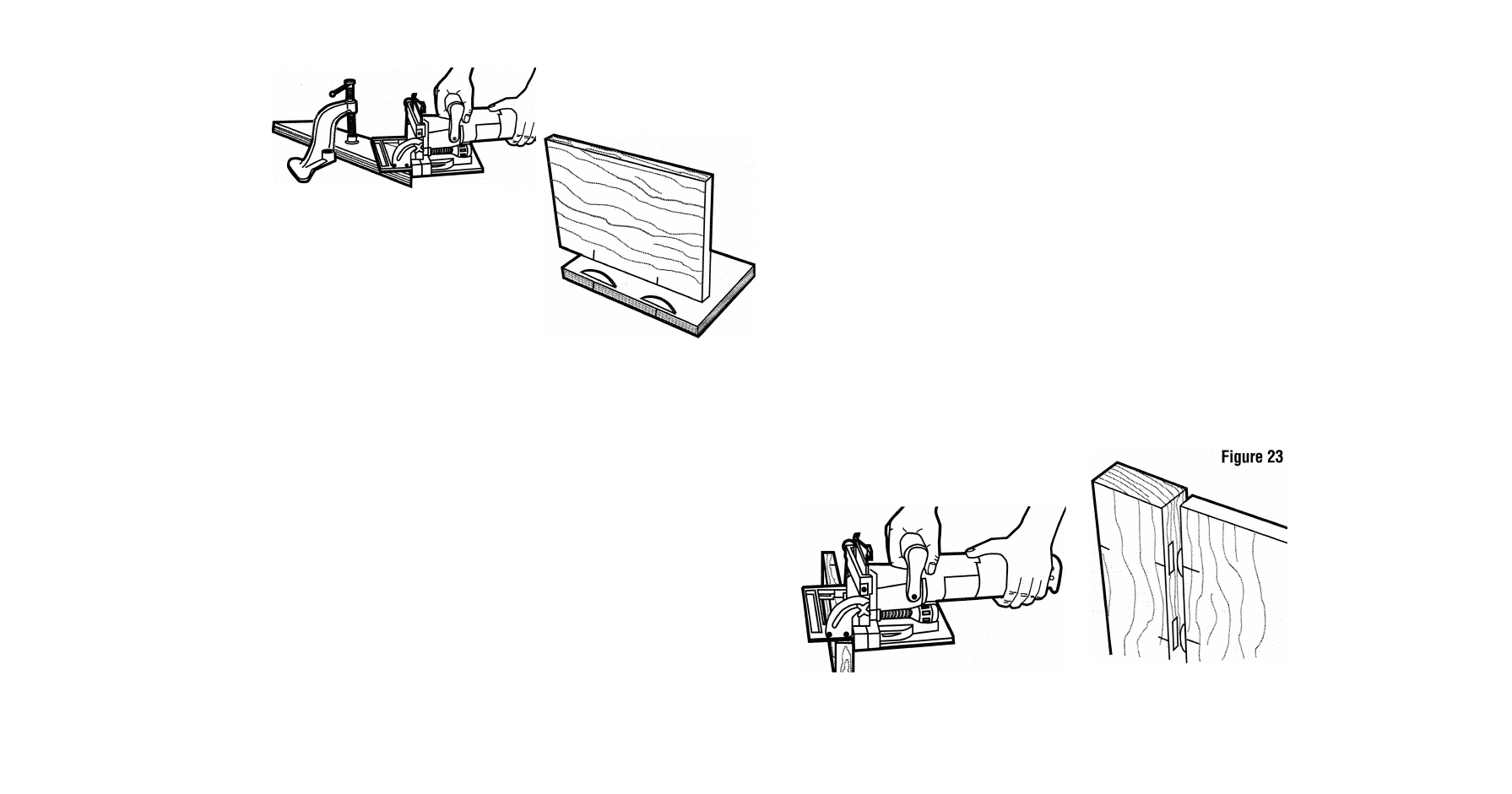

Offset Joints

(Figure 23)

Figure 22