Black & Decker 3382 User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

mate width of a #20 biscuit so that you’ll know where the edge of the blade is

and can prevent breakthrough. To avoid breaking through the work piece,

align the shoe so that neither outside mark extends beyond the end of the

work piece. If either side does, there is a good chance that the blade will break

through the surface and ruin your work.

DUST EXTRACTION

There are three options provided for collecting dust from your plate joiner as

described below.

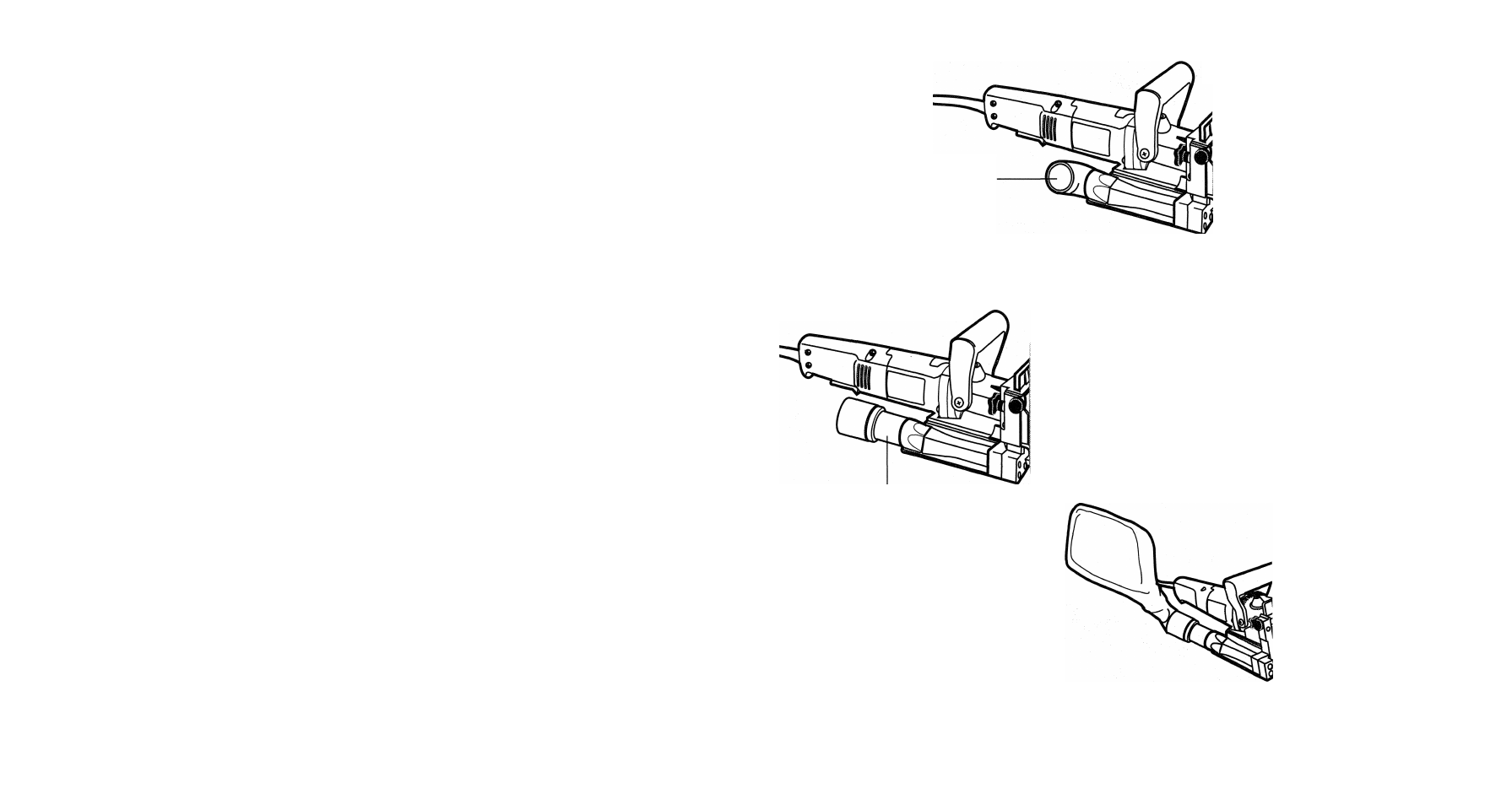

A. Adjustable Dust Port

(See Figure 10)

This attachment inserts into the dust exhaust port on the right side at the rear

of the base assembly and clicks into place. To remove, pull out firmly. The

adjustable port rotates easily to aim the dust in the most convenient direction

suitable for the particular application.

B. Vac Adaptor

(See Figure 11)

This attachment, when inserted as described above, allows the use of several

common sizes of vacuum hose to be attached for direct vacuum pick-up of

the dust.

C. Dust Bag

(See Figure 12)

The dust bag provided fits snugly over the dust adaptor described above. To

empty the bag, open the zipper underneath and dump dust out.

NOTE:

When the bag becomes full, the dust will back-up into the adaptor and

the exhaust port on the right rear of the tool. To clean out, turn off and unplug

the tool and remove packed dust. The bag will hold the dust generated from

approximately 70 to 100 #20 biscuit cuts before filling up.

Plate joiners are primarily used for making cabinetry and furniture, joining

millwork or other similar applications where a strong, accurate joint is

required in wood or wood by-products. There are literally hundreds of varia-

ROTATE ADJUSTABLE

DUST PORT FOR

DESIRED EXHAUST

DIRECTION

Figure 10

Figure 11

VACUUM HOSE

CONNECTION

Figure 12