Operating the cutter blade, Warning, Note – Bolens 137-465A User Manual

Page 10: Crankcase oil, Lubrication

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Step 6. Once the machine is in motion, remove

foot from the pedal. The mower will

now move ahead or to the rear, and the

use of the steering wheel will provide

directional control.

Step 7 .The mower is brought to a stop by

pressing your right foot against the brake

pedal and your left foot against the

clutch pedal. The drive belt will be

disengaged and the brake will be applied.

A

CAUTION

Gear changing should be done only

after the mower has been brought to

full stop. If the mower is not to be

used for a long period, place the

gear shift lever in NEUTRAL and

stop the engine. DO NOT leave the

machine on an incline.

OPERATING THE CUTTER BLADE

The cutting blades may be engaged while the

mower is moving or standing still. DO NOT

engage the cutting blades abruptly as the sudden

belt tension on the pulley may cause the engine to

stall.

t

WARNING

t

When The blade drive is engaged,

keep feet and hands away from the

discharge

opening

and

from

the

blade.

To

stop

the

blades,

move

the

lift

and

disengagement lever (figure 9) into the DISEN

GAGED position. This raises the deck and

disengages the blades.

NOTE

When the machine is used for other

than mowing operations the blade

drive should be disengaged.

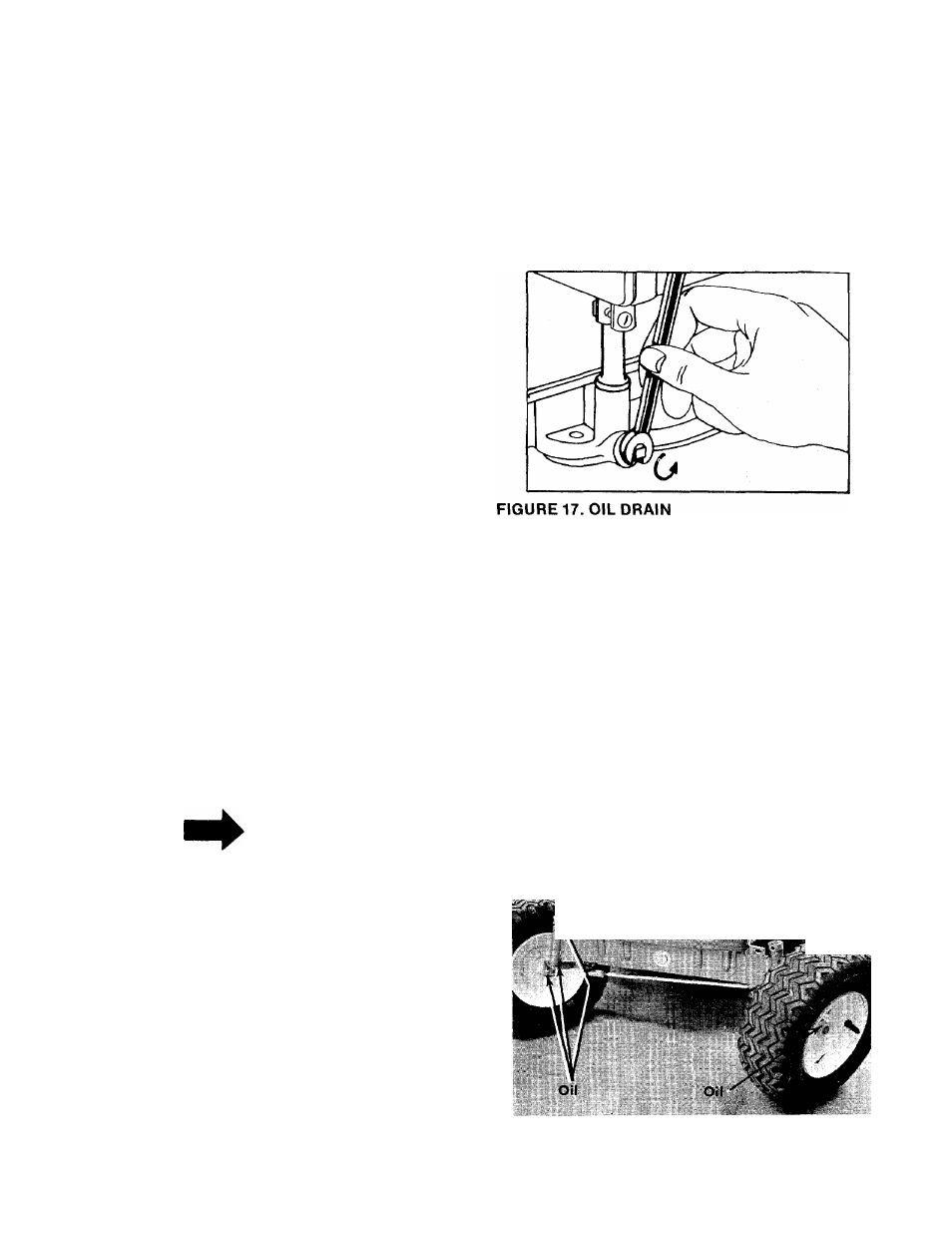

CRANKCASE OIL

To ensure maximum engine performance, perform

the following periodic maintenance:

Oil Check

Check the oil level in the crankcase before each

use of the machine and after every five hours of

operation. Oil should be kept between the add and

full marks on the dipstick.

After the first five hours of operating a new

engine, drain the oil (See figure 17.) from the

crankcase while engine is still hot and refill

crankcase with new oil; thereafter change the oil

every 25 hours of operation. This procedure

ensures for minimum wear of engine parts and

provides for virtually trouble-free operation. To

change the oil, proceed as follows;

Step 1. With the machine on level ground, place

a suitable metal container under the oil

drain plug, then remove the drain plug.

See figure 17.

Step 2. After the oil has been drained completely

from the crankcase, replace the drain

plug and tighten.

Step 3. Refill crankcase with 2V4 pints of good

quality, type MS, Engine oil into the

crankcase. Summer use SAE 30; Winter

(Below 40°F) use SAE 5W-20 or SAE

10W.

LUBRICATION

Lubricate the wheel bearings (2 per wheel) and the

upper and lower spindle bearings with SAE 30 oil

once a season. See figure 18.

\vi

ym

FIGURE 18. WHEEL AND SPINDLE BEARINGS

10