Throttle control adjustment, Carburetor adjustments, Lubrication – Bolens 112-428R372 User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

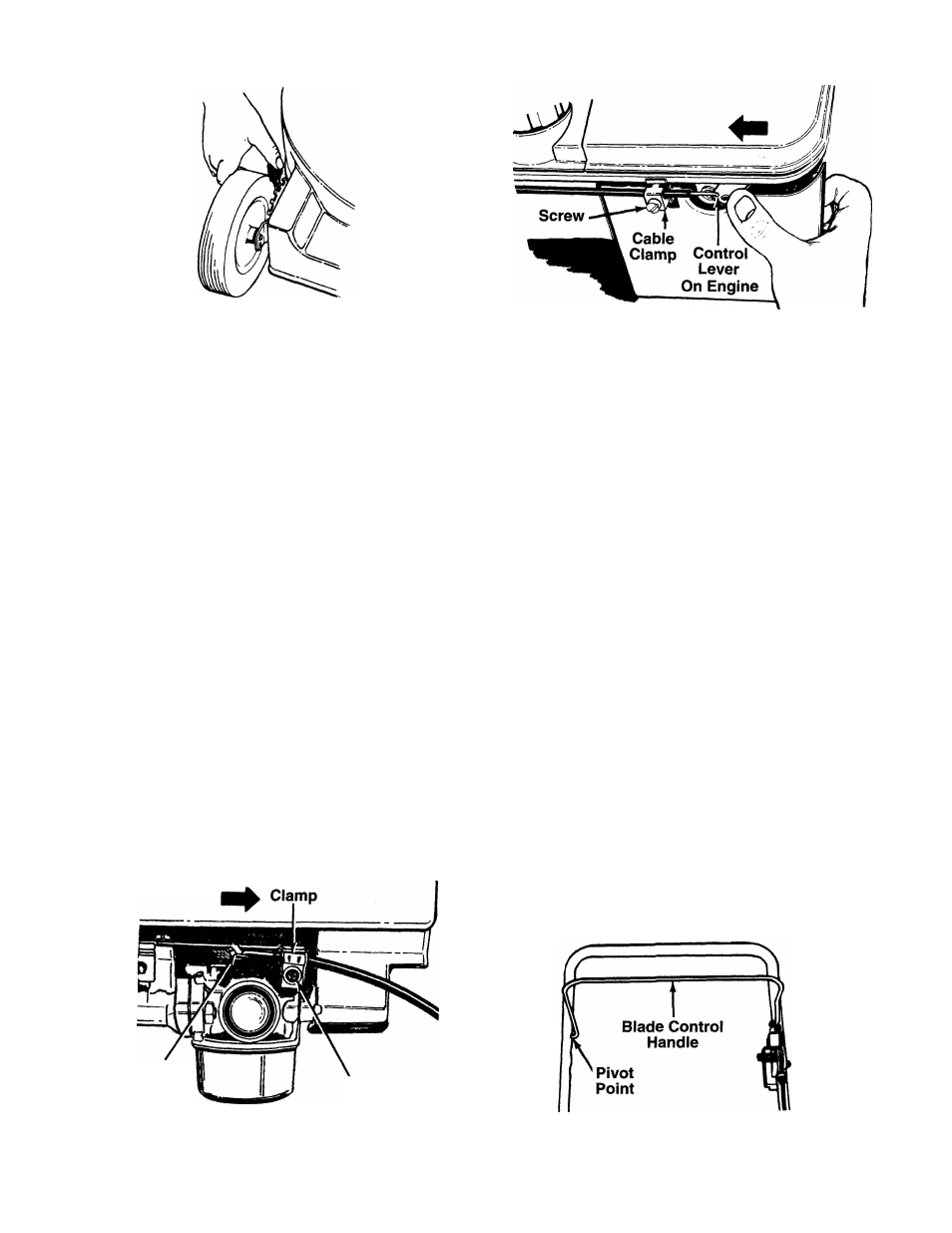

FIGURE 18.

THROTTLE CONTROL ADJUSTMENT

If the throttle control needs adjustment or if it has

been replaced, adjust as follows.

1. Remove the screw shown in figure 19. Remove

the cable clamp from the cable.

NOTE: If you have a Tecumseh engine, simply loosen

the screw shown in figure 19B so the cable will move

freely beneath the clamp. It is not necessary to

remove the screw and clamp completely.

2. Push the throttle control lever on the handle all

the way forward as far as it will go, then back it off

one “click.” Make certain the throttle control

lever remains in this position.

3. Push the control lever on the engine as far toward

the rear of the engine as it will go. Secure the

cable in this position with the cable clamp and

screw.

Cable

Control

Lever

Screw

On Engine

FIGURE 19A.—Briggs & Stratton Engines

FIGURE 19B.—Tecumseh Engines

CARBURETOR ADJUSTMENTS

A

WARNING: If any adjustments are made

to the engine while the engine is running

(e.g. carburetor), keep clear of all moving

parts. Be careful of heated surfaces and

muffler.

Minor carburetor adjustments may be required to

compensate for differences in fuel, temperature,

altitude and load. To adjust carburetor, refer to the

separate engine manual packed with your mower.

NOTE: A dirty air cleaner will cause an engine to run

rough. Be certain air cleaner is clean and attached to

the carburetor before adjusting carburetor. Refer to

the separate engine manual.

LUBRICATION

A

WARNING: Always stop engine and dis

connect spark plug wire before cleaning,

lubricating or doing any kind of work on

lawn mower.

Blade Control—Lubricate the pivot points on the

blade control handle and the brake cable at least

once a season with light oil. See figure 20. The blade

control must operate freely in both directions.

FIGURE 20.

11